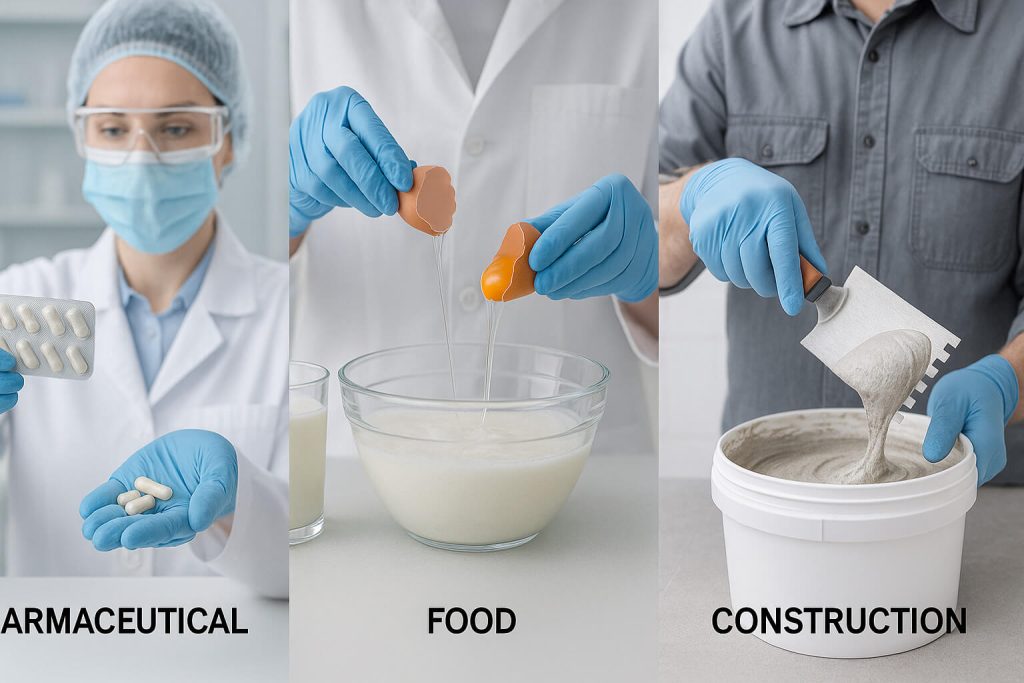

Hydroxypropyl Methylcellulose (HPMC) is an essential polymer used in multiple industries, including pharmaceuticals, food, and construction. This cellulose derivative is valued for its remarkable ability to form gels, its water solubility, and its viscosity-modifying capabilities. Whether you’re looking to optimize drug formulations, improve food texture, or enhance construction materials, HPMC plays a vital role in achieving the desired product quality. In this article, we’ll explore the key properties of HPMC and its various applications across industries, providing you with a clear understanding of how this versatile polymer benefits different sectors.

1. What is HPMC and Why is It Important in Various Industries?

Hydroxypropyl Methylcellulose (HPMC) is a water-soluble, semi-synthetic polymer made by chemically modifying cellulose, a natural polymer derived from plant fibers. By introducing hydroxypropyl and methyl groups to the cellulose structure, HPMC becomes highly soluble in cold water and forms gel-like substances at specific concentrations. This unique chemical structure allows it to perform a variety of functions across different industries.

HPMC’s importance lies in its versatility. In the pharmaceutical industry, it acts as a binder in tablet formulations, ensuring that active ingredients are evenly distributed and providing controlled drug release. In the construction sector, it is widely used as an additive in dry-mix mortars and adhesives, where it enhances the workability, water retention, and adhesion of materials. For the food industry, HPMC serves as a thickener, emulsifier, and stabilizer, improving the texture and shelf life of products like sauces, dressings, and ice cream.

The applications of HPMC are vast and its importance cannot be overstated. It enables industries to produce products with consistent quality and performance, meeting the growing demand for high-performance materials and formulations.

| Industry | Applications | Key Benefits |

|---|---|---|

| Pharmaceuticals | Binders, controlled-release agents | Consistency, controlled drug release |

| Construction | Mortars, adhesives | Improves workability, adhesion, water retention |

| Food | Emulsifiers, stabilizers, thickeners | Enhances texture, shelf-life, and mouthfeel |

2. What Are the Key Properties of HPMC That Make It Valuable?

The success of HPMC in various applications is largely due to its unique properties. Let’s break down the key characteristics that make it so valuable.

Water Solubility is one of the most important features of HPMC. Its ability to dissolve in cold and hot water allows for easy integration into formulations. This solubility makes it highly effective in industries such as pharmaceuticals, where it is used to form gels or suspensions for controlled drug release. In food, the water-soluble nature of HPMC ensures the consistency and stability of products.

Viscosity Control is another crucial property. HPMC’s ability to modify the viscosity of a solution is essential for its use in pharmaceutical tablets, where it determines the flowability of the ingredients. In the food industry, HPMC can be used to adjust the thickness of sauces and soups, allowing manufacturers to create the desired texture and mouthfeel.

Gel-Forming Ability makes HPMC a key ingredient in controlled-release drug delivery systems. The polymer forms a gel matrix that allows for the slow and consistent release of drugs over time. This ability is particularly valuable for pharmaceuticals that require sustained release for better therapeutic effects.

Lastly, Thermal Stability ensures that HPMC retains its functionality even when exposed to varying temperatures. This property is especially important in applications where products may undergo temperature fluctuations during manufacturing, transportation, or storage.

| Property | Functionality | Application |

|---|---|---|

| Water Solubility | Easily dissolves in cold and hot water | Pharmaceuticals, food, construction |

| Viscosity Control | Modifies thickness of solutions | Pharmaceuticals, food, adhesives |

| Gel-Forming Ability | Forms gels for sustained drug release | Pharmaceuticals, construction |

| Thermal Stability | Maintains stability at varying temperatures | Pharmaceuticals, food, construction |

3. How Does HPMC Work in the Pharmaceutical Industry?

HPMC is widely used in the pharmaceutical industry due to its excellent ability to form stable matrices that control the release of active ingredients. One of its most common applications is as a binder in tablet formulations. By binding the active ingredients and excipients together, HPMC ensures that the tablet maintains its structural integrity until it reaches the gastrointestinal tract.

HPMC also plays a significant role in controlled-release drug formulations. In these systems, HPMC is used to create a gel matrix that controls the release of the drug over an extended period. This is particularly beneficial for medications that need to be released slowly throughout the day, reducing the frequency of dosing and improving patient compliance.

In addition to its binding and controlled-release properties, HPMC is also utilized in pharmaceutical gels and topical preparations. It helps form stable gels that can hold active pharmaceutical ingredients, allowing for effective and sustained delivery through the skin.

| Pharmaceutical Application | Function | Benefit |

|---|---|---|

| Binder | Holds active ingredients together | Ensures tablet integrity, consistent release |

| Controlled Release | Regulates drug release rate | Sustained drug delivery, patient compliance |

| Gels and Topical Products | Forms stable matrices for drug delivery | Enhanced efficacy and stability |

4. What Are the Applications of HPMC in the Food Industry?

In the food industry, HPMC is used extensively as a thickener, emulsifier, and stabilizer. These properties are essential for maintaining the desired texture and consistency of many food products.

Thickening is one of the most common applications of HPMC in food. It is used to increase the viscosity of liquids such as sauces, dressings, and soups, ensuring that they have a smooth, creamy texture. HPMC’s ability to form a gel at certain concentrations makes it especially valuable in products that require a thick, stable consistency.

Emulsification is another key function of HPMC in food. It helps blend oil and water-based ingredients in products like mayonnaise, ice cream, and salad dressings. By stabilizing these emulsions, HPMC ensures that the oil and water phases don’t separate, maintaining a uniform texture.

Stabilizing properties make HPMC an excellent choice for improving the shelf life of food products. In ice cream, for example, HPMC prevents ice crystals from forming, resulting in a smoother product. Additionally, it can prevent phase separation in products like beverages and sauces, ensuring a consistent product throughout its shelf life.

| Food Application | Function | Benefit |

|---|---|---|

| Thickener | Increases viscosity in liquids | Ensures smooth texture, consistency |

| Emulsifier | Stabilizes oil-water mixtures | Prevents separation, uniform texture |

| Stabilizer | Enhances shelf-life and texture | Maintains consistency, improves mouthfeel |

5. How is HPMC Used in the Construction Industry?

In construction, HPMC is used primarily as an additive in dry-mix mortars, plasters, and adhesives. Its ability to modify viscosity and enhance water retention makes it invaluable in improving the workability and adhesion of construction materials.

In dry-mix mortars, HPMC increases the workability of the mix, making it easier to apply and spread. This is particularly important for products like tile adhesives, where ease of application and a smooth finish are critical for achieving a durable bond.

Water retention is another vital function of HPMC in construction. By retaining water in the mixture, HPMC ensures that the mortar or plaster has enough time to cure properly, even in dry conditions. This prevents premature drying, which can lead to cracks and weakened bonds.

Adhesion improvement is another benefit of using HPMC in construction materials. It increases the bonding strength between surfaces, ensuring that tiles, plaster, or other materials remain securely attached for longer periods.

| Construction Application | Function | Benefit |

|---|---|---|

| Dry-Mix Mortars | Improves workability, prevents clumping | Easy mixing and spreading |

| Plasters | Enhances water retention | Proper curing, prevents premature drying |

| Adhesives | Improves adhesion and bonding | Strong, durable bond, enhanced performance |

6. How Can HPMC Be Customized for Specific Industrial Applications?

One of the significant advantages of HPMC is its ability to be customized for different industrial applications. By adjusting certain properties of HPMC, such as its viscosity, dissolution rate, and degree of substitution, manufacturers can tailor the polymer to meet the specific needs of a product or process.

For example, in the pharmaceutical industry, customized HPMC grades can be developed to modify the release rate of drugs, allowing for controlled and sustained release. Similarly, in the food industry, HPMC can be adjusted to ensure the perfect consistency and texture for products like plant-based foods and gluten-free products.

In construction, the customization of HPMC can improve the workability and adhesion properties of dry-mix mortars, plasters, and adhesives, ensuring that the final product meets the required standards for durability and performance.

| Customization Aspect | Function | Benefit |

|---|---|---|

| Viscosity Control | Adjusts thickness of solutions | Tailored performance for various industries |

| Dissolution Rate | Controls drug release or emulsification rate | Extended release, consistent texture |

| Degree of Substitution | Influences solubility and gel formation | Fine-tuned properties for specific needs |

7. What Are the Environmental and Sustainability Benefits of HPMC?

As industries move toward more sustainable practices, HPMC stands out for its eco-friendly properties. HPMC is biodegradable, which means it decomposes naturally in the environment without causing harm or leaving toxic residues. This is a significant advantage over other synthetic polymers that can persist in the environment for long periods, contributing to pollution.

In green construction, HPMC is used in sustainable building materials due to its ability to enhance performance while being environmentally friendly. Additionally, HPMC’s plant-derived origins make it a more sustainable option compared to petroleum-based alternatives.

In the food industry, HPMC offers a plant-based alternative to animal-derived ingredients, such as gelatin, making it suitable for vegan and vegetarian products. This aligns with the growing consumer demand for plant-based, sustainable options.

| Environmental Benefit | Description | Application |

|---|---|---|

| Biodegradability | Breaks down naturally without leaving harmful residues | Construction, food |

| Eco-Friendly | Sustainable alternative to synthetic polymers | Green construction, sustainable food production |

8. What Are the Challenges in Using HPMC?

Despite its many advantages, there are some challenges associated with using HPMC in industrial applications. Consistency in large-scale production is one common issue. Inconsistent dissolution or variation in viscosity can lead to poor-quality products, especially in pharmaceuticals and food formulations.

Temperature sensitivity is another challenge. Excessive heat can degrade HPMC, reducing its effectiveness. Handling moisture is also crucial, as improper storage conditions can affect the polymer’s performance.

Lastly, supply chain issues may arise due to the variability in quality and costs of raw materials used to produce HPMC. These factors can affect production timelines and costs, making it essential for manufacturers to secure reliable sources of HPMC.

| Challenge | Cause | Solution |

|---|---|---|

| Inconsistent Production | Poor dissolution or viscosity variation | Ensure proper mixing, quality control |

| Temperature Sensitivity | Degradation at high temperatures | Maintain optimal storage conditions |

| Supply Chain Issues | Variability in raw material quality | Source from reliable suppliers, optimize production |

9. Are There Alternatives to HPMC?

While HPMC is highly effective, there are alternative polymers that offer similar properties. Methylcellulose (MC) is one such alternative, especially used in applications that require a gel-like structure. MC has the advantage of forming gels at higher temperatures, making it suitable for some specialized uses.

Carboxymethylcellulose (CMC) is another alternative, particularly known for its viscosity-modifying properties. CMC is used widely in the food and pharmaceutical industries, but it doesn’t offer the same gel-forming ability as HPMC.

Despite these alternatives, HPMC remains a preferred choice for many industries due to its unique combination of properties, including excellent water solubility, viscosity control, and gel-forming ability.

| Alternative | Key Features | Applications |

|---|---|---|

| Methylcellulose | Gel formation at higher temperatures | Food, pharmaceuticals |

| Carboxymethylcellulose | Viscosity control | Food, pharmaceuticals |

| HPMC | Water solubility, gel-forming | Pharmaceuticals, construction, food |

Conclusion

Hydroxypropyl Methylcellulose (HPMC) is a highly versatile polymer with a wide range of applications across pharmaceuticals, food, and construction. Its unique properties, including water solubility, viscosity control, and gel formation, make it essential in creating consistent, high-quality products. As industries increasingly focus on sustainability, HPMC’s biodegradability and eco-friendly nature further enhance its appeal. While challenges such as consistency and temperature sensitivity exist, HPMC’s numerous benefits and customizable nature make it an indispensable ingredient across various sectors.

FAQ

Q1: What is Hydroxypropyl Methylcellulose (HPMC)?

HPMC is a cellulose-derived polymer used as a binder, emulsifier, and stabilizer in various industries such as pharmaceuticals, food, and construction.

Q2: How does HPMC function in pharmaceutical applications?

HPMC serves as a binder in tablets and helps control the release of active ingredients in controlled-release formulations, ensuring consistent drug delivery.

Q3: What role does HPMC play in the food industry?

HPMC is used as a thickener, emulsifier, and stabilizer, improving texture and consistency in food products and acting as a vegan alternative to traditional ingredients like gelatin.

Q4: How does HPMC benefit the construction industry?

In construction, HPMC improves the workability and adhesion of mortars and adhesives, while also helping retain water for better curing and durability.

Q5: Are there alternatives to HPMC?

Alternatives like Methylcellulose and Carboxymethylcellulose offer similar properties, but HPMC remains the preferred choice due to its versatile functionality and performance in a wide range of industries.