مقدمة

ما هو HPMC K4M؟

هيدروكسي بروبيل ميثيل سلولوز K4M، المعروف باسم HPMC K4M، هو بوليمر متعدد الاستخدامات قائم على السليولوز مصمم لتحقيق الدقة والكفاءة. يُعرف بخصائصه الاستثنائية في تكوين الهلام والتكثيف والتثبيت، ويلعب دورًا محوريًا في مختلف الصناعات. من التركيبات الصيدلانية إلى التطبيقات الصناعية وصناعة الأغذية، يتميز HPMC K4M بقدرته على الذوبان في الماء البارد والتحكم في اللزوجة. تجعله قدرته على التكيف لا غنى عنه لإنشاء حلول مبتكرة وتحسين أداء المنتج.

لماذا يعد HPMC K4M مهمًا؟

يُعد HPMC K4M بمثابة العمود الفقري للعديد من المنتجات التي تؤثر على الحياة اليومية. في مجال المستحضرات الصيدلانية، يضمن إطلاق الدواء بشكل متحكم لتحقيق الفعالية المثلى. في صناعة الأغذية، يعزز القوام ويثبت المستحلبات. على المستوى الصناعي، يساهم في عوامل التثخين الفعالة والطلاء المستدام. بالنسبة للشركات التي تهدف إلى الدقة والاستدامة، يوفر HPMC K4M موثوقية لا مثيل لها، ويحول التحديات إلى حلول عملية. إنه أكثر من مجرد بوليمر، فهو حجر الزاوية للابتكار والتقدم.

نظرة عامة على HPMC K4M

تعريف هيدروكسي بروبيل ميثيل السليلوز

هيدروكسي بروبيل ميثيل سلولوز (HPMC) هو بوليمر مشتق من السليولوز يتميز بخصائصه الوظيفية الاستثنائية. تم تصنيعه من خلال عملية تعديل كيميائية دقيقة، وهو يجمع بين استقرار السليولوز مع زيادة قابلية الذوبان والتكيف. في جوهره الجزيئي، يتميز HPMC باستبدال متوازن لمجموعات الميثوكسيل والهيدروكسي بروبيل، مما يمنحه تنوعًا لا مثيل له. يسمح له هذا الهيكل الفريد بالتكثيف والاستقرار وتشكيل الهلام بكفاءة ملحوظة، مما يجعله لا غنى عنه في التطبيقات الصيدلانية والغذائية والصناعية.

ولكن ما الذي يميز الدرجة K4M عن المتغيرات HPMC الأخرى؟

The ‘K4M’ Label Explained

The “K4M” in HPMC K4M refers to its specific grade, a key indicator of its viscosity and intended applications. “K” denotes the viscosity range, while “4M” indicates a 4,000-centipoise viscosity level in a 2% aqueous solution. This grading ensures precision and consistency, making K4M particularly suitable for controlled-release drug formulations, high-performance coatings, and advanced thickening applications. By understanding this label, formulators can confidently select the right HPMC variant for their specific needs, ensuring optimal results across industries.

Now, let’s dive into the practical applications of HPMC K4M and its transformative impact.

الخصائص الأساسية لـ HPMC K4M

معدل اللزوجة في أفضل حالاته

تتميز مادة HPMC K4M بقدرتها على التحكم الدقيق في اللزوجة، حيث توفر لزوجة تبلغ 4000 سنتيبواز في محلول 2%. وهذا يجعلها خيارًا مثاليًا للتطبيقات الصناعية والصيدلانية. تضمن قدرتها على ضبط الاتساق بدقة تركيبات سلسة في كل شيء بدءًا من الأقراص ذات الإطلاق المتحكم فيه إلى الطلاءات عالية الأداء. سواء كان الأمر يتعلق بتثبيت المستحلبات أو تحسين خصائص التدفق، فإن براعتها في تعديل اللزوجة لا مثيل لها، مما يوفر الكفاءة والموثوقية.

ولكن كيف تتكامل هذه الخاصية مع وظائفها المتقدمة الأخرى؟

التجلط الحراري للإطلاق المتحكم فيه

من بين السمات البارزة لمادة HPMC K4M قدرتها على تكوين هلاميات مستقرة عند تعرضها للحرارة. وتعتبر خاصية التجلد الحراري هذه ذات قيمة لا تقدر بثمن في تركيبات الأدوية التي يتم التحكم في إطلاقها، حيث تساعد في إدارة إطلاق المكونات النشطة بمرور الوقت. وبعيدًا عن المستحضرات الصيدلانية، فإن ثباتها في درجات الحرارة العالية يضمن المتانة في التطبيقات الصناعية والغذائية، مما يوفر أداءً ثابتًا حتى في الظروف الصعبة.

هل تريد أن تعرف كيف تتكامل قابلية ذوبانه في الماء مع هذه القدرات؟ دعنا نلقي نظرة عن كثب.

ذوبان البوليمرات القائمة على السليلوز في الماء

باعتباره بوليمر قابل للذوبان في الماء، يذوب HPMC K4M بسهولة في الماء البارد، مما يخلق محاليل موحدة ومستقرة. تعمل هذه الخاصية على تعزيز تنوعه، مما يسمح له بالتكيف بسلاسة عبر تركيبات متنوعة. من المعلقات الصيدلانية إلى مثبتات الغذاء والمكثفات الصناعية، تضمن قابليته للذوبان في الماء سهولة الاستخدام مع الحفاظ على وظائف لا تشوبها شائبة.

بفضل هذه الخصائص مجتمعة، فإن التطبيقات المحتملة لـ HPMC K4M واسعة حقًا. دعنا نستكشف المكان الذي يتألق فيه هذا البوليمر متعدد الاستخدامات.

التطبيقات الرئيسية لـ HPMC K4M

التميز الصيدلاني

يُعد HPMC K4M بمثابة حجر الأساس في التركيبات الصيدلانية الحديثة.

- تركيبات الإطلاق الخاضع للرقابة إن قدراتها الفريدة على تكوين الهلام تجعلها مادة مساعدة مثالية للأدوية ذات الإطلاق المتحكم، مما يضمن إطلاق المكونات النشطة بشكل ثابت بمرور الوقت للحصول على التأثير العلاجي الأمثل.

- مادة رابطة ومفككة للأقراص يعمل HPMC K4M كعامل ربط قوي ومفكك دقيق، حيث يعزز قوة الأقراص مع تعزيز أنماط الذوبان الموحدة، مما يلبي المتطلبات الصارمة لجودة الأدوية.

- التوافق مع واجهات برمجة التطبيقات تشتهر مادة HPMC K4M بثباتها الكيميائي وطبيعتها غير التفاعلية، وتضمن توافقًا سلسًا مع المكونات الصيدلانية النشطة (APIs)، مما يضمن الفعالية ومدة الصلاحية.

تعتبر هذه الاستخدامات الدوائية مثيرة للإعجاب، ولكن كيف يعمل HPMC K4M في التطبيقات الصناعية؟

التطبيقات الصناعية خارج نطاق الأدوية

HPMC K4M هو حل متعدد الاستخدامات للتحديات الصناعية.

- عامل تكثيف فعال سواء في الدهانات أو الطلاءات أو المنظفات، توفر قوتها الاستثنائية في التكثيف ملمسًا وأداءً ثابتين، وتتكيف مع الاحتياجات الصناعية المتنوعة.

- السلوك الرومولوجي في البوليمرات من خلال ضبط خصائص التدفق بشكل دقيق، تعمل HPMC K4M على تعزيز معالجة المواد القائمة على البوليمر وسهولة استخدامها، مما يساهم في الكفاءة والدقة في التصنيع.

ولكن إمكاناتها لا تتوقف عند هذا الحد - فلنستكشف دورها في الأغذية ومنتجات العناية الشخصية.

الأغذية ومنتجات العناية الشخصية

كما يتألق HPMC K4M في تطبيقات الأغذية والعناية الشخصية.

- خصائص تشكيل الفيلم للطلاءات إن قدرتها على تشكيل أغشية واقية صالحة للأكل تعمل على إطالة عمر المنتج وتعزيز الملمس، مما يجعلها لا تقدر بثمن في طلاءات الأغذية والكبسولات الصيدلانية.

- فوائد الذوبان في الماء البارد إن طبيعتها سريعة الذوبان في الماء البارد تمكنها من الاندماج بكفاءة في الأطعمة الفورية ومستحضرات التجميل، مما يضمن تركيبات سلسة ومستقرة تلبي تفضيلات المستهلكين.

من الواضح أن قدرة HPMC K4M على التكيف تجعله عنصرًا أساسيًا في العديد من الصناعات. ولكن ما الذي يجعله موثوقًا به للغاية في هذه التطبيقات المتنوعة؟ دعنا نحلل دوره في تحسين أداء التركيبة.

حقائق سريعة حول HPMC K4M

ما الذي يميز K4M عن الدرجات الأخرى؟

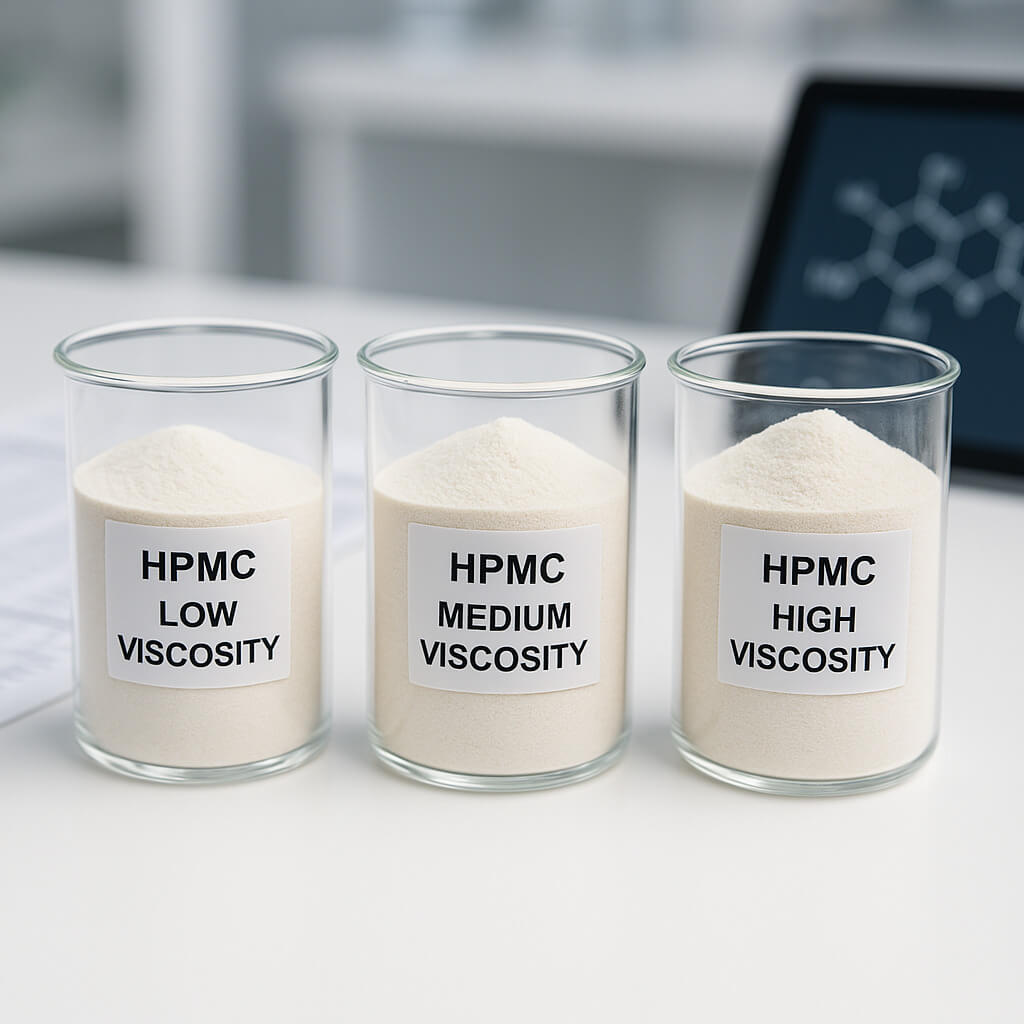

لا يتم إنشاء جميع درجات HPMC على قدم المساواة، وتتمتع K4M بميزة مميزة. حيث تحقق لزوجتها البالغة 4000 سنتيبواز التوازن المثالي للصيغ ذات الإطلاق المتحكم فيه، مما يجعلها الخيار المفضل للمبتكرين في مجال الأدوية والصناعة. وبالمقارنة مع الدرجات ذات اللزوجة المنخفضة، تتميز K4M بالثبات وقوة الهلام، في حين تجعلها لزوجتها الدقيقة أكثر ملاءمة للصيغ المعقدة من الخيارات ذات اللزوجة الأعلى. وهذا المزيج من التنوع والأداء هو السبب وراء تميزها باستمرار بين البوليمرات القائمة على السليلوز.

ولكن كيف يمكنك التأكد من أن K4M الذي تستخدمه يلبي أعلى المعايير؟

كيفية التعرف على HPMC K4M عالي الجودة

مع تزايد الطلب العالمي على HPMC، فإن التأكد من حصولك على K4M عالي الجودة أمر بالغ الأهمية. ابحث عن شهادات مثل ISO وGMP للتحقق من معايير الجودة. يوفر الموردون الموثوق بهم مواصفات مفصلة وتناسق الدفعات والشفافية في عمليات التصنيع. بالإضافة إلى ذلك، فإن إجراء اختبارات أساسية للزوجة والذوبان والنقاء يمكن أن يحمي من المنتجات دون المستوى، مما يضمن تحقيق تركيباتك للنتائج التي تحتاجها. K4M عالي الجودة ليس مجرد مادة - إنه ضمان للتميز في تطبيقاتك.

هل أنت مستعد لمعرفة كيف يمكن لـ HPMC K4M أن يرفع مستوى تركيباتك؟ دعنا نلخص مزاياه التي لا مثيل لها.

فوائد استخدام HPMC K4M

للمصممين

يُعد HPMC K4M بمثابة عامل تغيير كبير بالنسبة لمطوري المنتجات والمصنعين. حيث يضمن استقراره الذي لا مثيل له ثبات التركيبات عبر دفعات الإنتاج، مما يقلل من التباين ويعزز الموثوقية. كما أن خصائص البوليمر القابلة للتخصيص - مثل مستويات اللزوجة وعتبات التجلد الحراري - تمكن المصممين من تصميم حلول لتطبيقات متخصصة، سواء في المستحضرات الصيدلانية أو المنتجات الغذائية أو الطلاء الصناعي. تعمل هذه المرونة على تحويل الأفكار الإبداعية إلى منتجات قابلة للتطوير وعالية الأداء بسهولة.

ولكن ماذا يعني هذا بالنسبة للمستخدمين النهائيين الذين يعتمدون على هذه المنتجات؟

للمستخدمين النهائيين

بالنسبة للمستهلكين، فإن HPMC K4M تعني تجارب منتجات متفوقة. في مجال المستحضرات الصيدلانية، تضمن توصيل الأدوية بشكل آمن وفعال من خلال آليات الإطلاق المتحكم فيه. في منتجات الأغذية والعناية الشخصية، توفر ملمسًا وطول عمر ووظائف محسنة. سواء كان الأمر يتعلق بتمديد مدة صلاحية المنتج أو التطبيق السلس لمستحضر تجميلي، يستفيد المستخدمون النهائيون من الجودة المحسنة وسهولة الاستخدام التي توفرها HPMC K4M.

من الواضح أن HPMC K4M يسد الفجوة بين الابتكار ورضا المستخدم. دعونا نلخص أهم النقاط التي تم التوصل إليها لنرى لماذا لا غنى عنها.

التحديات والاعتبارات

فهم حدودها

على الرغم من أن HPMC K4M عبارة عن بوليمر متعدد الاستخدامات وعالي الأداء، إلا أنه ليس دائمًا الخيار الأمثل لكل تطبيق. فخصائصه في تكوين الهلام واللزوجة، على الرغم من كونها مفيدة في العديد من السيناريوهات، قد لا تناسب التركيبات التي تتطلب قابلية ذوبان سريعة أو استقرار شديد لدرجة الحموضة. بالإضافة إلى ذلك، قد يكون أقل فعالية في البيئات ذات القوة الأيونية العالية، والتي يمكن أن تتداخل مع أدائها. إن فهم هذه القيود يضمن اختيار البوليمر المناسب للاستخدام المقصود، مما يزيد من الكفاءة والنتائج.

إذن، كيف يمكنك تجنب الانتكاسات المحتملة عند الحصول على HPMC K4M؟

المخاطر المحتملة المرتبطة بالمنتجات ذات الجودة المنخفضة

أدى الطلب على HPMC K4M إلى ظهور معايير مختلفة للجودة في السوق، مما يجعل الاختيار الدقيق أمرًا بالغ الأهمية. يمكن أن تؤدي عمليات التصنيع دون المستوى إلى التلوث أو اللزوجة غير المتسقة أو انخفاض الوظائف، مما يعرض سلامة المنتج وسلامته للخطر. قد تفشل HPMC منخفضة الجودة أيضًا في تلبية المعايير التنظيمية، مما يؤدي إلى انتكاسات مكلفة للمصنعين. تعد الشراكة مع الموردين ذوي السمعة الطيبة وإجراء فحوصات الجودة الصارمة خطوات أساسية للتخفيف من هذه المخاطر وضمان الأداء الأمثل في تطبيقاتك.

من خلال التعرف على هذه التحديات، يمكنك اتخاذ قرارات مستنيرة للاستفادة من الإمكانات الكاملة لـ HPMC K4M. ولكن ما هي أفضل الممارسات لتحقيق أقصى استفادة من فوائدها؟ دعنا نستكشف ذلك.

الابتكارات في استخدام HPMC K4M

آفاق جديدة في أنظمة توصيل الأدوية

تعد HPMC K4M رائدة في مجال الابتكار الصيدلاني، مما يتيح تحقيق تقدم متطور في أنظمة توصيل الأدوية. يستكشف الباحثون إمكاناتها في إنشاء تركيبات ذكية وسريعة الاستجابة تطلق الدواء بدقة عندما وأينما كانت هناك حاجة إليه، مما يعزز النتائج العلاجية. يتم الجمع بين قدرتها على تشكيل مصفوفات الإطلاق المستمر مع تكنولوجيا النانو والهندسة الحيوية لتطوير علاجات الجيل التالي. من المتوقع أن تؤدي هذه الاختراقات إلى إحداث ثورة في الطب الشخصي، مما يجعل العلاجات أكثر أمانًا وفعالية وتركيزًا على المريض.

ولكن كيف تساهم HPMC K4M في التحول العالمي نحو الاستدامة؟

الاستدامة والتصنيع الصديق للبيئة

مع تحول الاستدامة إلى أولوية عالمية، تلعب HPMC K4M دورًا حيويًا في الكيمياء الخضراء والإنتاج الواعي للبيئة. يتبنى المصنعون مصادر السليلوز المتجددة ويعملون على تحسين العمليات الموفرة للطاقة للحد من البصمة الكربونية. توضح الابتكارات مثل مواد التغليف القابلة للتحلل البيولوجي والطلاءات الصناعية المستدامة كيف تساهم HPMC K4M في الإدارة البيئية دون المساس بالأداء. هذه الخطوات في التصنيع الصديق للبيئة لا تعيد تشكيل الصناعات فحسب - بل إنها تعيد تعريف مستقبل الإنتاج المسؤول.

ما هو التالي بالنسبة لشركة HPMC K4M مع استمرار الصناعات في الابتكار والتطور؟ دعونا نستكشف الاحتمالات المستقبلية.

دليل مرجعي سريع لـ HPMC K4M

لمحة عامة عن الميزات الرئيسية

يجمع HPMC K4M بين الدقة والتنوع، مما يجعله الحل الأمثل لمجموعة واسعة من التطبيقات. بفضل اللزوجة التي تبلغ 4000 سنتيبواز، فإنه يتفوق في التركيبات ذات الإطلاق المتحكم فيه، والمكثفات الصناعية، والمثبتات الصالحة للطعام. تشمل ميزاته البارزة قابلية الذوبان في الماء البارد، والتجمد الحراري، والتوافق الاستثنائي مع المكونات النشطة. يسلط هذا الجدول المرجعي السريع الضوء على خصائصه الرئيسية، مما يمنح صانعي التركيبات فهمًا واضحًا لسبب كون HPMC K4M لا غنى عنه في صناعاتهم.

ولكن ماذا لو كانت لديك مخاوف أو أسئلة محددة حول استخدامه؟

الإجابة على الأسئلة الشائعة

هل أنت مهتم بكيفية عمل HPMC K4M أو كيفية اختيار المورد المناسب؟ لدينا ما يلبي احتياجاتك. بدءًا من فهم لزوجته الفريدة إلى تقييم شهادات الجودة، يجيب هذا القسم على الأسئلة الأكثر شيوعًا. سواء كنت تتساءل عن دوره في المستحضرات الصيدلانية أو تطبيقاته في مستحضرات التجميل أو أفضل ممارسات التخزين، فإن هذه الأسئلة الشائعة تقدم رؤى واضحة وموجزة وقابلة للتنفيذ لمساعدتك في اتخاذ قرارات مستنيرة حول HPMC K4M.

هل أنت مستعد للتعمق أكثر؟ دعنا نستكشف التفاصيل الدقيقة لكيفية قدرة HPMC K4M على الارتقاء بتركيباتك.

خاتمة

لماذا HPMC K4M مهم؟

يُعد HPMC K4M حجر الزاوية في الابتكار، فهو يربط بين الوظائف والأداء في مختلف الصناعات الدوائية والمنتجات الغذائية والتطبيقات الصناعية. إن خصائصه الفريدة - مثل اللزوجة المتحكم فيها، والتخثر الحراري، والذوبان في الماء - تجعله لا غنى عنه لإنشاء تركيبات موثوقة وعالية الجودة. من تمكين توصيل الدواء بدقة إلى تعزيز متانة الطلاء، يعمل HPMC K4M على دفع التطورات التي تعمل على تحسين الكفاءة ورضا المستخدم. لا تكمن أهميته في تنوعه فحسب، بل في قدرته على رفع مستوى عدد لا يحصى من المنتجات التي نعتمد عليها يوميًا.

إذن، ما هي أفضل طريقة لدمج HPMC K4M في عملياتك؟

خطواتك القادمة

الآن بعد أن فهمت الإمكانات التحويلية لـ HPMC K4M، فقد حان الوقت لاستكشاف تطبيقاتها المصممة خصيصًا لتلبية احتياجاتك. سواء كنت من مصنعي المركبات الذين يبحثون عن حلول متطورة أو شركة تصنيع تهدف إلى الاتساق والجودة، فإن HPMC K4M هو الحل المناسب لك. تعاون مع الموردين الموثوق بهم، وأجرِ تقييمات الجودة، واكتشف الإمكانات الكاملة لهذا البوليمر الرائع في ابتكاراتك. الاحتمالات لا حصر لها - ابدأ رحلتك مع HPMC K4M اليوم.

هل أنت مستعد لاتخاذ الخطوة التالية؟ دع HPMC K4M تكون حجر الأساس لنجاحك.

الأسئلة الشائعة

1. ما هو الدور الأساسي لـ HPMC K4M في المستحضرات الصيدلانية؟

يعمل HPMC K4M كعامل إطلاق متحكم فيه، مما يضمن الإطلاق الثابت للمكونات النشطة بمرور الوقت. بالإضافة إلى ذلك، يعمل كعامل رابط ومفكك، مما يعزز قوة القرص وخصائص الذوبان.

2. كيف يمكنني ضمان جودة HPMC K4M قبل الشراء؟

التحقق من الشهادات مثل ISO وGMP من المورد. اطلب مواصفات المنتج التفصيلية وقم بإجراء اختبارات اللزوجة والنقاء والذوبان للتأكد من الاتساق والجودة.

3. هل HPMC K4M آمن للاستخدام في الأغذية ومنتجات العناية الشخصية؟

نعم، HPMC K4M هو مادة صالحة للأكل وغير سامة، مما يجعله آمنًا للاستخدام في تطبيقات مختلفة، بما في ذلك مثبتات الطعام ومستحضرات التجميل. طبيعته القابلة للذوبان في الماء تعمل على تحسين الملمس والاستقرار في هذه المنتجات.

4. هل يمكن لـ HPMC K4M أن يتحمل درجات الحرارة أو ظروف الرقم الهيدروجيني القصوى؟

يؤدي HPMC K4M أداءً جيدًا عبر مجموعة من درجات الحرارة بسبب خصائصه الحرارية. ومع ذلك، قد يواجه قيودًا في البيئات ذات القوة الأيونية العالية أو مستويات الأس الهيدروجيني الشديدة، مما قد يؤثر على وظائفه.

5. كيف تدعم HPMC K4M ممارسات التصنيع المستدامة؟

يتم استخلاص HPMC K4M من مصادر السليلوز المتجددة، وعمليات إنتاجه تتسم بكفاءة متزايدة في استخدام الطاقة. كما يساهم في المبادرات الصديقة للبيئة، مثل الطلاءات القابلة للتحلل البيولوجي والحلول الصناعية المستدامة.