مقدمة

نظرة أقرب على HPMC K4M

HPMC K4M، أو هيدروكسي بروبيل ميثيل سلولوز K4M، هو مشتق متخصص من السليولوز معروف بلزوجة دقيقة وتنوع استثنائي. تم تصميمه لتحقيق الاتساق والأداء، ويلعب دورًا محوريًا في تقنيات الصياغة الحديثة. إن قدرته على تعزيز الاستقرار والتحكم في آليات الإطلاق وضمان الموثوقية تجعله أداة لا غنى عنها للصناعات التي تسعى إلى الابتكار والتميز.

إعادة تعريف التركيبات الحديثة باستخدام HPMC K4M

في ظل المنافسة الشديدة التي نعيشها اليوم، حيث يلتقي الإبداع بالكفاءة، يعمل HPMC K4M على سد الفجوة بين الوظيفة والإبداع. يعمل هذا المكون الإضافي المتقدم على تحويل التركيبات من خلال تقديم خصائص ربط وتثخين وتكوين هلام متفوقة مع تعزيز التوافر البيولوجي وتحسين أنماط الإطلاق. وعلى عكس الإضافات التقليدية، لا يعد HPMC K4M مجرد مكون داعم، بل هو عامل تحويلي يرفع من مستوى التركيبات عبر الصناعات.

التأثير الواسع لـ HPMC K4M عبر الصناعات

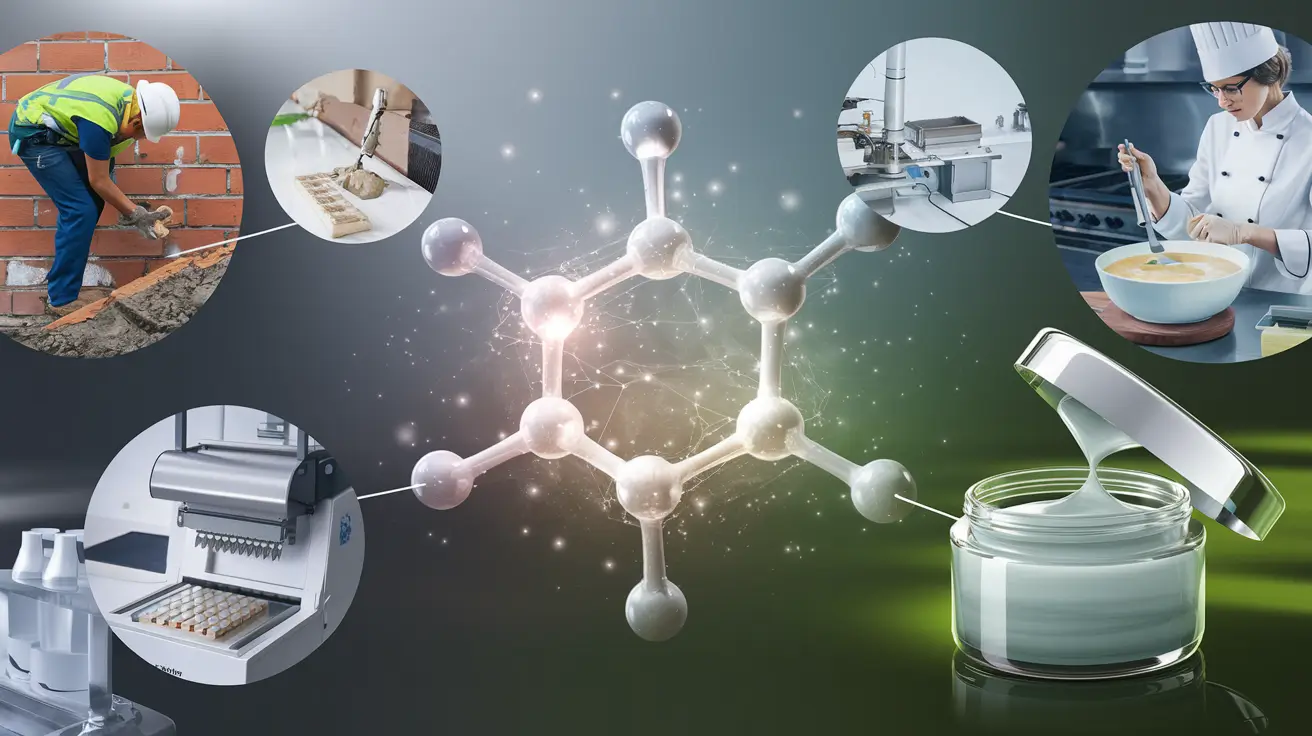

تتجاوز تنوعات HPMC K4M مجال المستحضرات الصيدلانية. ففي صناعة البناء، تعمل على تعزيز قوة الملاط وقابليته للعمل. وفي مستحضرات التجميل، تعمل على تحسين الملمس وتثبيت التركيبات. بالإضافة إلى ذلك، تجد تطبيقها في الأغذية والزراعة، حيث تتميز بقدرة لا مثيل لها على التكيف. وفي جميع هذه القطاعات، تعمل HPMC K4M على تمكين الابتكار، وتعزيز الكفاءة، ومساعدة الشركات على البقاء في المقدمة في الأسواق المتطورة باستمرار.

ما هو HPMC K4M؟

تعريف وتركيب هيدروكسي بروبيل ميثيل السليلوز K4M

HPMC K4M، اختصار لـ hydroxypropyl methylcellulose K4M، هو بوليمر متعدد الاستخدامات مشتق من السليلوز، وهو المركب العضوي الأكثر وفرة في الطبيعة. فهو يجمع بين خصائص مجموعات الميثيل والهيدروكسي بروبيل، مما يخلق مادة ذات قابلية ذوبان وثبات وأداء استثنائيين. يتفوق هذا البوليمر في التطبيقات التي تتطلب الإطلاق المتحكم فيه والتكثيف وتكوين الفيلم، مما يجعله عنصرًا أساسيًا في التركيبات المتقدمة عبر العديد من الصناعات.

ولكن ما الذي يميزها عند مقارنتها بالمواد الأخرى التي تعتمد على السليلوز؟

كيف يختلف عن مشتقات السليلوز الأخرى

في حين توفر العديد من مشتقات السليلوز فائدة كبيرة، فإن HPMC K4M يتميز بتوازنه الدقيق بين اللزوجة والأداء. وعلى عكس إيثرات السليلوز الأكثر بساطة، فإن بنيته تسمح بترطيب أفضل وتكوين هلام محسّن واستقرار حراري ملحوظ. هذه الخصائص الفريدة تجعله الخيار المفضل للتطبيقات الصعبة، حيث يكون الاتساق والدقة أمرًا بالغ الأهمية.

هل تريد أن تعرف لماذا تلعب اللزوجة دورًا بالغ الأهمية؟ دعنا نتعرف على المزيد.

أهمية درجة اللزوجة في HPMC K4M

إن درجة اللزوجة لـ HPMC K4M ليست مجرد رقم، بل هي أساس وظيفتها. يشير تصنيف "K4M" إلى اللزوجة المتوسطة إلى العالية، وهو عامل حاسم في تحديد سلوكه في التركيبات. تضمن هذه اللزوجة الإطلاق المتحكم فيه في الأقراص الصيدلانية، والملمس الأمثل في منتجات التجميل، والأداء القوي في مواد البناء، مما يثبت أن حتى أصغر التفاصيل مهمة عند صياغة الحلول المتطورة.

والآن، دعونا نستكشف كيفية ترجمة هذه الخصائص إلى تطبيقات في العالم الحقيقي.

الخصائص الأساسية التي تجعل HPMC K4M مميزًا

التجلد الحراري: أداء معزز في التطبيقات ذات درجات الحرارة العالية

تتميز مادة HPMC K4M بخواص التجلد الحراري الرائعة، مما يسمح لها بتكوين هلاميات مستقرة في درجات حرارة مرتفعة. هذه الخاصية الفريدة لا تقدر بثمن في التطبيقات مثل أنظمة الإطلاق المتحكم به للأدوية ومواد البناء، حيث يمكن أن تؤثر تقلبات درجات الحرارة على الأداء. تضمن قدرتها على الحفاظ على البنية تحت الحرارة نتائج متسقة عبر الاستخدامات المختلفة.

ولكن كيف يعمل عندما يصبح الملمس والتدفق أمرًا بالغ الأهمية؟

اللزوجة والسلوك الرومولوجي: كيف يعمل HPMC K4M على تثبيت التركيبات

إن اللزوجة الدقيقة والخواص الرومولوجية لـ HPMC K4M تجعله مثبتًا استثنائيًا. سواء في معلق دوائي أو كريم تجميلي، فإنه يوفر التوازن الصحيح بين التدفق والسمك، مما يضمن بقاء التركيبات موحدة وسهلة التطبيق. يمنح هذا التحكم في الملمس والسلوك تحت الضغط صانعي التركيبات دقة لا مثيل لها في إبداعاتهم.

ومع ذلك، فإن فوائدها لا تنتهي عند هذا الحد - دعونا نلقي نظرة على قدراتها على الاحتفاظ بالمياه.

الترطيب واحتباس الماء: الفوائد في كل من الصناعات الدوائية والبناء

تتميز مادة HPMC K4M بقدرتها على الاحتفاظ بالمياه، وهي خاصية بالغة الأهمية للتطبيقات التي تتراوح من الملاط الأسمنتي إلى أقراص الأدوية. وفي المستحضرات الصيدلانية، تضمن هذه الخاصية الذوبان والانطلاق المستمر، مما يعزز التوافر البيولوجي. وفي البناء، تعمل خصائص الترطيب على تحسين قابلية التشغيل وطول العمر، مما يجعلها خيارًا موثوقًا به لمواد البناء.

ولكن لماذا يعتبر مناسبًا بشكل خاص للتطبيقات الحساسة والمتنوعة؟

Biocompatibility and pH Stability: Why It’s Safe for Diverse Uses

باعتبارها مادة غير سامة ومتوافقة حيويًا، تعد HPMC K4M مثالية للتطبيقات الحساسة مثل المستحضرات الصيدلانية ومستحضرات التجميل. يضمن استقرارها عبر نطاق واسع من درجات الحموضة الموثوقية في البيئات ذات الحموضة أو القلوية المتفاوتة، مما يسمح لها بتقديم أداء ثابت. تجعلها هذه السلامة والقدرة على التكيف خيارًا عالميًا في جميع الصناعات.

والآن، دعونا نستكشف كيف تؤثر هذه الخصائص الأساسية على تطبيقاتها في العالم الحقيقي.

التطبيقات عبر الصناعات

المستحضرات الصيدلانية

يلعب HPMC K4M دورًا محوريًا في إحداث ثورة في التركيبات الصيدلانية. بصفته عاملًا يتم التحكم في إطلاقه، فإنه يضمن توصيل الدواء بدقة وثبات، مما يعزز النتائج العلاجية. تعد خصائصه المكونة للأغشية أساسية في الأدوية ذات الإطلاق المتأخر، حيث تحمي المكونات النشطة حتى تصل إلى موقع عملها المقصود. بالإضافة إلى ذلك، يعمل HPMC K4M على تحسين التوافر البيولوجي، مما يجعل الأدوية أكثر فعالية وكفاءة للمرضى.

لكن فوائدها تمتد إلى ما هو أبعد من الرعاية الصحية. فلنرى كيف تعمل في مجال البناء.

بناء

في صناعة البناء، تعتبر خصائص الاحتفاظ بالمياه التي تتمتع بها مادة HPMC K4M ذات قيمة لا تقدر بثمن لتطبيقات الأسمنت والملاط. من خلال الحفاظ على مستويات الرطوبة، تعمل على تعزيز قابلية التشغيل وتمنع الجفاف المبكر، مما يؤدي إلى هياكل أقوى وأكثر متانة. تجعلها قدراتها على التكثيف والربط الخيار المفضل لملاط الخلط الجاف، مما يضمن التوحيد وسهولة الاستخدام في المشاريع واسعة النطاق.

ولكن قدرتها على التكيف لا تتوقف عند هذا الحد - فكيف تعمل على تعزيز تركيبات الطعام؟

الأطعمة والمشروبات

يعمل HPMC K4M كمثبت ومستحلب متعدد الاستخدامات في قطاع الأغذية والمشروبات. فهو يحافظ على سلامة التركيبات المعقدة، ويضمن قوامًا متناسقًا ويمنع فصل المكونات. من الصلصات إلى الحلويات، يضمن إدراجه ملمسًا ممتازًا في الفم وعرضًا عالي الجودة، مما يجذب كلًا من الشركات المصنعة والمستهلكين على حد سواء.

وعندما يتعلق الأمر بالعناية الشخصية، فإن HPMC K4M يأخذ الوظائف إلى مستوى جديد.

مستحضرات التجميل والعناية الشخصية

في مستحضرات التجميل والعناية الشخصية، يوفر HPMC K4M تنوعًا لا مثيل له. إن قدرته على تكوين مواد هلامية مستقرة تجعله مفضلًا في المستحضرات والكريمات ومنتجات العناية بالبشرة الأخرى. علاوة على ذلك، فإن توافقه مع مجموعة واسعة من المكونات النشطة يضمن التكامل السلس في التركيبات المتنوعة، مما يعزز أداء المنتج ورضا المستهلك.

ولكن كيف يتمكن HPMC K4M من التفوق في مثل هذه التطبيقات المتنوعة؟ دعونا نكشف عن السبب العلمي وراء نجاحه.

نظرة عن قرب على HPMC K4M من الدرجة الصيدلانية

الشهادات ومعايير الجودة

تتميز مادة HPMC K4M عالية الجودة والموثوقية، حيث تلتزم بمعايير صارمة للتصديق والتنظيم. كما تضمن امتثالها لمتطلبات دستور الأدوية العالمي السلامة والفعالية، مما يجعلها الخيار الموثوق به لتركيبات الأدوية عالية المخاطر. ويستفيد المصنعون من اتساقها، وهو أمر بالغ الأهمية للحفاظ على سلامة المنتج.

ولكن كيف يترجم هذا إلى تحسين أداء الدواء؟

كيف يعمل HPMC K4M على تعزيز ملف حل الأدوية

من بين السمات البارزة لـ HPMC K4M قدرته على تحسين ملف ذوبان الأدوية بشكل كبير. من خلال تكوين مصفوفة بوليمرية موحدة، فإنه يضمن الإطلاق التدريجي والمتحكم للمكونات النشطة. لا تعمل هذه الوظيفة على تعزيز التوافر البيولوجي فحسب، بل تقلل أيضًا من تقلبات الجرعة، مما يضمن تأثيرًا علاجيًا ثابتًا.

ولكن فوائدها تذهب إلى أبعد من ذلك - دعونا نفحص دورها في تصميم الأجهزة اللوحية.

التأثير على زمن تفكك الأقراص والخواص الميكانيكية

يوفر HPMC K4M تحكمًا لا مثيل له في وقت تفكك الأقراص، مما يحقق التوازن المثالي بين البداية السريعة والإطلاق المستمر. تساهم خصائصه الميكانيكية أيضًا في متانة الأقراص، ومقاومة الكسر أثناء التصنيع والنقل. تجعله هذه الفوائد المزدوجة مكونًا أساسيًا في تطوير المنتجات الصيدلانية القوية والفعالة.

ما هو التالي؟ دعونا نستكشف كيف تؤثر هذه المزايا على التطبيقات في العالم الحقيقي.

تقنيات صياغة مبتكرة باستخدام HPMC K4M

أنظمة مصفوفة البوليمر: دورها في تركيبات الإطلاق المستمر

يعد HPMC K4M حجر الزاوية في تصميم أنظمة مصفوفة البوليمر، مما يتيح تركيبات دقيقة ذات إطلاق مستدام. تضمن قدرته على تكوين مصفوفة هلامية قوية وموحدة إطلاقًا متحكمًا للمكونات النشطة، مما يقلل من تكرار الجرعات ويحسن التزام المريض. هذه الميزة بالغة الأهمية في المستحضرات الصيدلانية الحديثة، حيث تعد المستويات العلاجية الثابتة ضرورية للفعالية.

ولكن كيف يساهم ذلك في تعزيز الابتكار في أنظمة توصيل الأدوية المعقدة؟

أنظمة توصيل الأدوية المتقدمة: مساهمات في العلاجات المبتكرة

في مجال أنظمة توصيل الأدوية المتقدمة، يعد HPMC K4M محفزًا للابتكار. فمن الأقراص متعددة الطبقات إلى أنظمة الإطلاق متعددة المراحل، يعزز هذا المنتج تنوع وفعالية العلاجات. كما أن توافقه الحيوي، إلى جانب خصائصه الاستثنائية في تكوين الفيلم والترابط، يسمح للمصممين بإنشاء منتجات متطورة تلبي متطلبات الطب المتطور.

السؤال الآن هو ما الذي يحمله المستقبل لـ HPMC K4M في مجال التقدم الدوائي؟

العلم وراء HPMC K4M

تكوين الهلام وذوبانه

يتمتع HPMC K4M بقدرة ملحوظة على تكوين هلاميات مستقرة في ظل الظروف الحرارية، وهي خاصية متجذرة في بنيته الجزيئية. فعند تعرضه للحرارة، تعاد ترتيب سلاسله لتكوين مصفوفة هلامية متماسكة، مما يضمن إطلاق الدواء بشكل يمكن التحكم فيه والتنبؤ به. وعلاوة على ذلك، يؤثر توزيع حجم جزيئات HPMC K4M بشكل كبير على أنماط الذوبان، حيث تعمل الجسيمات الدقيقة على تعزيز الترطيب بشكل أسرع وإطلاق أكثر اتساقًا، مما يجعله عاملًا حاسمًا في التركيبات الدقيقة.

ولكن كيف ترتبط اللزوجة بوظيفتها الشاملة؟

قياس اللزوجة

اللزوجة ليست مجرد رقم، بل هي مؤشر رئيسي للجودة والأداء في تركيبات HPMC K4M. تضمن قياسات اللزوجة الدقيقة الاتساق من دفعة إلى أخرى، وهو أمر ضروري في الصناعات عالية المخاطر مثل الأدوية. يعني الارتباط بين اللزوجة والأداء أن الاختلافات الطفيفة يمكن أن تؤثر على تدفق المنتج النهائي واستقراره وسلوكه، مما يؤكد أهمية التحكم الدقيق.

ومع ذلك، فإن اللزوجة وحدها لا تكفي - ماذا عن قوتها الميكانيكية واحتفاظها بالماء؟

الخواص الميكانيكية والترطيب

تعتبر الخواص الميكانيكية والترطيبية لـ HPMC K4M ضرورية لمتانة واستقرار الأقراص والتركيبات الأخرى. تعمل قدرتها على الاحتفاظ بالمياه على تعزيز سلامة البنية، ومنع التشقق أو الكسر. بالإضافة إلى ذلك، تضمن قوتها الميكانيكية أن الأقراص تتحمل ضغوط التصنيع والنقل، مما يوفر الموثوقية من الإنتاج إلى الاستخدام من قبل المريض.

والآن، دعونا نتعمق في كيفية ترجمة هذه المبادئ العلمية إلى تطبيقات في العالم الحقيقي.

فوائد مقارنة بالمنتجات المنافسة

المقارنة مع مشتقات السليلوز الأخرى

يتفوق HPMC K4M على مشتقات السليلوز الأخرى بفضل توازنه المتفوق بين الأداء والقدرة على التكيف. وفي حين توفر العديد من المواد المساعدة القائمة على السليلوز وظائف أساسية، فإن HPMC K4M يرفع من جودة التركيبات من خلال خصائصه التي يتم التحكم في إطلاقها، وقدراته الاستثنائية على تشكيل الأغشية، واستقراره المعزز للهلام. وهذا التميز يجعله الخيار الواضح للتطبيقات الصعبة في مختلف الصناعات.

ولكن ماذا عن تأثيره على كفاءة الإنتاج؟

فعالية التكلفة وسهولة الصياغة

تلتقي الكفاءة مع القدرة على تحمل التكاليف مع HPMC K4M. يقلل أداؤه الموثوق به من الحاجة إلى مثبتات أو عوامل تعديل إضافية، مما يبسط عملية التركيب ويقلل من تكاليف الإنتاج. بالإضافة إلى ذلك، فإن توافقه مع مجموعة واسعة من المكونات النشطة يبسط التكامل، مما يوفر الوقت والموارد للمصنعين.

ومع ذلك، فإن قوتها الحقيقية تكمن في قدرتها على الصمود في ظل الظروف المتنوعة.

التنوع في درجة الحموضة والظروف الحرارية

لا يمكن للعديد من المواد المساعدة أن تضاهي تنوع HPMC K4M عندما يتعلق الأمر باستقرار درجة الحموضة ودرجة الحرارة. فهو يظل فعالاً عبر طيف واسع من درجات الحموضة، مما يجعله مناسبًا للتركيبات الحمضية والمحايدة والقلوية. تضمن مرونته الحرارية الاتساق في العمليات ذات درجات الحرارة العالية، مما يوفر نتائج استثنائية حتى في ظل الظروف الصعبة.

والسؤال الآن هو كيف تترجم هذه المرونة إلى قيمة طويلة الأجل بالنسبة للمصنعين؟

أمثلة واقعية لاستخدام HPMC K4M

دراسات حالة ناجحة في تركيبات الأدوية

لقد أثبتت مادة HPMC K4M أنها لا غنى عنها في الابتكارات الصيدلانية، حيث أكدت العديد من دراسات الحالة فعاليتها. ففي الأقراص التي يتم التحكم في إطلاقها، تضمن المادة توصيل الدواء بدقة لفترات طويلة، مما يحسن النتائج العلاجية وامتثال المريض للعلاج. وقد أدى دورها في تحسين ملفات الذوبان إلى تقدم رائد في التوافر البيولوجي للأدوية المنقذة للحياة، مما عزز سمعتها كمواد مساعدة موثوقة.

ولكن كيف يعمل هذا في البيئات الصناعية واسعة النطاق؟

التطبيق في المنتجات الصناعية واسعة النطاق

إلى جانب المستحضرات الصيدلانية، يعد HPMC K4M حجر الزاوية في التركيبات الصناعية واسعة النطاق. وفي صناعة البناء، يعمل على تحسين أداء الأسمنت والملاط، مما يوفر احتباسًا متفوقًا للماء وقابلية التشغيل. وقد أدى استخدامه في المنتجات الغذائية ومستحضرات التجميل والعناية الشخصية إلى نتائج ثابتة وعالية الجودة، مما يُظهر تنوعه وموثوقيته في تلبية المتطلبات المتنوعة للأسواق العالمية.

ويبقى السؤال الرئيسي: ما هي الابتكارات المستقبلية التي سيمكنها HPMC K4M؟

التحديات والحلول

التحديات الشائعة في استخدام HPMC K4M

حتى المكونات القوية مثل HPMC K4M تأتي مع نصيبها من التحديات. قد يواجه المصممون مشكلات مثل التكتل أثناء الترطيب، أو اللزوجة غير المتناسقة، أو الصعوبات في تحقيق التشتت المنتظم في البيئات عالية القص. بالإضافة إلى ذلك، قد يتطلب ضمان التوافق مع المكونات النشطة المحددة أو الحفاظ على الاستقرار في الظروف القاسية تعديلات دقيقة.

إذن، كيف يمكننا معالجة هذه العقبات بفعالية؟

نصائح لتحسين خصائصه في التركيبات

إن التغلب على هذه التحديات أمر ممكن تمامًا باستخدام الاستراتيجيات الصحيحة. إن توزيع HPMC K4M مسبقًا في سوائل غير مذيبة أو مزجه بمكونات جافة أخرى يمكن أن يمنع التكتل ويعزز التجانس. إن إجراء قياسات دقيقة للزوجة وضبط ظروف المعالجة، مثل سرعة الخلط ودرجة الحرارة، يضمن الاتساق. إن التعاون مع الموردين للحصول على درجات مخصصة أو إرشادات خاصة بالتطبيق يمكن أن يزيد من تحسين أدائه، مما يفتح المجال أمام الإمكانات الكاملة لـ HPMC K4M في تركيباتك.

الخطوة التالية واضحة: دعنا نستكشف كيف تترجم هذه الحلول إلى نتائج أفضل لمنتجاتك.

التأثير البيئي والاستدامة

قابلية التحلل البيولوجي لـ HPMC K4M

تتميز مادة HPMC K4M ليس فقط بوظيفتها ولكن أيضًا بسمعتها البيئية. فهي مشتقة من السليلوز، وهو مورد طبيعي متجدد، وتتميز بقدرة ممتازة على التحلل البيولوجي. وهذا يضمن تحلل المنتجات التي تستخدم مادة HPMC K4M بأمان في البيئة، مما يقلل من بصمتها البيئية مع تلبية الطلب المتزايد على الحلول المستدامة عبر الصناعات.

ولكن كيف يتوافق إنتاجها مع المعايير الصديقة للبيئة؟

الممارسات الصديقة للبيئة في إنتاجها وتطبيقها

يركز إنتاج HPMC K4M على الممارسات الصديقة للبيئة، مع الحد الأدنى من النفايات والالتزام باللوائح البيئية الصارمة. كما أن استخدامه في التركيبات يدعم الاستدامة من خلال تعزيز الكفاءة وتقليل هدر المواد وإطالة عمر المنتج. بالنسبة للصناعات التي تتطلع إلى تحقيق التوازن بين الأداء والمسؤولية البيئية، يوفر HPMC K4M التآزر المثالي بين الابتكار والاستدامة.

ما هو التالي؟ دعونا نفكر في الكيفية التي يمكن بها لشركة HPMC K4M أن تقود مبادرات الاستدامة المستقبلية عبر القطاعات.

نصائح عملية للعمل مع HPMC K4M

توصيات التخزين والمناولة

يعد التخزين والتعامل السليم مع HPMC K4M أمرًا بالغ الأهمية للحفاظ على جودته وأدائه. يجب حفظه في بيئة باردة وجافة، بعيدًا عن أشعة الشمس المباشرة والرطوبة، لمنع التكتل أو التدهور. يساعد استخدام حاويات محكمة الغلق في الحفاظ على سلامته، مما يضمن بقائه متماسكًا وجاهزًا لاحتياجات التركيبة الدقيقة.

ولكن كيف يمكنك تحقيق أقصى قدر من الأداء أثناء صياغته؟

أفضل الممارسات لدمجها في التركيبات

يتطلب دمج HPMC K4M في التركيبات الاهتمام بالتفاصيل. يمكن أن يمنع خلطه مسبقًا بمكونات جافة أخرى التكتل، بينما يضمن إدخاله تدريجيًا في السوائل في درجات حرارة محكومة التشتت المتساوي. يمكن أن يؤدي استخدام معدات الخلط عالية القص إلى تعزيز الترطيب وتطوير اللزوجة، وتحسين وظائفه. يضمن اتباع أفضل الممارسات هذه أن يعمل HPMC K4M بسلاسة، مما يوفر النتائج المرجوة عبر تطبيقات متنوعة.

هل تحتاج إلى مزيد من الأفكار القابلة للتنفيذ؟ دعنا نستكشف التقنيات المتقدمة لتحسين استخدامها.

الأسئلة الشائعة حول HPMC K4M

ما الذي يجعل HPMC K4M فريدًا مقارنة بدرجات اللزوجة الأخرى؟

تتميز مادة HPMC K4M بنطاق اللزوجة المتوازن، مما يوفر الثبات والأداء المتفوق. تضمن اللزوجة المتوسطة إلى العالية التحكم الدقيق في تكوين الهلام وأنماط الإطلاق والخصائص الميكانيكية. وهذا يجعلها الخيار الأفضل للتطبيقات التي تتطلب نتائج ثابتة وموثوقة.

هل HPMC K4M مناسب للمستحضرات الحساسة للحرارة؟

نعم، تتميز مادة HPMC K4M بالكفاءة في البيئات الحساسة لدرجة الحرارة. حيث تمكنها خصائص التجلد الحراري من البقاء مستقرة وفعّالة، حتى في ظل ظروف متقلبة أو درجات حرارة عالية. وتسمح لها هذه الخاصية بتكوين مصفوفات هلامية قوية، مما يجعلها مثالية للمنتجات التي تتطلب مرونة في الأداء تحت الضغط الحراري.

كيف يعمل HPMC K4M على تحسين التوافر البيولوجي؟

يعمل HPMC K4M على تعزيز التوافر البيولوجي من خلال إنشاء أنظمة إطلاق متحكم بها تعمل على توصيل المكونات النشطة بشكل ثابت بمرور الوقت. يعمل هذا الإطلاق المطول على تحسين معدلات امتصاص الدواء، والحفاظ على مستويات علاجية في الجسم لفترات طويلة. كما تعمل قدرته على تثبيت وتحسين ملفات الذوبان على تعزيز دوره في تعزيز التوافر البيولوجي.

خاتمة

ملخص لماذا HPMC K4M هو تحويلي

لقد أثبت HPMC K4M أنه أكثر من مجرد مادة مساعدة، بل إنه مكون يغير قواعد اللعبة ويعيد تعريف ما هو ممكن في التركيبات الحديثة. من قدرته الفريدة على التماسك الحراري والتحكم في اللزوجة إلى تنوعه عبر الصناعات، يقدم HPMC K4M أداءً ثابتًا وحلولًا مبتكرة. إن دوره في تعزيز الإطلاق المتحكم فيه والتوافر البيولوجي والسلامة البنيوية يجعله لا غنى عنه لصانعي التركيبات الذين يسعون إلى التميز.

ولكن كيف يمكنك الاستفادة من هذه الإمكانية التحويلية؟

نداء إلى صانعي الأدوية لاستكشاف إمكاناتها

إن الإمكانيات التي يوفرها HPMC K4M هائلة بقدر الصناعات التي يخدمها. سواء كنت تبتكر في مجال الأدوية أو البناء أو العناية الشخصية، فإن هذا البوليمر يوفر منصة قوية لرفع مستوى تركيباتك. لا تفوت الفرصة لدمج هذا المكون التحويلي ودفع حدود ما يمكن لمنتجاتك تحقيقه.

هل أنت مستعد لاعتماد معيار جديد للجودة والأداء؟

التشجيع على إعطاء الأولوية لمنتجات HPMC K4M عالية الجودة من أجل الابتكار

يعد اختيار HPMC K4M المناسب أمرًا بالغ الأهمية لإطلاق العنان لإمكاناته الكاملة. أعطِ الأولوية للجودة والموثوقية لضمان أن تركيباتك لا تلبي التوقعات فحسب بل تتجاوزها. من خلال الاستفادة من الخصائص المتفوقة لـ HPMC K4M، فأنت لا تقوم فقط بصياغة المنتجات - بل أنت تقود الابتكار وتشكل مستقبل صناعتك.

دعونا نعمل معًا على إنشاء الموجة التالية من الحلول التحويلية.