Understanding HPMC 606 and its role in industrial formulations is essential for many decision-makers in sectors like construction, pharmaceuticals, and food. This article dives into the technical specifics and practical applications of HPMC 606, helping you see its value in real-world industrial processes. Let’s get down to business and explore what makes this polymer relevant for your operations, how it performs, and why it deserves your attention. You will gain clarity on its essential properties, manufacturing methods, industry applications, and handling advice, all backed by detailed examples and data.

1. What Is HPMC 606?

Hydroxypropyl methylcellulose 606, or HPMC 606, is a modified cellulose polymer produced through chemical processes modifying natural cellulose. Here’s the crux of the matter: It offers water solubility combined with excellent film-forming, thickening, and binding characteristics, making it invaluable in industrial contexts. What separates HPMC 606 from other HPMC grades is its specific viscosity and substitution rates, tailored for optimal performance in complex formulations.

This material is distinguished by its inertness, biodegradability, and compatibility with a wide range of ingredients, making it versatile for different industries. For instance, in construction, it helps thicken mortars, enhancing texture and workability. In pharmaceuticals, it acts as a binder or coating. Food industries use it for stabilizing or thickening edible products.

To put it in perspective, HPMC 606 reacts predictably with water without forming gels at room temperature, which is vital for process control. Its thermal stability up to certain temperatures adds to its broad appeal.

Case study one involves a manufacturer of plaster products who switched to HPMC 606 from an older polymer, resulting in improved workability and less shrinkage in final products. Another pharma company used HPMC 606 to enhance tablet coating uniformity, improving dissolution rates. A food processing firm noted better texture consistency in sauces after adding this polymer.

| ملكية | وصف | أهمية |

|---|---|---|

| اللزوجة | درجة اللزوجة المتوسطة | Controls thickness |

| الذوبان في الماء | Fully soluble in cold water | Essential for processing |

| الاستقرار الحراري | Stable up to 180°C | Suitable for hot applications |

| التوافق | Works with most solvents and additives | Versatile for formulation |

You might be wondering how these properties translate into tangible benefits. The truth is, HPMC 606 enables manufacturers to fine-tune rheological behavior in formulations, ensuring predictable performance every time.

2. How Does HPMC 606 Function in Industrial Formulations?

It’s crucial to understand how HPMC 606 performs within product matrices. Let me explain the core workings: HPMC 606 acts primarily as a thickening agent and binder, imparting viscosity control and stabilization to formulations. By interacting with water molecules, it forms a network that modifies flow properties without causing gelation under typical conditions, which is a key difference from other cellulose-based polymers.

HPMC 606 improves the physical consistency and durability of industrial products by controlling water retention and enabling uniform mixing. For example, in construction mortars, it prevents segregation of weighty particles and improves adhesion to substrates. In pharmaceutical suspensions, it maintains particle dispersion longer, preventing settling. Food sauces achieve a smooth, uniform texture thanks to its stabilizing effect.

Consider a paint manufacturer who added HPMC 606 to improve leveling and prevent sagging during application. Another example is a manufacturer of adhesive sealants, which used this polymer to enhance bonding strength and flexibility after curing, leading to superior end-product life.

What’s more, HPMC 606 influences drying times and crack resistance. In construction, this means fewer defects and longer-lasting materials. Data from one supplier showed a 20% reduction in surface fissures in plaster formulations using this polymer, improving customer satisfaction and cost-efficiency.

| مجال التطبيق | Effect of HPMC 606 | فائدة |

|---|---|---|

| Mortar and plaster | Enhances water retention and viscosity | Improves workability and reduces cracking |

| Paints and coatings | Controls flow and prevents sagging | Ensures smooth, even coating |

| المستحضرات الصيدلانية | Stabilizes suspensions and prevents settling | Ensures dosage consistency |

You might find it useful to note that processing compatibility matters here; HPMC 606’s ease of incorporation into water-based systems speeds up manufacturing without special equipment.

3. Why Do Industries Choose HPMC 606?

Choosing the right additive can make or break product quality. وهنا الحقيقة: Industries prefer HPMC 606 primarily for its dependable technical performance and adaptability. It consistently beats alternatives in terms of compatibility, stability, and regulatory clarity.

First, HPMC 606 works well with a wide variety of other raw materials, reducing formulation risks. For instance, it doesn’t react adversely with acrylics or plasticizers. This characteristic broadens its use in multiphase systems such as specialty coatings or layered pharmaceuticals.

Second, the polymer adheres to global regulatory standards, simplifying compliance for industrial buyers who face complex legal environments. This means fewer delays in market entry—a big advantage in fast-moving sectors like pharma.

Third, manufacturing processes benefit from HPMC 606’s reproducibility and consistency. One construction chemical producer reported cutting batch variability by over 15% when switching to this polymer, resulting in lower waste and improved quality control metrics.

Industries especially value its inertness and non-toxicity. Construction materials don’t need extensive hazard precautions. Pharma formulators rely on its non-reactive profile for parenteral and oral drugs. Food applications can also use food-grade HPMC 606 variants to meet safety requirements.

| صناعة | Key Reasons for Choosing HPMC 606 | Example Outcome |

|---|---|---|

| بناء | Compatibility, improved consistency | Reduced product rework |

| المستحضرات الصيدلانية | Regulatory compliance, inertness | Faster drug approval process |

| Food & Packaging | Food safety compliance, stability | Extended shelf life |

Here’s the kicker: manufacturers benefit from reduced risk and streamlined formulation processes while delivering higher-performing products to end-users.

4. How Is HPMC 606 Manufactured and Processed?

Manufacturing HPMC 606 involves precise chemical modification steps. Why does this matter to you? Because quality and consistency stem from how well these processes are controlled.

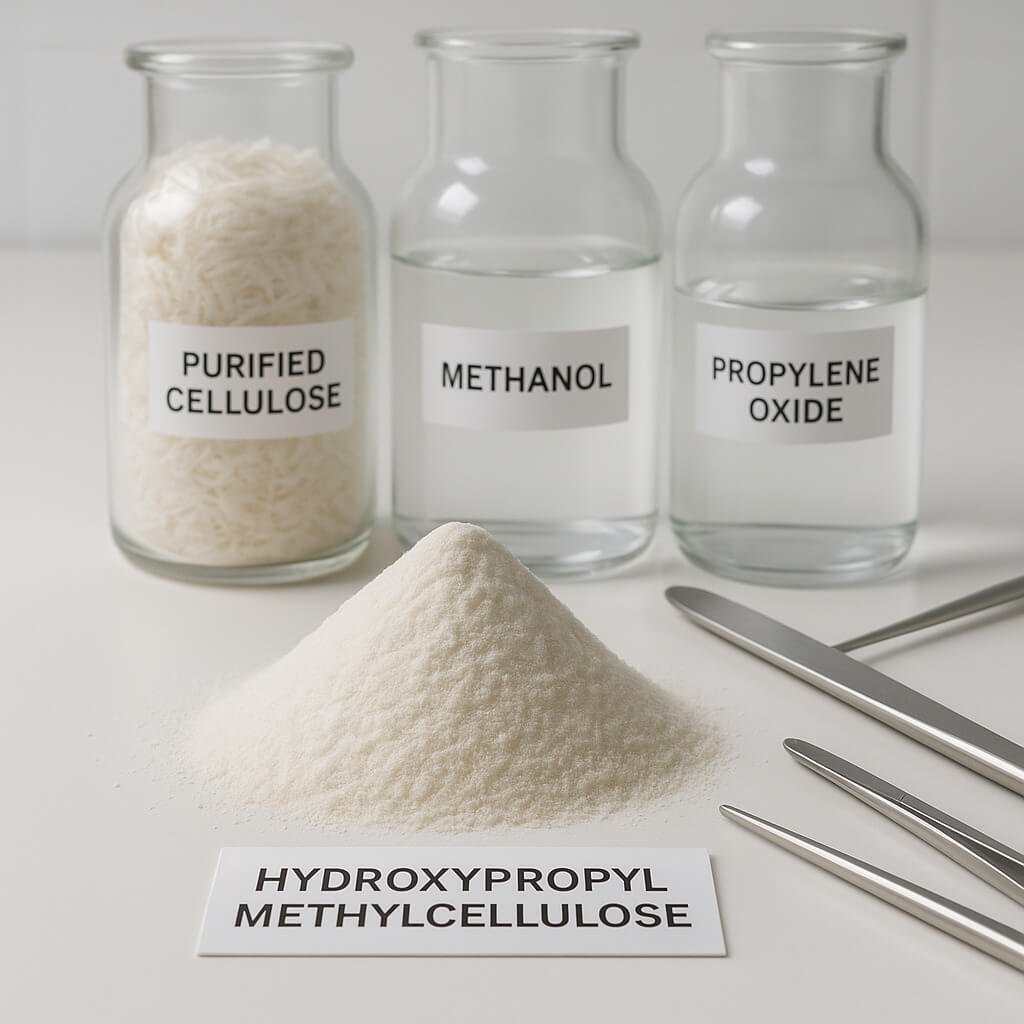

The journey begins with purified cellulose, usually derived from wood pulp or cotton linters. This substrate undergoes alkali treatment followed by methylation and hydroxypropylation reactions under strictly monitored conditions. These substitutions define HPMC 606’s unique viscosity and solubility profile by altering polymer chain structures.

Quality control during synthesis focuses on parameters like substitution degree, molecular weight, and residual impurities. Suppliers maintain stringent process controls to avoid batch-to-batch variability. For example, the alkali concentration must be carefully titrated; otherwise, polymer degradation may lower performance drastically.

Once synthesized, the polymer is dried into powder form or granules for shipment. Proper drying is key to preserving solubility. Some producers apply milling to achieve uniform particle sizes that ease formula incorporation.

One challenge manufacturers often face is balancing functional properties with cost-effectiveness. Higher substitution levels increase performance but escalate costs. Thus, suppliers and buyers negotiate specifications to meet both technical needs and budgets.

| خطوة التصنيع | غاية | تحدي |

|---|---|---|

| Cellulose purification | Raw material preparation | Ensuring raw material consistency |

| Alkali treatment | Activates cellulose chains | Maintaining ideal chemical balance |

| Methylation | Introduces methyl groups | Controlling substitution rates |

| هيدروكسي بروبيلاتيون | Adds hydroxypropyl groups | Avoiding over-modification |

| التجفيف والطحن | Produces finished product form | Preserving solubility and uniformity |

As a buyer, knowing these steps helps you engage with suppliers on technical grounds and ensures you get a product meeting your exact formulation requirements.

5. What Are the Key Applications of HPMC 606 in Industry?

HPMC 606 finds broad industrial use due to its functional versatility. Think about this: Its role varies significantly between construction, pharmaceutical, and food sectors, each depending on unique polymer properties.

In construction, HPMC 606 thickens and stabilizes mortar mixes, improving workability while reducing cracking and shrinkage. One ready-mix supplier reported a 15% increase in open time with its use, giving workers extra flexibility on site. Another benefit is improved water retention, important for curing processes.

Pharmaceutical formulators use HPMC 606 as a binder in tablets and as a matrix-forming agent for controlled-release medicines. Uniform coating achieved through HPMC 606 helps control drug release rates. Case examples include cardiovascular and pain relief drugs that rely on this polymer’s film-forming capacity.

The food industry applies HPMC 606 to improve texture and consistency in sauces, dressings, and low-fat products. Its ability to stabilize emulsions and prevent ingredient separation ensures product quality over shelf life. A manufacturer of salad dressings noted a 12% reduction in phase separation after switching to HPMC 606.

| صناعة | طلب | تأثير |

|---|---|---|

| بناء | Mortar thickening and water retention | Better workability and durability |

| المستحضرات الصيدلانية | Tablet binding and coating | إطلاق المخدرات الخاضع للرقابة |

| طعام | Emulsion stabilization | Extended shelf life and texture uniformity |

Heads up: Selecting the right grade and concentration of HPMC 606 is vital to maximize its benefits in each sector.

6. How Should HPMC 606 Be Stored and Handled?

Proper storage and handling of HPMC 606 directly affect its functionality in formulations. Pay attention here: Inadequate conditions can degrade the polymer, leading to poor performance and increased costs.

Recommended storage involves cool, dry environments shielded from moisture and contaminants. Excess humidity causes clumping or premature hydration, which compromises solubility. It is ideal to maintain temperatures below 30°C with relative humidity under 60%.

Handling precautions include using sealed containers or bulk silos with dust control measures. The polymer’s fine powder form poses inhalation risks and requires appropriate protective gear during loading or mixing. Some factories use automated feeding systems to minimize exposure.

Shelf life typically ranges from 12 to 24 months depending on packaging and storage conditions. Suppliers provide specific data sheets outlining stability under different scenarios.

A case from a chemical distributor showed a 30% increase in customer complaints due to poor storage practices causing polymer lumps. After implementing controlled storage and training, complaints dropped significantly.

| Storage Condition | الممارسة الموصى بها | سبب |

|---|---|---|

| درجة حرارة | Keep below 30°C | Maintain polymer stability |

| رطوبة | Below 60% relative humidity | Prevent clumping and moisture uptake |

| التعبئة والتغليف | Use sealed and dust-tight units | Protect from contamination |

| Handling | Use PPE and dust extraction | Protect worker health |

Let me emphasize: following these guidelines saves money and ensures product reliability in your processes.

7. What Are Common Challenges When Using HPMC 606?

HPMC 606 performs well when formulations and processes are optimized, but here’s the catch: challenges exist that can hinder results if overlooked.

Compatibility issues arise particularly with certain plasticizers, surfactants, or highly alkaline substances that may reduce viscosity or cause precipitation. Understanding ingredient interactions is essential to prevent formulation failure.

Processing challenges include controlling dispersion during mixing. HPMC 606 can form lumps if added too quickly to water or if mixing speeds are insufficient. This leads to uneven viscosity and inconsistent batch quality.

Another problem sometimes seen is variability in raw material batches causing shifts in polymer performance. This can lead to color changes, viscosity fluctuations, or settling of solids in product lines.

To tackle these obstacles, manufacturers rely on thorough preformulation testing and precise process controls. Adjusting addition rates, using appropriate dispersing agents, or replacing incompatible ingredients are common solutions.

| تحدي | سبب | استراتيجية التخفيف |

|---|---|---|

| Compatibility problems | Reactivity with additives | Ingredient compatibility testing |

| Dispersion difficulties | Improper mixing technique | Optimized addition timing and mixers |

| Batch variability | Raw material inconsistencies | Supplier quality assurance programs |

Keep this in mind: addressing these challenges early prevents costly production interruptions and returns.

8. How Is Quality of HPMC 606 Tested and Ensured?

Ensuring quality is a priority for all manufacturers using HPMC 606. وهنا السبب وراء أهمية ذلك: poor polymer quality undermines product performance and damages reputation.

Standard testing parameters include viscosity measurement using rotor viscometers, substitution degree by chemical analysis, moisture content, and microbial limits. Each ensures the polymer meets strict specifications.

Industry certifications such as ISO 9001 or FDA approval add another layer of assurance. They confirm the polymer’s suitability for specific sectors like pharma or food.

Quality can be checked both in labs and on the manufacturing floor. Routine in-process testing ensures consistency, while laboratory methods provide comprehensive profiles.

A pharmaceutical firm reported a decrease in batch failures after switching to a supplier with rigorous quality controls and analytical documentation.

| معلمة الجودة | طريقة الاختبار | أهمية الصناعة |

|---|---|---|

| اللزوجة | مقياس اللزوجة الدوراني | Determines polymer performance |

| Moisture | Karl Fischer titration | Ensures storage stability |

| درجة الاستبدال | Chemical assay | Confirms polymer functionality |

| الحدود الميكروبية | Microbiological culture testing | Crucial for pharma and food |

Here’s a quick thought: working with transparent suppliers providing full test data helps maintain consistent formulation outcomes.

9. Can HPMC 606 Be Customized for Specific Industrial Needs?

Customization options exist for HPMC 606 to better fit unique application demands. Now here’s the exciting part: by tweaking polymer characteristics or blending additives, formulators can unlock tailored performance profiles.

Modifications might include adjusting viscosity grade, particle size, or adding functional groups to improve water retention or film properties. Suppliers often provide technical support for these adaptations.

Case in point: a manufacturer of high-performance coatings asked for a finer particle size to improve suspension stability; after customization, their product exhibit better shelf life and application properties. Another pharma user required a lower viscosity grade to enable faster tablet disintegration; their supplier reformulated successfully. Food processors requested combinations of HPMC 606 with emulsifiers to boost texture and mouthfeel, addressing consumer preferences.

Custom formulations come at a cost premium but enhance competitiveness by offering exactly what an industrial process demands.

| جانب التخصيص | غاية | مثال للتطبيق |

|---|---|---|

| Viscosity grade | Control flow properties | Faster tablet disintegration |

| حجم الجسيمات | Improve dispersion and suspension | Stable coating suspensions |

| Functional additives | Enhance water retention or film | Moisture-proof food packaging |

Don’t overlook this: evaluating your needs can guide you on whether standard or customized HPMC 606 delivers better ROI.

10. What Are Emerging Trends Affecting the Use of HPMC 606?

The industrial landscape shifts continuously, affecting polymer demand and performance expectations. Let me cut to the chase: environmental and sustainability concerns are key drivers influencing HPMC 606’s future use.

Industries increasingly seek bio-based, biodegradable polymers. Since HPMC 606 derives from natural cellulose and is biodegradable, it fits well within green initiatives. The push for “clean label” and reduced chemical additives increases its appeal in food and pharma sectors.

Technological advances in polymer synthesis and processing also open new doors. For example, nano-engineered HPMC derivatives with enhanced film strength or controlled-release capabilities are under development, promising superior product functionalities.

Regulatory changes worldwide prompt manufacturers to seek polymers with clear safety profiles and traceability. HPMC 606 scores well here but must keep pace with evolving documentation standards.

| اتجاه | تأثير | Industry Response |

|---|---|---|

| الاستدامة | Demand for biodegradable polymers | Increased HPMC 606 sourcing |

| Advanced polymer tech | New functional derivatives | Development of nano-modified grades |

| Regulatory tightening | Stricter safety and traceability | Enhanced supplier documentation |

Think about this: staying informed on these trends is critical for industrial buyers aiming to future-proof their formulations while meeting customer expectations.

التعليمات

س1: What is HPMC 606?

HPMC 606 is a modified cellulose polymer widely used in industrial formulations for thickening, binding, and stabilizing products across sectors like construction, pharmaceuticals, and food.

س2: How does HPMC 606 improve industrial formulations?

It regulates viscosity, controls water retention, and maintains uniformity, enhancing product durability, consistency, and performance in varied applications.

س3: Which industries use HPMC 606 the most?

Construction, pharmaceutical, and food packaging industries primarily use HPMC 606 due to its adaptable properties suitable for multiple formulation needs.

س4: What storage conditions are ideal for HPMC 606?

Cool, dry storage conditions protected from moisture and contaminants optimize polymer stability and extend shelf life.

س5: How can I identify quality HPMC 606 products?

Look for certifications, consistent viscosity, purity standards, and detailed technical documentation from suppliers to ensure reliable quality.