When purchasing Hydroxypropyl Methylcellulose (HPMC) for industrial applications, one of the most important factors to consider is its performance and how different grades compare to alternatives. Is HPMC K100M/K15M/K4M equivalent to Rutocelheadcel? This is a crucial question for professionals in sectors like construction, pharmaceuticals, and food production, where precise performance is key. In this article, we will compare HPMC K100M/K15M/K4M to Rutocelheadcel, exploring their applications, differences, and how they stack up in terms of cost-effectiveness, performance, and suitability for various industries.

1. What Is HPMC K100M/K15M/K4M?

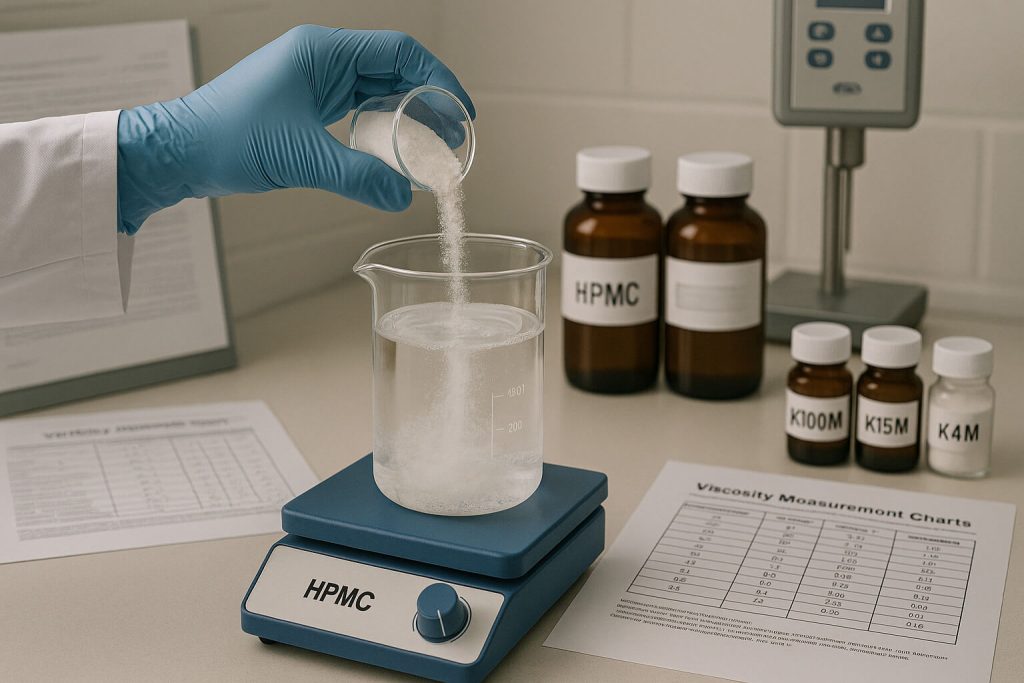

What’s the real story here? HPMC K100M, K15M, and K4M are specific grades of Hydroxypropyl Methylcellulose, a water-soluble polymer widely used in various industries. These grades differ primarily in their viscosity, which determines their performance in applications ranging from construction to pharmaceuticals.

HPMC is primarily used as a thickening agent, emulsifier, and binder. The K100M grade, with its higher viscosity, is often employed in demanding applications like thick adhesives and high-viscosity pharmaceutical formulations. The K15M and K4M grades, with slightly lower viscosities, are more suitable for lighter applications such as tile adhesives or food products.

These variations make HPMC a versatile compound in both industrial and consumer products. Whether you’re involved in construction materials, drug formulations, or food production, understanding the nuances of HPMC grades is vital. But here’s the kicker: the right choice depends not just on viscosity but also on the specific properties you need, such as solubility, film formation, and moisture retention.

HPMC K100M/K15M/K4M has been adopted in countless applications across industries. In construction, it’s used in mortars and plasters to enhance workability. In pharmaceuticals, it’s a critical component of tablet coatings and drug release. It plays a significant role in food manufacturing, where it contributes to texture and consistency.

Table 1: Comparison of HPMC K100M, K15M, and K4M Grades

| درجة | اللزوجة | التطبيقات الشائعة | الخصائص الرئيسية |

|---|---|---|---|

| K100M | عالي | Pharmaceuticals, Adhesives | High viscosity, strong film-forming properties |

| K15M | واسطة | Tile Adhesives, Mortars | Balanced viscosity, moderate workability |

| K4M | قليل | Food Industry, Coatings | Low viscosity, excellent solubility |

2. What Are the Uses of HPMC K100M/K15M/K4M?

هل أنت مستعد للجزء الجيد؟ Let’s dive into the various applications of HPMC K100M/K15M/K4M. As we mentioned earlier, HPMC is widely used across multiple industries, and its different grades cater to specific needs. Each of these grades offers unique advantages depending on the intended application.

في صناعة البناء, HPMC K100M/K15M/K4M is a critical ingredient in the production of dry mortar, tile adhesives, and joint fillers. These materials benefit from HPMC’s excellent water retention, which allows for better bonding and extended working time. In المستحضرات الصيدلانية, HPMC is primarily used in tablet formulations where its viscosity helps control the release rate of active ingredients. This makes it ideal for controlled-release formulations in drugs.

في صناعة الأغذية, HPMC plays a key role as a stabilizer, emulsifier, and thickening agent. It helps improve the texture of food products, such as plant-based beverages, dairy substitutes, and sauces, by increasing viscosity without altering flavor or color. The K4M grade, in particular, is popular in food products due to its low viscosity and excellent solubility.

What’s the real story? The versatility of HPMC makes it an indispensable ingredient in diverse applications. It’s critical to choose the right grade based on your industry needs, whether you need a high-viscosity agent for pharmaceutical use or a low-viscosity option for food products.

Table 2: Applications of HPMC K100M, K15M, and K4M

| صناعة | طلب | Recommended Grade |

|---|---|---|

| بناء | Mortar, Tile Adhesive | K100M, K15M |

| المستحضرات الصيدلانية | Drug Formulations, Coatings | K100M |

| إنتاج الغذاء | Beverages, Sauces, Dairy | K4M |

3. What Is Rutocelheadcel, and How Is It Used?

This is where it gets interesting… Rutocelheadcel is another cellulose derivative that competes with HPMC in various industrial applications. Like HPMC, Rutocelheadcel is used primarily as a thickening, stabilizing, and film-forming agent. However, there are key differences that influence which product is ideal for specific applications.

Rutocelheadcel is used in the construction industry in a similar way to HPMC, enhancing the workability and adhesion of dry mixes. It is also used in pharmaceuticals, particularly in tablet formulations, where it serves as a binder and helps in controlling the release of active ingredients. But what makes Rutocelheadcel stand out? It has a unique composition that offers slightly different rheological properties compared to HPMC, making it more suitable for certain formulations.

ولكن هنا تكمن المشكلة: Rutocelheadcel can sometimes offer a more cost-effective solution compared to HPMC, especially in applications where high viscosity is not as crucial. However, its performance in specialized applications, such as in highly viscous pharmaceutical formulations, may not match that of the K100M grade.

Table 3: Comparison of Rutocelheadcel and HPMC

| ملكية | Rutocelheadcel | HPMC K100M | HPMC K15M | HPMC K4M |

|---|---|---|---|---|

| اللزوجة | Moderate to High | عالي | واسطة | قليل |

| Common Use | المستحضرات الصيدلانية والبناء | Pharmaceuticals, Food | Mortar, Tile Adhesive | Food, Beverages |

| يكلف | أدنى | أعلى | معتدل | أدنى |

4. Is HPMC K100M/K15M/K4M Equivalent to Rutocelheadcel?

So, how do they compare? The answer depends on your specific needs. While HPMC K100M, K15M, and K4M are similar to Rutocelheadcel in many ways, they each have distinct properties that make them better suited for particular applications. For instance, the high viscosity of HPMC K100M makes it a superior choice for pharmaceutical formulations, especially where controlled-release of the active ingredient is required.

In comparison, Rutocelheadcel offers more versatility in certain cost-sensitive projects where high viscosity is not essential. However, what’s the real story is that when precise performance is required—such as in the construction of high-quality adhesives or in specific pharmaceutical products—HPMC K100M/K15M/K4M will often outperform Rutocelheadcel.

ولكن هنا تكمن المشكلة: the choice ultimately boils down to your application requirements and budget. If you’re looking for a cost-effective option without sacrificing too much performance, Rutocelheadcel could be the right choice. But for industries where performance and quality cannot be compromised, HPMC is the go-to.

Table 4: Performance Comparison of HPMC and Rutocelheadcel

| طلب | HPMC K100M/K15M/K4M | Rutocelheadcel |

|---|---|---|

| المستحضرات الصيدلانية | Best for controlled release formulations | Suitable for binding, not controlled release |

| بناء | Excellent for dry mixes, tile adhesives | Comparable, but less consistent viscosity |

| إنتاج الغذاء | Best for texture and emulsification | Suitable for some food products |

5. How Does HPMC K100M/K15M/K4M Perform in Construction Materials?

هل أنت مستعد للجزء الجيد؟ HPMC plays a crucial role in construction materials, especially in dry mixes like cement, tile adhesives, and plasters. The primary function of HPMC in these products is to improve workability, water retention, and adhesion. This makes applying products like mortar and adhesives much easier, especially in high-demand applications.

HPMC enhances the performance of construction materials by providing superior water retention. This means the materials stay workable longer, giving contractors more time to apply and adjust them. It also helps to achieve better bonding between surfaces, which is crucial for the long-term durability of buildings and structures. In fact, what’s the real story here is that without HPMC, the quality of construction materials could suffer, leading to issues such as cracks or poor adhesion.

ولكن هنا تكمن المشكلة: using the right grade of HPMC is critical. K100M, with its high viscosity, is ideal for more demanding applications, while K15M and K4M are better suited for lighter, everyday applications.

Table 5: Role of HPMC in Construction Materials

| Material Type | دور HPMC | Recommended Grade |

|---|---|---|

| هاون | Improves workability, water retention | K100M, K15M |

| مواد لاصقة للبلاط | Enhances bonding strength, extends working time | K100M, K15M |

| جص | Ensures consistency, prevents cracking | K4M, K15M |

6. How Does HPMC K100M/K15M/K4M Affect Pharmaceutical Formulations?

This is where it gets interesting… In the pharmaceutical industry, Hydroxypropyl Methylcellulose (HPMC) is a crucial ingredient for various applications, particularly in tablet formulations. One of the main benefits of HPMC is its ability to control the release of active ingredients, providing consistent dosing over time.

The K100M grade of HPMC, with its high viscosity, is essential for controlled-release formulations. It allows for the gradual release of the active pharmaceutical ingredient (API), making it a go-to choice for drugs that need to be delivered over an extended period. This feature is critical for medications used in chronic conditions, where maintaining a steady concentration of the drug in the bloodstream is necessary.

ولكن هنا تكمن المشكلة: HPMC’s role doesn’t stop at drug release. It also helps improve the stability and shelf life of pharmaceutical products. The ability to maintain consistent viscosity ensures that tablets and capsules maintain their integrity, even under varying storage conditions.

On the other hand, the K15M and K4M grades, which have lower viscosities, are used in formulations that don’t require controlled release. These grades are commonly used in conventional tablets, capsules, and suspensions, where their role is to act as a binder and to enhance the consistency of the mixture.

HPMC is also widely used in طلاءات الأفلام for tablets. These coatings provide protection against moisture and light, which can degrade sensitive drugs. This protective layer is particularly crucial for pharmaceuticals that need to be stored for long periods.

Table 6: Applications of HPMC in Pharmaceutical Formulations

| طلب | Grade Used | الوظيفة الرئيسية |

|---|---|---|

| Controlled-Release Formulations | K100M | Gradual release of active ingredients |

| Tablet Binders | K15M, K4M | Enhances consistency, prevents crumbling |

| طلاءات الأفلام | K100M, K15M | Protects drugs from moisture, light |

| التعليق | K4M | Stabilizes liquid formulations |

7. What Are the Benefits of Using HPMC in Food Production?

ما هي القصة الحقيقية؟ HPMC has proven itself as a versatile additive in the food industry, offering a range of benefits that improve the quality and texture of food products. It is widely used in the production of various food items such as plant-based dairy substitutes, beverages, sauces, and dressings.

HPMC’s primary function in food production is as a عامل تكثيف, but it also acts as an emulsifier and stabilizer. For example, in plant-based beverages and dairy alternatives, HPMC helps to prevent separation by stabilizing the mixture. This allows producers to create uniform products that maintain their texture and quality over time.

Another critical role of HPMC in food production is its ability to improve shelf life. By enhancing the viscosity and creating a stable, consistent texture, HPMC helps prevent ingredients from separating or degrading, which is particularly important for long-lasting packaged foods.

ولكن هنا تكمن المشكلة: HPMC also has the ability to reduce fat content in certain products. In reduced-fat formulations, it mimics the mouthfeel and texture of full-fat products, helping consumers enjoy the experience of full-fat foods while reducing their caloric intake.

The K4M grade of HPMC is particularly beneficial for the food industry due to its low viscosity and excellent solubility. It is commonly used in beverages, sauces, and low-calorie products where smooth texture and easy mixing are essential.

Table 7: Role of HPMC in Food Production

| Food Product Type | Grade Used | الوظيفة الرئيسية |

|---|---|---|

| Plant-Based Beverages | K4M | Stabilizes emulsions, prevents separation |

| Dairy Substitutes | K4M | Enhances texture, mimics full-fat experience |

| الصلصات والتتبيلات | K4M | Thickens and stabilizes |

| Low-Calorie Products | K4M | Reduces fat content, maintains texture |

8. How Do HPMC K100M/K15M/K4M and Rutocelheadcel Compare in Cost-Effectiveness?

This is where the decision gets tricky… When selecting between HPMC K100M/K15M/K4M and Rutocelheadcel, cost-effectiveness is always a key factor. While both substances serve similar functions, there are notable differences in their cost structure and performance.

HPMC is generally considered more expensive than Rutocelheadcel, especially for high-viscosity grades like K100M. However, what’s the real story here is that the added cost of HPMC is often justified by its superior performance in demanding applications, such as controlled-release pharmaceutical formulations and high-performance construction materials.

On the other hand, Rutocelheadcel can be a more cost-effective choice for applications that do not require the higher viscosity and specialized properties of HPMC. For example, in industries where only basic thickening or binding is needed, Rutocelheadcel can deliver satisfactory results at a lower cost.

ولكن هنا تكمن المشكلة: While Rutocelheadcel might be cheaper upfront, HPMC’s longer-lasting performance and ability to meet strict industry standards can result in lower overall costs in the long run. This is particularly true in pharmaceuticals, where precise drug release and stability are non-negotiable.

Table 8: Cost Comparison of HPMC and Rutocelheadcel

| Grade/Type | يكلف | حالة الاستخدام النموذجية | Performance Rating |

|---|---|---|---|

| HPMC K100M | عالي | تركيبات الإطلاق الخاضع للرقابة | عالي |

| HPMC K15M | معتدل | Tile adhesives, pharmaceuticals | معتدل |

| HPMC K4M | قليل | Food production, low viscosity uses | معتدل |

| Rutocelheadcel | أدنى | General applications, adhesives | معتدل |

9. What Are the Advantages of Using HPMC in Various Industries?

Let’s break this down… HPMC has a broad range of applications across different industries, making it a versatile and valuable ingredient. Whether it’s enhancing the quality of pharmaceuticals, improving the performance of construction materials, or providing texture to food products, HPMC offers numerous benefits.

في المستحضرات الصيدلانية, the ability to control drug release is the primary advantage of HPMC. This ensures that medications are effective over longer periods and reduces the need for frequent dosing. Additionally, HPMC’s stabilizing properties extend the shelf life of drugs.

في بناء, HPMC’s role in enhancing the workability, water retention, and adhesion of materials makes it indispensable in dry mixes, tile adhesives, and mortars. This results in better performance, reduced waste, and more efficient construction processes.

For the صناعة الأغذية, HPMC offers improved texture and mouthfeel without altering the flavor profile of products. Its ability to mimic the texture of fat makes it especially valuable in low-calorie and plant-based products.

ولكن هنا تكمن المشكلة: The adaptability of HPMC across various industries is a major reason why it remains a top choice for manufacturers. It enhances the performance of products and reduces production costs in the long run.

Table 9: Advantages of HPMC Across Industries

| صناعة | Key Benefit | الاستخدام النموذجي |

|---|---|---|

| المستحضرات الصيدلانية | Controlled drug release, stability | Tablets, capsules |

| بناء | Workability, water retention, adhesion | Mortar, tile adhesives |

| إنتاج الغذاء | Texture enhancement, stabilizer | Beverages, dairy substitutes |

10. How Can You Choose Between HPMC K100M/K15M/K4M and Rutocelheadcel?

What’s the takeaway here? When deciding between HPMC and Rutocelheadcel, it’s essential to evaluate your specific application needs, cost constraints, and performance expectations. HPMC’s higher viscosity grades, such as K100M, are ideal for more demanding uses, like pharmaceuticals and high-quality construction materials, where performance cannot be compromised.

Rutocelheadcel, while more affordable, is best suited for applications that do not require high viscosity or specialized properties. It can be a great choice for general-purpose applications like standard adhesives, certain food products, and basic construction uses.

ولكن هنا تكمن المشكلة: Ultimately, the choice comes down to balancing performance and budget. If you need precise control and long-term reliability, HPMC is the way to go. However, if cost is a major factor and performance requirements are more general, Rutocelheadcel can serve as an economical alternative.

Table 10: Choosing Between HPMC and Rutocelheadcel

| عامل | HPMC K100M/K15M/K4M | Rutocelheadcel |

|---|---|---|

| نوع التطبيق | High-performance needs | General-purpose uses |

| Performance Needs | Superior viscosity control | Moderate viscosity control |

| Budget Consideration | تكلفة أعلى ولكن أداء أفضل | Lower cost, less specialized performance |

قسم الأسئلة الشائعة

س1: What is HPMC K100M/K15M/K4M?

HPMC K100M/K15M/K4M are different grades of Hydroxypropyl Methylcellulose, used primarily in pharmaceuticals, construction, and food production. They differ mainly in viscosity, with K100M being the highest.

س2: How does HPMC K100M/K15M/K4M work in construction materials?

HPMC enhances the workability, water retention, and adhesion of materials like mortar and tile adhesives, ensuring better performance and durability in construction projects.

س3: How does HPMC K100M/K15M/K4M compare to Rutocelheadcel?

HPMC and Rutocelheadcel are both cellulose derivatives, but HPMC generally offers better performance for specialized applications like pharmaceutical formulations and high-viscosity construction materials.

س4: What are the key benefits of using HPMC in pharmaceuticals?

HPMC controls the release of active ingredients, improves stability, and enhances the consistency of pharmaceutical products, making it essential for controlled-release formulations.

س5: How do I choose between HPMC and Rutocelheadcel for my industry?

Choosing between HPMC and Rutocelheadcel depends on your application’s viscosity needs, performance requirements, and budget. HPMC is better for specialized applications, while Rutocelheadcel is a more cost-effective choice for general uses.