Hydroxypropylmethylcellulose (HPMC) ist ein Cellulosederivat, das in verschiedenen Branchen, darunter der Pharmaindustrie, dem Baugewerbe und der Lebensmittelproduktion, eine entscheidende Rolle spielt. Seine Vielseitigkeit und seine einzigartigen Eigenschaften machen es unverzichtbar für Anwendungen, bei denen Konsistenz, Bindung und Stabilität entscheidend sind. Dieser Artikel untersucht die wichtigsten Eigenschaften von HPMC, seine branchenübergreifenden Anwendungen und die erheblichen Vorteile für Hersteller. Durch das Verständnis dieser Aspekte können Sie fundierte Entscheidungen über den Einsatz von HPMC in Ihren Formulierungen treffen.

1. Was ist Hydroxypropylmethylcellulose und warum ist sie wichtig?

Hydroxypropylmethylcellulose (HPMC) ist ein wasserlösliches, halbsynthetisches Polymer, das aus Cellulose, dem natürlichen Polymer pflanzlicher Zellwände, gewonnen wird. Es wird durch die Zugabe von Hydroxypropyl- und Methylgruppen modifiziert, die ihm seine einzigartigen Eigenschaften verleihen. Diese Modifikationen ermöglichen HPMC eine leichte Wasserlöslichkeit und Gelbildung, weshalb es in verschiedenen Branchen weit verbreitet ist.

Warum ist das wichtig? Aufgrund seiner Fähigkeit zur Gelbildung und seiner hervorragenden Löslichkeit wird HPMC häufig in Anwendungen eingesetzt, in denen ein stabiles, konsistentes Produkt benötigt wird. Im Bauwesen wird es verwendet, um die Verarbeitbarkeit von Trockenmischungen zu verbessern, während es in der Pharmaindustrie als Bindemittel und Wirkstoff zur kontrollierten Freisetzung von Tabletten eingesetzt wird. In der Lebensmittelproduktion fungiert es als Stabilisator, Emulgator und Verdickungsmittel und sorgt dafür, dass Produkte ihre gewünschte Textur und Konsistenz behalten.

Die Bedeutung von HPMC kann nicht hoch genug eingeschätzt werden. Es bietet einzigartige funktionale Vorteile, die es Herstellern ermöglichen, ihre Produkte auf eine Weise zu optimieren, die mit anderen Polymeren nicht möglich ist. Ob es darum geht, Fließfähigkeit und Haftung von Baumaterialien zu verbessern, die Freisetzung von Medikamenten im Körper zu steuern oder die Textur von Lebensmitteln zu verbessern – HPMC ist für die Bereitstellung hochwertiger Lösungen unverzichtbar.

| Industrie | Häufige Verwendung | Rolle von HPMC |

|---|---|---|

| Pharmazeutika | Bindemittel, Retardmittel | Konsistente, kontrollierte Arzneimittelabgabe |

| Konstruktion | Mörtel, Klebstoffe | Verbessert die Verarbeitbarkeit, Haftung und Wasserspeicherung |

| Essen | Emulgatoren, Stabilisatoren | Erhält die Textur und verhindert die Trennung |

2. Was sind die wichtigsten Eigenschaften von Hydroxypropylmethylcellulose?

Zu den wichtigsten Eigenschaften von HPMC, die es branchenübergreifend so nützlich machen, gehören seine Wasserlöslichkeit, seine Viskositätskontrolle, seine Gelbildungsfähigkeit und seine thermische Stabilität. Das Verständnis dieser Eigenschaften ist der Schlüssel zur Optimierung der Leistung von HPMC in verschiedenen Anwendungen.

Wasserlöslichkeit ist eine der wichtigsten Eigenschaften von HPMC. Sie ermöglicht dem Polymer, sich leicht in kaltem und heißem Wasser aufzulösen und eine gelartige Substanz zu bilden, deren Viskosität auf bestimmte Viskositäten eingestellt werden kann. Dies macht es äußerst vielseitig für Anwendungen von der Pharmazie bis zur Lebensmittelherstellung, wo die Löslichkeit entscheidend für die gewünschte Textur und Konsistenz ist.

Viskositätskontrolle ist eine weitere wichtige Eigenschaft von HPMC. Je nach Molekulargewicht und Konzentration kann HPMC Lösungen von flüssig bis hochviskos erzeugen. In der Pharmaindustrie ist dies wichtig, um sicherzustellen, dass Tabletten und Kapseln die richtige Konsistenz und Struktur behalten. In der Lebensmittelindustrie sorgt die Viskositätskontrolle dafür, dass Soßen, Suppen und andere Produkte die richtige Dicke haben, eine Trennung verhindern und das Mundgefühl erhalten bleibt.

Gelbildungsfähigkeit Ermöglicht den Einsatz von HPMC in Arzneimittelverabreichungssystemen mit kontrollierter Wirkstofffreisetzung, da es ein Gel bildet, das die Freisetzung von Wirkstoffen reguliert. Es ist auch in der Bauindustrie nützlich, wo HPMC Trockenmischungen zugesetzt wird, um die Verarbeitbarkeit und Haftung zu verbessern.

Schließlich, Thermische Stabilität stellt sicher, dass HPMC seine Funktionalität bei unterschiedlichen Temperaturen behält. Dies ist besonders wichtig in der Lebensmittel- und Bauindustrie, wo Materialien unterschiedlichen Umweltbedingungen ausgesetzt sind.

| Eigentum | Funktionalität | Anwendung |

|---|---|---|

| Wasserlöslichkeit | Leichte Auflösung in kaltem und heißem Wasser | Pharmazeutika, Lebensmittel, Bau |

| Viskositätskontrolle | Einstellbare Viskosität für unterschiedliche Anwendungen | Pharmazeutika, Lebensmittel, Klebstoffe |

| Gelbildungsfähigkeit | Erzeugt Gele für eine kontrollierte Freisetzung | Pharmazeutika, Bau |

| Thermische Stabilität | Behält die Funktionalität bei unterschiedlichen Temperaturen bei | Lebensmittel, Bau, Pharma |

3. Wie wird Hydroxypropylmethylcellulose in der Pharmaindustrie verwendet?

In der Pharmaindustrie wird HPMC vor allem als Bindemittel Und Mittel zur kontrollierten Freisetzung in Tablettenformulierungen. Die Binderfunktion ist wichtig, um sicherzustellen, dass die Wirkstoffe in Tabletten zusammengehalten werden, die Integrität der Tablette erhalten bleibt und verhindert wird, dass sie zerbröselt oder sich vorzeitig auflöst. Indem HPMC die Inhaltsstoffe gleichmäßig zusammenhält, verbessert es die Konsistenz der Tablette und trägt zu ihrer kontrollierten Auflösung bei.

Arzneimittelverabreichung mit kontrollierter Freisetzung ist eine weitere wichtige Anwendung für HPMC. Dabei wird HPMC verwendet, um die Freisetzungsrate des Medikaments im Körper zu kontrollieren und so eine anhaltende Freisetzung über einen längeren Zeitraum zu gewährleisten. Dies ist besonders vorteilhaft für Patienten, die über den Tag hinweg eine gleichbleibende therapeutische Medikamentendosis benötigen. Dadurch wird die Notwendigkeit häufiger Dosierungen reduziert und die Compliance der Patienten verbessert.

HPMC wird auch verwendet in pharmazeutische Gele Und WundpflegeprodukteSeine gelbildenden Eigenschaften ermöglichen den Einsatz als Matrix für die kontrollierte Freisetzung pharmazeutischer Wirkstoffe. Bei topischen Behandlungen trägt HPMC dazu bei, dass die Wirkstoffe effektiv in die Haut eindringen und gleichzeitig die Stabilität der Gelformulierung erhalten bleibt.

| Pharmazeutische Anwendung | Funktion | Nutzen |

|---|---|---|

| Bindemittel | Hält Wirkstoffe zusammen | Konsistenz, Integrität der Tabletten |

| Kontrollierte Freisetzung | Reguliert die Freisetzungsrate von Medikamenten | Verzögerte Freisetzung, Patienten-Compliance |

| Gele und Wundpflege | Matrix für Wirkstoffe | Kontrollierte Abgabe, Stabilität |

4. Welchen Nutzen hat Hydroxypropylmethylcellulose für die Lebensmittelindustrie?

In der Lebensmittelindustrie ist HPMC aufgrund seiner einzigartigen Eigenschaften eine unschätzbar wertvolle Zutat. Als Verdickungsmittel, trägt es dazu bei, die richtige Textur in Soßen, Suppen und Dressings zu erreichen. Durch die Erhöhung der Viskosität sorgt HPMC dafür, dass diese Produkte ihre Konsistenz behalten und sich während der Lagerung nicht trennen.

Emulgierung ist eine weitere wichtige Anwendung von HPMC in Lebensmitteln. Es hilft, Öl- und Wasserphasen in Schwebe zu halten und verhindert so deren Trennung. Dies ist besonders wichtig bei Produkten wie Mayonnaise, Eiscreme und Salatdressings, bei denen eine glatte, gleichmäßige Textur für die Zufriedenheit des Verbrauchers entscheidend ist.

HPMC wird auch verwendet als Stabilisator In verschiedenen Lebensmitteln trägt HPMC dazu bei, die Textur zu erhalten und Veränderungen während der Verarbeitung oder Lagerung zu verhindern. Beispielsweise kann HPMC bei glutenfreien oder pflanzlichen Lebensmitteln die Textur und Elastizität verbessern und diesen Produkten ein angenehmeres Mundgefühl und eine angenehmere Konsistenz verleihen.

Ein weiterer Vorteil von HPMC in der Lebensmittelproduktion ist seine Fähigkeit, herkömmliche Verdickungsmittel und Stabilisatoren zu ersetzen und bietet eine vegane und allergenfreie Alternative zu Zutaten wie Gelatine und Eiweiß.

| Lebensmittelanwendung | Funktion | Nutzen |

|---|---|---|

| Verdickungsmittel | Erhöht die Viskosität in Soßen, Suppen | Konsistenz, verhindert Trennung |

| Emulgator | Hält Öl und Wasser in Schwebe | Glatte Textur, gleichmäßige Konsistenz |

| Stabilisator | Behält die Textur während der Lagerung | Verhindert Veränderungen, verbessert die Haltbarkeit |

5. Wie wird Hydroxypropylmethylcellulose in der Bauindustrie eingesetzt?

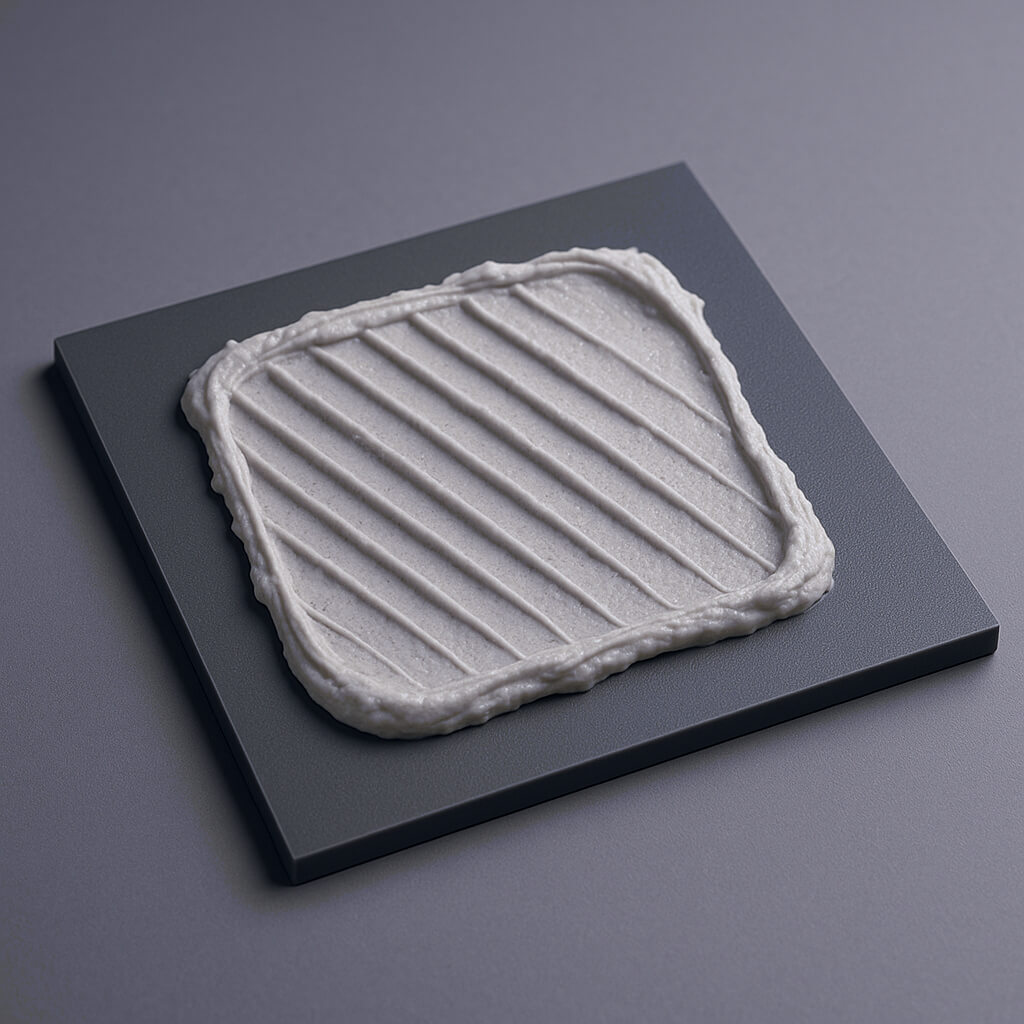

Im Bauwesen spielt HPMC eine bedeutende Rolle als Zusatzstoff In Trockenmörtel, Pflaster, Und Fliesenkleber. Seine Löslichkeits- und Viskositätskontrolleigenschaften Stellen Sie sicher, dass sich diese Materialien leicht mischen, verteilen und auftragen lassen, was die Verarbeitbarkeit verbessert. Ohne HPMC könnten diese Materialien zu dick werden und sich daher nur schwer gleichmäßig verteilen lassen, was sich negativ auf Haftung und Klebkraft auswirken könnte.

Wassereinlagerungen ist eine weitere wichtige Eigenschaft von HPMC im Bauwesen. Es hilft dem Mörtel oder Putz, Feuchtigkeit zu speichern, verhindert vorzeitiges Austrocknen und gewährleistet eine ordnungsgemäße Aushärtung. Dies ist besonders wichtig in trockenen Klimazonen oder bei Großprojekten, bei denen langfristige Konsistenz entscheidend ist.

HPMCs haftvermittelnde Eigenschaften sind beispielsweise für Fliesenkleber von Vorteil. Durch die verbesserte Haftung auf Oberflächen sorgt HPMC dafür, dass die Fliesen länger an ihrem Platz bleiben und sich mit der Zeit nicht mehr lösen oder verschieben. Dies ist sowohl aus ästhetischen als auch aus Sicherheitsgründen bei Bauprojekten von entscheidender Bedeutung.

| Bauantrag | Funktion | Nutzen |

|---|---|---|

| Trockenmörtel | Verbessert die Verarbeitbarkeit, verhindert Verklumpen | Einfaches Mischen und Verteilen |

| Pflaster | Behält die Feuchtigkeit, verhindert vorzeitiges Austrocknen | Sorgt für eine ordnungsgemäße Aushärtung |

| Fliesenkleber | Verbessert die Haftung | Langlebige Verbindung, Haltbarkeit |

6. Welche Umweltvorteile und Nachhaltigkeit bietet Hydroxypropylmethylcellulose?

In den letzten Jahren Nachhaltigkeit ist zu einem kritischen Anliegen in verschiedenen Branchen geworden, und HPMC bietet mehrere UmweltvorteileEiner der wichtigsten Vorteile ist, dass HPMC biologisch abbaubar, was bedeutet, dass es in der Umwelt auf natürliche Weise abgebaut wird, ohne schädliche Rückstände zu hinterlassen. Dies ist besonders wichtig in Branchen wie dem Baugewerbe und der Lebensmittelindustrie, in denen die Umweltauswirkungen zunehmend unter die Lupe genommen werden.

HPMCs umweltfreundliche Natur macht es zu einer attraktiven Alternative zu anderen synthetischen Polymeren, die nicht biologisch abbaubar sind und zur Umweltverschmutzung beitragen. Im BauDie Fähigkeit von HPMC, die Leistung ohne Zugabe schädlicher Chemikalien zu steigern, steht im Einklang mit der wachsenden Nachfrage nach nachhaltigen Baumaterialien.

In grünes BauenHPMC wird verwendet, um herkömmliche Zusatzstoffe in Produkten wie Mörtel und Klebstoffen zu ersetzen und trägt so zur Reduzierung des CO2-Fußabdrucks dieser Materialien bei. HPMC trägt auch zur nachhaltigen Lebensmittelproduktion bei, insbesondere wenn es als pflanzliche Alternative zu tierischen Inhaltsstoffen wie Gelatine verwendet wird.

| Umweltvorteile | Beschreibung | Anwendung |

|---|---|---|

| Biologische Abbaubarkeit | Zersetzt sich auf natürliche Weise ohne schädliche Rückstände | Bau, Lebensmittel |

| Umweltfreundlich | Nachhaltige Alternative zu synthetischen Polymeren | Ökologisches Bauen, nachhaltige Lebensmittelproduktion |

7. Wie kann Hydroxypropylmethylcellulose für bestimmte Anwendungen angepasst werden?

Einer der attraktivsten Aspekte von HPMC ist seine VielseitigkeitEs kann sein individuell um den spezifischen Anforderungen verschiedener Anwendungen gerecht zu werden. Hersteller können Viskosität, Auflösungsrate und Substitutionsgrad anpassen von HPMC basierend auf den Anforderungen des Endprodukts.

Beispielsweise in der Pharmaindustrie kundenspezifische HPMC-Typen Kann entwickelt werden, um die Freisetzungsrate eines Arzneimittels zu steuern. Dies ermöglicht Formulierungen mit verlängerter Freisetzung, die den Wirkstoff über einen längeren Zeitraum freisetzen. In Lebensmittelanwendungen kann HPMC modifiziert werden, um die perfekte Textur für pflanzliche Produkte zu gewährleisten und ein konsistentes Mundgefühl ähnlich wie bei herkömmlichen Produkten zu erzielen.

Anpassen der Substitutionsgrad ermöglicht es Herstellern, die funktionellen Eigenschaften von HPMC zu kontrollieren. Höhere Substitutionsgrade können die Löslichkeit erhöhen, während niedrigere Konzentrationen zu einer besseren Gelbildung führen können. Durch die individuelle Anpassung wird sichergestellt, dass HPMC in einer Vielzahl von Branchen, unabhängig von der Anwendung, optimale Leistung erbringt.

| Anpassungsaspekt | Funktion | Nutzen |

|---|---|---|

| Viskositätskontrolle | Passt die Dicke von Lösungen an | Maßgeschneiderte Leistung für verschiedene Branchen |

| Auflösungsrate | Steuert die Arzneimittelfreisetzung oder Emulgierungsrate | Verlängerte Freisetzung, konsistente Textur |

| Substitutionsgrad | Beeinflusst Löslichkeit und Gelbildung | Fein abgestimmte Eigenschaften für spezifische Anforderungen |

8. Welche Herausforderungen gibt es bei der Verwendung von Hydroxypropylmethylcellulose?

Obwohl HPMC ein unglaublich nützliches Polymer ist, gibt es auch Herausforderungen damit. Eines der häufigsten Probleme besteht darin, eine konsistente Auflösung zu erreichen. Wenn HPMC nicht richtig aufgelöst wird, kann es insbesondere bei der Produktion im großen Maßstab zu Verklumpungen oder einer ungleichmäßigen Textur kommen. Einhaltung des richtigen Wasser-Polymer-Verhältnisses und der richtigen Rührgeschwindigkeit ist für eine reibungslose Auflösung unerlässlich.

Eine weitere Herausforderung ist Temperaturempfindlichkeit. Während HPMC bei moderaten Temperaturen stabil ist, Übermäßige Hitze kann das Polymer zersetzen, wodurch seine Funktionalität beeinträchtigt wird. Es ist wichtig sicherzustellen, dass die Temperatur im optimalen Bereich bleibt, um die Eigenschaften des Polymers zu erhalten.

Probleme in der Lieferkette kann sich auch auf die Verfügbarkeit und die Kosten von HPMC auswirken. Abhängig von der Cellulosequelle und dem Grad der Modifikation, kann es zu Schwankungen bei Qualität und Preis kommen, die sich auf die Produktionskosten auswirken können.

| Herausforderung | Ursache | Lösung |

|---|---|---|

| Inkonsistente Auflösung | Falsches Verhältnis, Rührgeschwindigkeit | Stellen Sie sicher, dass die Mischung und das richtige Verhältnis richtig sind |

| Temperatursensitivität | Abbau bei hohen Temperaturen | Halten Sie den optimalen Temperaturbereich ein |

| Probleme in der Lieferkette | Schwankungen in Qualität oder Kosten | Quelle zuverlässig |

Lieferanten, Produktion optimieren |

9. Gibt es Alternativen zu Hydroxypropylmethylcellulose?

Obwohl HPMC weit verbreitet ist, bieten mehrere Alternativen ähnliche Eigenschaften. Methylcellulose (MC) ist eine solche Alternative, die häufig in der Lebensmittel- und Pharmaindustrie verwendet wird. MC hat viele Eigenschaften mit HPMC gemeinsam, neigt jedoch bei höheren Temperaturen zur Gelbildung und ist daher für bestimmte Anwendungen besser geeignet.

Carboxymethylcellulose (CMC) ist eine weitere Alternative, die für ihre Fähigkeit bekannt ist, die Viskosität in einer Vielzahl von Formulierungen zu kontrollieren. CMC wird häufig in der Lebensmittel- und Pharmaindustrie eingesetzt, bietet jedoch nicht das gleiche Maß an Gelbildung wie HPMC.

Trotz dieser Alternativen HPMC bleibt die bevorzugte Wahl aufgrund seiner einzigartigen Kombination von Eigenschaften, einschließlich seiner Wasserlöslichkeit, Gelbildungsfähigkeit, Und Branchenübergreifende Vielseitigkeit. Es ist besonders nützlich in Arzneimittelsystemen mit kontrollierter Freisetzung, Baumaterialien und Lebensmittelformulierungen.

| Alternative | Hauptmerkmale | Anwendungen |

|---|---|---|

| Methylcellulose | Gelbildung bei höheren Temperaturen | Lebensmittel, Pharmazeutika |

| Carboxymethylcellulose | Viskositätskontrolle | Lebensmittel, Pharmazeutika |

| HPMC | Wasserlöslichkeit, gelbildend | Pharma, Bau, Lebensmittel |

Abschluss

Zusammenfassend lässt sich sagen, dass Hydroxypropylmethylcellulose (HPMC) ein unglaublich vielseitiges Polymer ist, das in einer Vielzahl von Branchen eine wichtige Rolle spielt. Von der Pharmaindustrie über die Lebensmittelindustrie bis hin zum Bauwesen machen die einzigartigen Eigenschaften von HPMC, darunter Wasserlöslichkeit, Viskositätskontrolle und Gelbildungsfähigkeit, es unverzichtbar. Seine Anpassungsmöglichkeiten ermöglichen eine gezielte Leistung für spezifische Anwendungen, während seine biologische Abbaubarkeit und Umweltfreundlichkeit es zu einer nachhaltigen Wahl machen. Durch das Verständnis der wichtigsten Eigenschaften und Anwendungen von HPMC können Branchen sein volles Potenzial für hochwertige, konsistente Produkte nutzen.

Häufig gestellte Fragen

Frage 1: Was ist Hydroxypropylmethylcellulose (HPMC)?

HPMC ist ein aus Zellulose gewonnenes Polymer, das als Bindemittel, Emulgator und Stabilisator in verschiedenen Branchen wie der Pharma-, Lebensmittel- und Bauindustrie verwendet wird.

Q2: Welchen Nutzen hat HPMC für die Pharmaindustrie?

HPMC dient in Tabletten als Bindemittel und Mittel zur kontrollierten Freisetzung, sorgt für eine gleichmäßige Wirkstofffreisetzung und verbessert die Integrität der Tablette.

Drittes Quartal: Welche Rolle spielt HPMC in der Lebensmittelindustrie?

In Lebensmitteln fungiert HPMC als Verdickungsmittel, Emulgator und Stabilisator, verbessert Textur und Konsistenz und verhindert die Trennung in Produkten wie Soßen und Dressings.

Viertes Quartal: Wie verbessert HPMC Baumaterialien?

HPMC verbessert die Verarbeitbarkeit, Haftung und Wasserspeicherung in Trockenmörteln, Putzen und Klebstoffen und sorgt so für eine einfache Handhabung und starke, dauerhafte Verbindungen.

Frage 5: Welche Vorteile bietet HPMC für die Umwelt?

HPMC ist biologisch abbaubar und umweltfreundlich und stellt somit eine nachhaltige Alternative zu synthetischen Polymeren im Bau- und Lebensmittelbereich dar.