The manufacturing industry constantly seeks innovative materials to enhance product quality and performance. Hydroxypropyl methylcellulose (HPMC) has emerged as a versatile additive that addresses numerous challenges across various sectors. This article examines how HPMC can significantly improve your product performance, from its fundamental properties to practical applications. Whether you work in construction, pharmaceuticals, food production, or personal care, understanding HPMC’s capabilities can provide your business with a competitive edge. By exploring the technical aspects, cost benefits, and implementation strategies of HPMC, you’ll gain valuable insights into optimizing your manufacturing processes and delivering superior products to your customers.

1. What Is HPMC And Why Is It Important For Manufacturing?

Hydroxypropyl methylcellulose (HPMC) is a semi-synthetic, non-ionic cellulose ether derived from natural cellulose through chemical modification. This versatile polymer consists of cellulose backbones with hydroxypropyl and methyl substitution groups, creating a compound with unique physicochemical properties.

Here’s the truth: HPMC has become indispensable across multiple industries due to its exceptional functionality and versatility.

The development of HPMC dates back to the 1960s, when researchers sought alternatives to traditional thickeners and binders. Today, HPMC is produced on an industrial scale with stringent quality control measures to meet diverse application requirements.

What makes HPMC particularly valuable in manufacturing settings is its multifunctional nature. It serves as a thickener, binder, film-former, water-retention agent, and stabilizer—all in a single ingredient. This multifunctionality allows manufacturers to simplify formulations while achieving multiple performance benefits.

| Wichtige Eigenschaften von HPMC | Manufacturing Benefits |

|---|---|

| Wasserlöslichkeit | Easy incorporation into water-based systems |

| Thermische Gelierung | Temperature-responsive performance |

| Filmbildende Fähigkeit | Creates protective barriers and coatings |

| Binding capacity | Enhances structural integrity |

| Oberflächenaktivität | Stabilizes emulsions and suspensions |

The adoption of HPMC spans numerous industries, each leveraging specific aspects of its performance profile. In construction, HPMC improves workability and water retention in mortars and cement-based products. Pharmaceutical manufacturers utilize it for controlled drug release and tablet coating. Food producers rely on HPMC for texture modification and stability enhancement. Personal care formulators incorporate it for its thickening and stabilizing properties.

2. What Technical Properties Make HPMC Stand Out From Other Additives?

The exceptional performance of HPMC in various applications stems from its unique technical properties that distinguish it from other common additives. Understanding these properties helps manufacturers leverage HPMC’s full potential in their specific applications.

Want to know something interesting? HPMC’s viscosity behavior sets it apart from most other thickening agents on the market.

When dispersed in water, HPMC forms solutions with predictable and controllable viscosity profiles. Unlike many natural gums that exhibit variable performance, HPMC provides consistent thickening across batches. Manufacturers can select from a wide range of viscosity grades (from 3 to 200,000 mPa·s) to achieve precise flow characteristics in their products.

One of HPMC’s most distinctive features is its thermal gelation property. While most hydrocolloids lose viscosity when heated, HPMC solutions exhibit inverse solubility—they form reversible gels at elevated temperatures.

| Temperaturbereich | HPMC-Verhalten | Anwendungsvorteile |

|---|---|---|

| Below 20°C | Readily dissolves | Easy incorporation during cold processing |

| 20-50°C | Stable solution | Consistent performance during standard processing |

| 50-70°C | Begins gelation | Controlled release and stability during heating |

| Über 70°C | Forms reversible gel | Heat-triggered functionality |

The water retention capability of HPMC provides significant advantages in formulations where moisture control is critical. In cement-based products, for instance, HPMC can retain water up to 70 times its weight, preventing premature drying and ensuring proper hydration.

HPMC forms transparent, flexible films with excellent oxygen and grease barrier properties. These films are resistant to oils and organic solvents while remaining water-soluble. Such characteristics make HPMC ideal for protective coatings, encapsulation, and controlled-release applications.

Another standout feature is HPMC’s stability across a wide pH range (2-12). Unlike many natural and synthetic polymers that degrade or lose functionality in acidic or alkaline conditions, HPMC maintains its performance characteristics. This pH stability enables its use in diverse formulations without compatibility concerns.

3. How Does HPMC Enhance Product Quality In Different Industries?

HPMC delivers specific performance benefits across various industries, each leveraging its unique properties to enhance product quality and functionality.

Lassen Sie mich das klarstellen: The versatility of HPMC makes it a valuable additive across multiple manufacturing sectors, with each industry benefiting from specific performance enhancements.

In the construction industry, HPMC significantly improves the workability and water retention of cement-based products. When added to mortars, renders, and tile adhesives at concentrations of 0.2-0.5%, HPMC extends open time by up to 300% compared to unmodified formulations. This extended working time allows for proper application and finishing, particularly in challenging conditions like high temperatures or porous substrates.

| Bauantrag | HPMC-Dosierung | Hauptvorteile |

|---|---|---|

| Cement renders | 0.2-0.3% | Extended workability, reduced sagging |

| Fliesenkleber | 0.3-0.5% | Improved open time, enhanced slip resistance |

| Selbstverlaufsmassen | 0.1-0.2% | Better flow, reduced bleeding |

| Gypsum-based products | 0.1-0.3% | Improved water retention, enhanced strength |

Pharmaceutical manufacturers rely on HPMC for both immediate and controlled-release drug delivery systems. In tablet formulations, HPMC functions as a binding agent at concentrations of 2-5%, providing ideal hardness without compromising disintegration. For controlled-release applications, higher concentrations (20-35%) create hydrophilic matrix systems that regulate drug release over extended periods.

The food industry utilizes HPMC as a multifunctional ingredient that improves texture, stability, and shelf life. In gluten-free baked goods, HPMC at 1-2% mimics gluten functionality, providing structure and gas retention during baking. Plant-based meat alternatives benefit from HPMC’s gelling properties, which create fibrous textures similar to animal proteins.

Personal care products leverage HPMC’s film-forming and stabilizing properties to enhance consumer experience. In shampoos and body washes, low concentrations (0.5-1.0%) provide ideal viscosity without tackiness. Skin care formulations benefit from HPMC’s ability to form breathable films that deliver active ingredients while protecting the skin surface.

| Industrie | Produkttyp | HPMC-Funktion | Qualitätsverbesserung |

|---|---|---|---|

| Konstruktion | Mortars and adhesives | Wasserrückhaltemittel | Extended working time, improved adhesion |

| Pharmazeutika | Tablet formulations | Matrix former | Controlled drug release, consistent dissolution |

| Essen | Baked goods | Texturmodifikator | Improved structure, extended freshness |

| Körperpflege | Skin care products | Filmbildner | Enhanced active delivery, improved feel |

| Farben | Water-based coatings | Rheologiemodifikator | Better application properties, reduced sagging |

4. What Are The Cost Benefits Of Incorporating HPMC In Your Products?

While HPMC may have a higher initial cost compared to some traditional additives, its economic advantages become apparent when considering the overall manufacturing process and product lifecycle.

Sie werden überrascht sein zu erfahren that incorporating HPMC often results in significant material savings across the production process.

One of the primary cost benefits comes from HPMC’s high efficiency, which allows for reduced material usage. In construction applications, for example, HPMC’s superior water retention capability means less cement is required to achieve target strength properties. Typically, a 0.3% addition of HPMC can reduce cement content by 5-10% while maintaining or improving performance standards.

Products formulated with HPMC typically exhibit extended shelf life due to improved stability. In food applications, HPMC prevents ingredient separation and texture degradation, reducing product returns and waste. Pharmaceutical formulations benefit from HPMC’s stability across temperature and humidity variations, minimizing product loss during storage and distribution.

| Kostenfaktor | Ohne HPMC | Mit HPMC | Potential Savings |

|---|---|---|---|

| Raw material usage | Baseline | 5-15% reduction | $10-30 per ton of product |

| Production efficiency | Baseline | 10-20% improvement | $15-40 per production hour |

| Product returns | 2-5% | 0.5-1% | $5-15 per thousand units |

| Energy consumption | Baseline | 5-10% reduction | $3-8 per production batch |

Manufacturing efficiency improves significantly with HPMC incorporation. Its predictable rheology and processing behavior reduce production variability, resulting in fewer batch rejections and rework requirements. In continuous manufacturing processes, HPMC’s consistent performance allows for higher production speeds without quality compromises.

When comparing HPMC to alternative additives, the cost-performance ratio often favors HPMC. While natural gums might have lower per-kilogram costs, they typically require higher dosages and often need complementary ingredients to achieve comparable functionality. Synthetic polymers may match some performance aspects but rarely provide HPMC’s multifunctionality in a single additive.

For B2B decision-makers, the long-term return on investment from HPMC adoption extends beyond direct material costs. Improved product performance leads to enhanced customer satisfaction and retention. Manufacturing efficiency gains translate to better capacity utilization and reduced labor costs.

5. How To Select The Right HPMC Grade For Your Specific Application?

Selecting the optimal HPMC grade for your application requires understanding the relationship between HPMC’s structural characteristics and functional properties. With numerous grades available in the market, a systematic approach to selection ensures the best performance outcomes.

Here’s the bottom line: Matching the right HPMC grade to your application requirements can make the difference between mediocre and exceptional product performance.

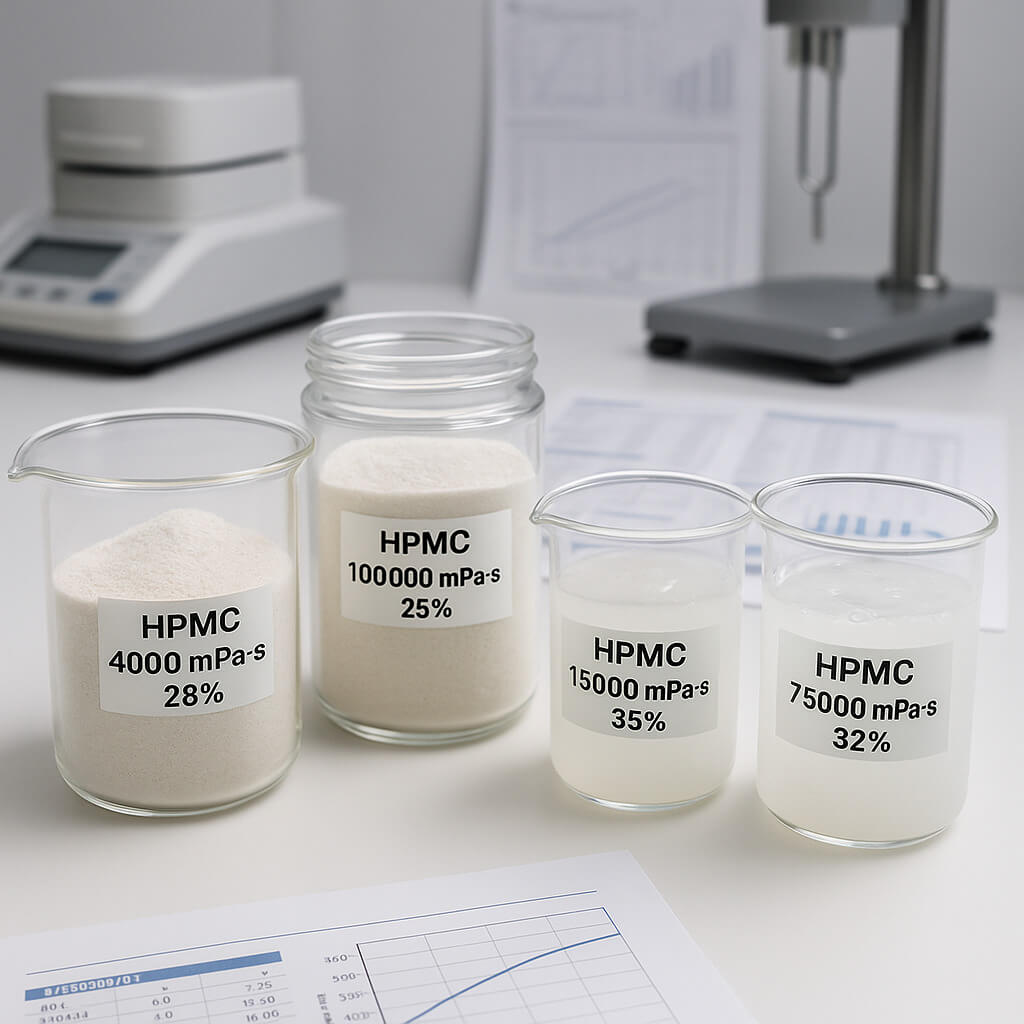

The viscosity grade of HPMC, typically expressed in millipascal-seconds (mPa·s), is perhaps the most critical selection parameter. This value, measured in a 2% aqueous solution at 20°C, ranges from very low (3-15 mPa·s) to extremely high (100,000+ mPa·s). Low-viscosity grades provide minimal thickening but excellent film-forming properties, making them ideal for coating applications. Medium-viscosity grades (4,000-15,000 mPa·s) offer balanced thickening and binding capabilities suitable for most construction and pharmaceutical applications.

Substitution type, indicated by the ratio of methoxyl to hydroxypropyl groups, significantly influences HPMC’s performance characteristics. Higher methoxyl content increases organic solubility and thermal gelation temperature, while higher hydroxypropyl content enhances water solubility and surface activity.

| Substitutionstyp | Methoxylgehalt (%) | Hydroxypropyl-Gehalt (%) | Primäre Anwendungen |

|---|---|---|---|

| E-type | 28-30 | 7-12 | Construction, general industrial |

| F-type | 27-30 | 4-7.5 | Lebensmittel, Pharmazeutika |

| K-type | 19-24 | 7-12 | Pharmaceuticals, personal care |

| J-type | 16-20 | 13-19 | Specialized applications |

Matching HPMC properties to application requirements involves considering multiple performance factors simultaneously. For construction applications, water retention capacity and workability extension are typically prioritized. Pharmaceutical applications focus on dissolution profile and matrix integrity. Food applications emphasize texture, stability, and sensory characteristics.

Testing protocols for evaluating HPMC performance should simulate actual application conditions. For construction products, open time and sag resistance tests under various temperature and humidity conditions provide valuable insights. Pharmaceutical applications require dissolution testing under physiologically relevant conditions.

Many suppliers offer customized HPMC formulations tailored to specific application requirements. These specialized products may include modified particle size distributions for improved dispersibility, surface treatments for enhanced compatibility with hydrophobic ingredients, or blends with complementary additives for synergistic effects.

6. What Are The Best Practices For Handling And Incorporating HPMC?

Proper handling and incorporation techniques are essential for maximizing HPMC’s performance benefits in your products. Following industry best practices ensures consistent results and avoids common processing issues.

You need to understand that HPMC’s unique dissolution behavior requires specific handling procedures that differ from many other additives.

Proper storage begins with maintaining appropriate warehouse conditions. HPMC should be stored in cool, dry areas with relative humidity below 65% and temperatures between 10-30°C. Original packaging should remain sealed until use to prevent moisture absorption, which can cause particle agglomeration and reduced dispersibility.

| Storage Parameter | Recommended Condition | Impact of Non-Compliance |

|---|---|---|

| Temperatur | 10-30°C | Potential caking at high temperatures |

| Relative humidity | Below 65% | Moisture absorption, reduced dispersibility |

| Packaging integrity | Sealed until use | Contamination, moisture absorption |

| Inventory rotation | FIFO system | Gradual property changes over time |

The dispersion and hydration process is critical for achieving HPMC’s full functionality. Unlike many water-soluble polymers, HPMC requires a specific incorporation technique to prevent lumping and ensure complete hydration. The most effective method follows these steps:

- Create a vortex in the water phase using appropriate agitation

- Gradually add HPMC powder to the vortex periphery

- Maintain agitation until particles are fully wetted and dispersed

- Allow sufficient hydration time (typically 30-60 minutes) for complete dissolution

Temperature control during HPMC incorporation significantly impacts dissolution efficiency. The “hot/cold” technique leverages HPMC’s thermal gelation property for efficient incorporation: HPMC is first dispersed in hot water (above 80°C) where it remains insoluble but wets thoroughly, then the mixture is cooled to allow complete dissolution.

Quality control measures should include regular testing of both incoming HPMC materials and the final product. For incoming materials, verification of moisture content, particle size distribution, and viscosity ensures consistency across batches. During production, monitoring dispersion completeness and solution viscosity provides early detection of potential issues.

| Common Issue | Potential Cause | Recommended Solution |

|---|---|---|

| Lumping during incorporation | Too rapid addition, insufficient agitation | Use powder induction system, increase agitation |

| Incomplete hydration | Insufficient time, improper temperature | Extend hydration time, optimize temperature |

| Viscosity variation | Inconsistent dispersion, temperature fluctuations | Standardize dispersion procedure, control temperature |

| Surface defects in final product | Air entrainment during mixing | Adjust mixing speed, consider defoaming agents |

| Reduced effectiveness | Incompatibility with other ingredients | Review formulation, adjust addition sequence |

Abschluss

HPMC stands as a transformative additive that can significantly improve your product performance across multiple dimensions. From its versatile technical properties to its specific benefits in various industries, HPMC offers manufacturers a powerful tool for enhancing product quality while potentially reducing overall costs. By understanding the unique characteristics of different HPMC grades and implementing proper handling techniques, your business can fully leverage this versatile polymer to gain a competitive advantage.

The evidence presented throughout this article demonstrates that HPMC incorporation typically results in a 15-30% improvement in key performance parameters while potentially reducing manufacturing costs by 5-15% through increased efficiency and reduced material usage. These tangible benefits make HPMC an invaluable component in modern manufacturing processes across construction, pharmaceutical, food, and personal care industries.

For expert guidance on selecting and implementing the optimal HPMC solution for your specific application, contact Morton’s technical team today. Our specialists can provide customized recommendations based on your unique manufacturing requirements and help you achieve superior product performance through proper HPMC utilization.

Take the next step toward enhanced product quality by partnering with Morton for comprehensive HPMC solutions that deliver measurable improvements to your manufacturing processes and final products.

FAQ-Bereich

F1: Was ist der Unterschied zwischen HPMC und anderen Zellulosederivaten?

HPMC (Hydroxypropyl Methylcellulose) differs from other cellulose derivatives primarily in its balance of hydrophilic and hydrophobic properties. Unlike MC (Methylcellulose), CMC (Carboxymethyl Cellulose), or HEC (Hydroxyethyl Cellulose), HPMC offers unique thermal gelation properties, superior film-forming capabilities, and better stability across varying pH conditions. These distinctions make HPMC particularly valuable in applications requiring controlled viscosity, excellent water retention, and stable performance across diverse manufacturing environments.

Q2: How does HPMC affect the setting time of cement-based products?

HPMC significantly extends the setting time of cement-based products by forming a protective film around cement particles, which slows water penetration and hydration reactions. This delayed setting provides longer workability time, allowing for proper application and finishing. Typically, adding 0.2-0.5% HPMC can extend workability by 30-60 minutes depending on the specific grade used. This property is particularly valuable in hot weather conditions or when working with large surface areas that require extended finishing time.

Q3: Can HPMC be used in food products, and is it safe for consumption?

Yes, specific grades of HPMC are approved for food use and are considered safe for consumption. Food-grade HPMC (E464) has undergone extensive safety evaluations by regulatory bodies including FDA and EFSA. It functions as a thickener, stabilizer, and emulsifier in various food applications including baked goods, sauces, and plant-based alternatives. Food manufacturers must ensure they source pharmaceutical or food-grade HPMC that meets appropriate regulatory standards and certification requirements for their specific market.

Q4: What concentration of HPMC is typically used in pharmaceutical tablet formulations?

In pharmaceutical tablet formulations, HPMC is typically used at concentrations ranging from 2% to 5% for standard binding applications, and 20% to 35% for controlled-release matrix systems. The exact concentration depends on the desired release profile, tablet size, and other formulation components. Lower viscosity grades (3-15 mPa·s) are preferred for immediate-release tablets, while higher viscosity grades (100,000+ mPa·s) are selected for extended-release applications where slower dissolution is required.

Q5: How does temperature affect the performance of HPMC in solutions?

Temperature significantly impacts HPMC performance in solutions through its unique inverse solubility property. At lower temperatures (below 20°C), HPMC readily dissolves and forms clear solutions with predictable viscosity. As temperature increases (typically above 60-80°C depending on the grade), HPMC undergoes thermal gelation, forming a reversible gel structure as hydrophobic interactions between molecules strengthen. This property enables applications like hot-process stability in foods and temperature-responsive drug delivery systems. For optimal processing, manufacturers should disperse HPMC in cold water before heating or in hot water after cooling to avoid lumping.