Hypromellose, also known as hydroxypropyl methylcellulose (HPMC), is a versatile polymer widely used across pharmaceutical, food, and construction industries. Understanding its viscosity grades is crucial for achieving optimal product performance and functionality. This article explores the various viscosity grades of hypromellose, their measurement methods, market availability, and application-specific considerations. Whether you’re formulating controlled-release medications, developing food products, or working with construction materials, selecting the right viscosity grade can significantly impact your product’s quality, stability, and effectiveness. Our comprehensive guide will help you navigate the complex world of hypromellose viscosity grades to make informed decisions for your specific applications.

1. What Is Hypromellose and Why Are Viscosity Grades Important?

Hypromellose, or hydroxypropyl methylcellulose (HPMC), is a semi-synthetic, inert polymer derived from cellulose. Its molecular structure consists of a cellulose backbone with methoxyl and hydroxypropyl substituent groups, which determine many of its physical properties. This white to off-white powder is odorless, tasteless, and dissolves in water to form clear solutions of varying viscosities.

Aber hier ist die Sache: viscosity is perhaps the most critical parameter when selecting hypromellose for specific applications. Viscosity refers to a fluid’s resistance to flow, and in the case of hypromellose, it directly influences how the material will perform in various formulations.

The importance of viscosity grades cannot be overstated. They determine:

| Eigentum | Impact of Viscosity Grade |

|---|---|

| Release rate | Higher viscosity grades provide slower release in controlled-release formulations |

| Filmbildung | Medium viscosity grades typically form stronger, more uniform films |

| Binding strength | Higher viscosity grades generally provide stronger binding in tablets |

| Processing ease | Lower viscosity grades are easier to pump and process |

Hypromellose finds applications across multiple industries due to its versatile properties. In pharmaceuticals, it serves as a controlled-release agent, tablet binder, and film-coating material. The food industry uses it as a thickener, stabilizer, and emulsifier. In construction, it functions as a cement modifier and water-retention agent.

Consider this carefully: selecting the wrong viscosity grade can lead to product failure, inconsistent performance, or manufacturing difficulties. Understanding the relationship between viscosity grades and performance is essential for product development and quality control.

2. How Are Viscosity Grades of Hypromellose Measured and Classified?

Measuring and classifying the viscosity of hypromellose follows standardized methods to ensure consistency across the industry. These measurements provide critical data for manufacturers and formulators who rely on precise viscosity specifications.

Sie fragen sich vielleicht: how exactly is viscosity measured for such a versatile polymer? The most common method uses rotational viscometers, particularly the Brookfield viscometer. This instrument measures the torque required to rotate a spindle in a solution of hypromellose at a specified concentration (typically 2% w/w) and temperature (usually 20°C).

The United States Pharmacopeia (USP) and European Pharmacopoeia (EP) have established standard methods for determining hypromellose viscosity:

| Parameter | USP Method | EP Method |

|---|---|---|

| Konzentration | 2% w/w | 2% w/w |

| Temperatur | 20°C ± 0.1°C | 20°C ± 0.1°C |

| Equipment | Capillary or rotational viscometer | Capillary or rotational viscometer |

| Units | mPa·s (millipascal-seconds) | mPa·s (millipascal-seconds) |

Classification systems for hypromellose viscosity grades typically follow a numerical designation that indicates the approximate viscosity in millipascal-seconds (mPa·s). For example:

| Grade Designation | Nominal Viscosity (mPa·s, 2% solution at 20°C) |

|---|---|

| E3 | 3 |

| E5 | 5 |

| E15 | 15 |

| E50 | 50 |

| E4M | 4,000 |

| E10M | 10,000 |

| E15M | 15,000 |

In this nomenclature, “E” refers to the HPMC type, the number indicates the approximate viscosity, and “M” denotes thousands. So E4M represents a grade with approximately 4,000 mPa·s viscosity.

Here’s the critical part: testing procedures must be meticulously followed to obtain accurate and reproducible results. The sample preparation involves careful dispersion of the powder in heated water, followed by cooling and addition of the remaining water. The solution must then equilibrate for 24 hours before measurement.

3. What Are the Main Viscosity Grades Available in the Market?

The market offers a wide spectrum of hypromellose viscosity grades to meet diverse application requirements. These grades range from very low to extremely high viscosities, each serving specific functions across industries.

Lassen Sie mich das klarstellen: selecting the appropriate viscosity grade is crucial for achieving desired product performance. Let’s explore the main categories available:

Low viscosity grades (E3, E5, E6, E15) are characterized by their relatively fluid nature when dissolved in water. These grades typically produce solutions with viscosities between 3-15 mPa·s (at 2% concentration and 20°C).

| Low Viscosity Grade | Typical Viscosity (mPa·s) | Primäre Anwendungen |

|---|---|---|

| E3 | 2.4-3.6 | Fast-dissolving films, eye drops |

| E5 | 4.0-6.0 | Tablet coating, ophthalmic solutions |

| E6 | 5.0-7.0 | Modified coating applications |

| E15 | 12.0-18.0 | Tablet binding, thickening |

Low viscosity grades offer excellent film-forming properties and are easier to pump and spray. They’re particularly valuable in coating applications where thin, uniform films are required.

Medium viscosity grades (E50, E4M) bridge the gap between low and high viscosities, offering balanced properties:

| Medium Viscosity Grade | Typical Viscosity (mPa·s) | Primäre Anwendungen |

|---|---|---|

| E50 | 40-60 | Sustained-release matrices, binders |

| E4M | 3,000-5,600 | Controlled-release tablets, gel formation |

Denken Sie darüber nach: medium viscosity grades provide the versatility needed for many pharmaceutical applications, particularly in controlled-release formulations where drug release needs to be modulated over several hours.

High viscosity grades (E10M, E15M) create much thicker solutions and gels:

| High Viscosity Grade | Typical Viscosity (mPa·s) | Primäre Anwendungen |

|---|---|---|

| E10M | 7,500-14,000 | Extended-release matrices, strong binding |

| E15M | 13,000-20,000 | Very slow-release formulations |

These high-viscosity grades excel in applications requiring prolonged release profiles, strong binding capabilities, or high gel strength. They form robust matrices that can control drug release over 12-24 hours or longer.

4. How Do Different Viscosity Grades Affect Pharmaceutical Applications?

In pharmaceutical applications, the viscosity grade of hypromellose plays a decisive role in determining drug release profiles, tablet integrity, and overall product performance. The selection of an appropriate grade can make the difference between a successful formulation and one that fails to meet therapeutic objectives.

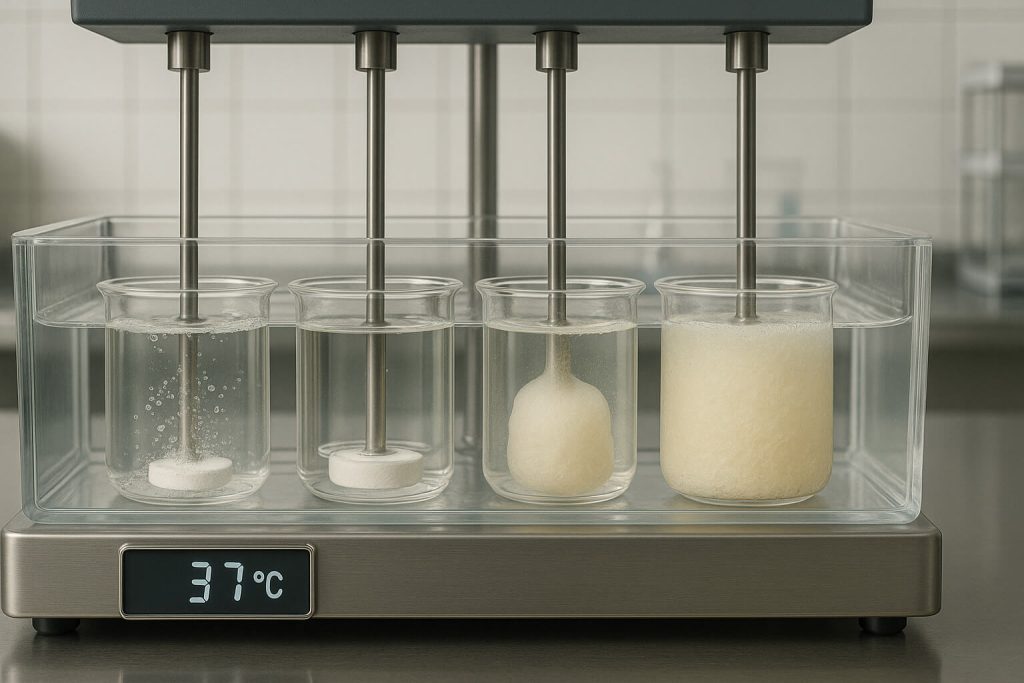

Hier ist die Realität: controlled-release formulations rely heavily on the viscosity properties of hypromellose. When a tablet containing hypromellose comes into contact with gastrointestinal fluids, the polymer hydrates and forms a gel layer around the tablet. This gel layer acts as a diffusion barrier that controls drug release.

| Viskositätsklasse | Gel Layer Formation | Drug Release Profile | Typische Dauer |

|---|---|---|---|

| Low (E3-E15) | Thin, less robust gel | Faster, less controlled | 4-8 hours |

| Medium (E50-E4M) | Moderate gel thickness | Balanced release profile | 8-16 hours |

| High (E10M-E15M) | Thick, robust gel | Slow, highly controlled | 12-24+ hours |

The impact on tablet coating performance is equally significant. Hypromellose is widely used as a film-forming agent in tablet coatings, where different viscosity grades offer varying advantages:

- Low viscosity grades (E3, E5, E6) produce thinner, more uniform coatings and are easier to spray

- Medium viscosity grades provide better adhesion and mechanical strength

- Higher viscosity grades may require more dilution but can offer enhanced barrier properties

Das sollten Sie wissen viscosity grade selection also influences drug stability and bioavailability. Higher viscosity grades generally provide better protection against environmental factors but may slow drug release and potentially impact bioavailability if not properly formulated.

A case study from a major pharmaceutical manufacturer illustrates this point: When reformulating an extended-release cardiovascular medication, changing from an E4M to an E10M grade increased the release duration from 12 to 18 hours, providing better overnight coverage for patients. However, this required adjustments to excipient levels to maintain bioequivalence.

| Case Study | Original Formulation | Reformulation | Ergebnis |

|---|---|---|---|

| Cardiovascular drug | E4M grade, 12-hour release | E10M grade, 18-hour release | Improved patient convenience |

| Pain medication | E15 grade, rapid release | E50 grade, moderate release | Better pain control |

5. What Factors Should Be Considered When Selecting Hypromellose Viscosity Grades?

Selecting the appropriate hypromellose viscosity grade requires careful consideration of multiple factors to ensure optimal performance in the final application. This decision-making process involves balancing technical requirements, processing constraints, and economic considerations.

Die Wahrheit ist, application-specific requirements should drive your initial selection. Different applications demand different viscosity profiles:

| Anwendung | Recommended Viscosity Range | Wichtige Überlegungen |

|---|---|---|

| Tabletten mit sofortiger Wirkstofffreisetzung | Low (E3-E15) | Disintegration time, binding strength |

| Extended-release matrices | Medium to High (E4M-E15M) | Release duration, drug solubility |

| Tablet coating | Low to Medium (E3-E50) | Film uniformity, barrier properties |

| Ophthalmische Lösungen | Very Low (E3-E5) | Comfort, clarity, biocompatibility |

Processing conditions and equipment compatibility represent another crucial consideration. Higher viscosity grades can present challenges during manufacturing:

- Mixing and pumping difficulties with high-viscosity grades

- Longer hydration times for higher molecular weight grades

- Potential for nozzle clogging during spray applications

- Higher energy requirements for processing

Think about this carefully: your existing equipment capabilities may limit your options. For instance, if your liquid filling line cannot handle solutions above a certain viscosity, you’ll need to select grades that work within those constraints or invest in equipment upgrades.

Cost-effectiveness and supply chain factors cannot be overlooked. While higher viscosity grades generally command premium prices, they’re often used at lower concentrations, potentially offsetting the cost difference. Additionally, consider:

- Availability from multiple suppliers to mitigate supply risks

- Regulatory status and documentation requirements

- Batch-to-batch consistency and supplier quality systems

- Lead times and minimum order quantities

6. How Do Environmental Conditions Affect Hypromellose Viscosity Performance?

Environmental conditions significantly influence how hypromellose viscosity grades perform in various applications. Understanding these effects is crucial for predicting product behavior across different usage scenarios and storage conditions.

You need to understand that temperature has perhaps the most dramatic effect on hypromellose solutions. As temperature increases, the viscosity of hypromellose solutions decreases—a property known as negative temperature coefficient. This effect varies across different viscosity grades:

| Viskositätsklasse | Viscosity Reduction (20°C to 40°C) | Recovery After Cooling |

|---|---|---|

| Low (E3-E15) | 30-40% reduction | Nearly complete |

| Medium (E50-E4M) | 40-50% reduction | Complete with slight hysteresis |

| High (E10M-E15M) | 50-60% reduction | Complete with moderate hysteresis |

This temperature sensitivity has practical implications. For instance, pharmaceutical products containing hypromellose may release drugs faster at body temperature than predicted by room-temperature dissolution testing. Similarly, food products may change consistency when heated or cooled.

pH sensitivity and stability range also affect performance. Hypromellose maintains relatively stable viscosity across a broad pH range (3-11), which is one of its advantages over some other polymers. However, extreme pH conditions can impact its behavior:

| pH-Bereich | Effect on Hypromellose | Applications Impact |

|---|---|---|

| <3 (highly acidic) | Potential acid hydrolysis over time | May reduce viscosity in storage |

| 3-11 (moderate) | Stable performance | Ideal working range for most applications |

| >11 (highly alkaline) | Accelerated degradation possible | May affect stability in certain formulations |

The fact is, humidity and storage conditions play crucial roles in maintaining the performance of hypromellose-containing products. As a hygroscopic material, hypromellose can absorb moisture from the environment, potentially affecting powder flow properties, hydration rate, and stability of finished products.

Abschluss

Understanding the various viscosity grades of hypromellose is essential for optimizing product performance across pharmaceutical, food, and construction applications. As we’ve explored, viscosity grades directly impact critical properties like release profiles, film formation, binding strength, and processing characteristics. The wide range of available grades—from low viscosity E3 to high viscosity E15M—provides formulators with precise control over product behavior.

When selecting a hypromellose grade, consider application requirements, processing conditions, environmental factors, and cost-effectiveness. Remember that environmental conditions, particularly temperature and pH, significantly influence performance. Conducting thorough testing across expected usage conditions will help ensure consistent product quality and functionality.

By applying the knowledge shared in this article, you can make informed decisions about hypromellose viscosity grades that will enhance your product development process and lead to superior end products.

FAQ-Bereich

Q1: Can different viscosity grades of hypromellose be mixed to achieve specific properties?

Yes, different viscosity grades can be blended to achieve intermediate viscosities or customize performance characteristics. This approach is commonly used in pharmaceutical formulations to fine-tune drug release profiles or in coating applications to balance spray properties and film strength. However, thorough testing is essential as blends may not behave as simple averages of their components.

Q2: How does particle size distribution relate to viscosity grades of hypromellose?

Particle size distribution affects the hydration rate but not the final solution viscosity of properly dissolved hypromellose. Finer particles hydrate more quickly, which can be advantageous in manufacturing processes where rapid gel formation is desired. Some suppliers offer specific particle size distributions within the same viscosity grade to address different processing needs.

Q3: What are the regulatory considerations for different hypromellose viscosity grades?

All hypromellose grades must comply with pharmacopeia standards (USP, EP, JP) for pharmaceutical applications or appropriate food regulations for food uses. Different viscosity grades have the same chemical structure and generally the same regulatory status, though specific grades may have more extensive documentation or usage history.

Q4: How do substitution types affect the viscosity behavior of hypromellose?

Substitution types (the ratio of methoxyl to hydroxypropyl groups) significantly influence hypromellose properties beyond viscosity, including gelation temperature, surface activity, and organic solvent solubility. For example, higher methoxyl content typically results in lower gelation temperatures. When selecting a grade, consider both the viscosity and the substitution type.

Q5: What are the latest innovations in hypromellose viscosity grade development?

Recent innovations include grades with enhanced dissolution profiles, improved thermal gelation properties, and specialized particle engineering for better dispersion. Some manufacturers have developed grades with more precise viscosity control and narrower specification ranges. Additionally, there’s growing interest in sustainable sourcing and manufacturing processes for hypromellose.