Hydroxypropyl Methylcellulose (HPMC) is a versatile material used in many industries, from construction to pharmaceuticals and food production. Its viscosity, a measure of the material’s resistance to flow, plays a critical role in determining its functionality. But here’s the kicker – the viscosity of HPMC is inversely proportional to temperature. As the temperature increases, the viscosity decreases, which can have significant implications for its applications. This article delves into how temperature affects the viscosity of HPMC, why this happens, and how industries can manage this relationship for optimal results.

1. What is HPMC and Why is Its Viscosity Important?

HPMC, or Hydroxypropyl Methylcellulose, is a non-ionic cellulose ether that is soluble in water and is widely used as a thickening agent, stabilizer, and binder. It is used in a variety of products, including adhesives, coatings, cosmetics, and pharmaceuticals. Ready for the good part? HPMC’s viscosity is crucial because it determines how well it performs in different formulations.

In construction, the viscosity of HPMC impacts how well mortars, plasters, and tile adhesives flow during application. A higher viscosity makes the material thicker and more stable, preventing it from running or dripping when applied. In the pharmaceutical industry, HPMC is used in tablet formulations and controlled-release medicines, where viscosity helps regulate the release of active ingredients. In food products, HPMC contributes to the texture and mouthfeel, providing the desired consistency in sauces and dressings.

Thus, viscosity isn’t just a technical property—it plays a fundamental role in determining the effectiveness and quality of the final product.

| Anwendung | Rolle von HPMC | Importance of Viscosity |

|---|---|---|

| Konstruktion | Mortars, adhesives, plasters | Ensures smooth application and prevents uneven spreading |

| Pharmazeutika | Tabletten mit kontrollierter Wirkstofffreisetzung | Regulates drug release rate for controlled absorption |

| Lebensmittelproduktion | Sauces, dressings, emulsions | Provides desired consistency and texture for better mouthfeel |

2. How Does Temperature Influence the Viscosity of HPMC?

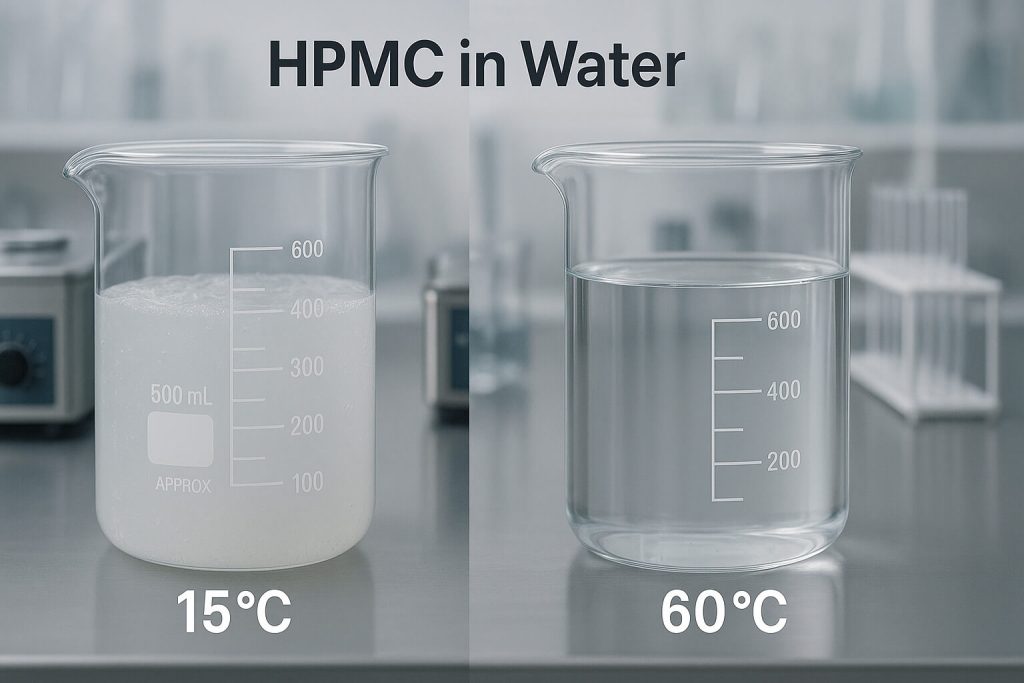

Temperature has a significant impact on the viscosity of HPMC solutions. As the temperature increases, the viscosity of HPMC decreases, meaning the material becomes more fluid and easier to spread. But what’s the real story? The reason this happens lies in the molecular structure of HPMC.

At higher temperatures, the increased molecular motion allows the polymer chains to move more freely. This reduces the intermolecular interactions, making it easier for the solution to flow. On the other hand, when the temperature drops, the polymer chains become more tightly packed, leading to higher viscosity. This inverse relationship is particularly important when considering the behavior of HPMC in different environments and applications.

In practical terms, temperature fluctuations can significantly impact the application of HPMC-based products. For instance, in construction, high temperatures during the application of mortars or adhesives could lead to a thinner, runnier consistency, making the product difficult to control. In pharmaceuticals, variations in temperature could alter the release rate of controlled-release medications, potentially affecting their efficacy.

| Temperatur | Viskositätseffekt | Auswirkungen auf die Anwendung |

|---|---|---|

| Hoch | Decreased viscosity | Easier application, less control |

| Niedrig | Increased viscosity | Thicker consistency, harder to spread |

3. Why Does Viscosity Decrease as Temperature Increases?

So, why does viscosity decrease as temperature increases? Ready for the good part? The explanation lies in the fundamental properties of polymer solutions like HPMC. HPMC molecules consist of long chains of cellulose that interact with each other through hydrogen bonds and Van der Waals forces. These interactions create resistance to flow, which is measured as viscosity.

When the temperature increases, the kinetic energy of the molecules also increases. This increased energy breaks the hydrogen bonds and weakens the intermolecular forces between polymer chains. As a result, the polymer chains can move more freely, allowing the solution to flow more easily and reducing viscosity.

This phenomenon is similar to how liquids in general behave—think of how water becomes less viscous when heated. In industrial applications, this decrease in viscosity can either be a benefit or a challenge, depending on the desired outcome. In construction, for example, lower viscosity at high temperatures may make mortars easier to apply but harder to control. In pharmaceuticals, lower viscosity can improve the dissolution of active ingredients, but it could also affect the controlled release of medication.

| Temperatur | Effect on Molecular Motion | Einfluss der Viskosität |

|---|---|---|

| Hoch | Increased kinetic energy | Decreased viscosity |

| Niedrig | Decreased kinetic energy | Increased viscosity |

4. How Can Temperature Variations Be Controlled in Industrial Applications?

Temperature fluctuations can dramatically affect HPMC performance, but here’s the kicker – manufacturers can control these variations through several strategies. In the pharmaceutical industry, temperature-controlled environments are often used during the mixing and storage of HPMC-based products. This ensures that the viscosity remains consistent and that the drug release properties are not compromised.

In construction, temperature control during the mixing of mortars and adhesives can prevent issues with viscosity. For example, in hot weather, using cool water during the mixing process can help maintain the desired consistency of the mortar. Conversely, in cold climates, additives or chemical accelerators may be used to increase the flowability and reduce the thickening of the mixture.

By using temperature-regulated systems and carefully monitoring environmental conditions, manufacturers can ensure that HPMC behaves as expected, providing consistent results across different applications.

| Temperature Control Method | Einfluss auf die Viskosität | Anwendung |

|---|---|---|

| Cool water for mixing | Maintains viscosity | Bau, Klebstoffe |

| Heating systems in production | Reduces viscosity | Pharmaceuticals, controlled release |

5. How Does the Inverse Relationship Between Viscosity and Temperature Affect HPMC in Pharmaceuticals?

In the pharmaceutical industry, the relationship between temperature and viscosity plays a pivotal role in the formulation of controlled-release tablets. What’s the real story here? When HPMC is used in tablet formulations, its viscosity influences the rate at which the active ingredient is released into the body.

As the temperature increases, HPMC’s viscosity decreases, which can alter the rate of drug release. This is particularly important during the manufacturing process, where temperature must be carefully controlled to ensure that the tablets dissolve at the correct rate. In storage, changes in environmental temperature can also affect the consistency of HPMC, potentially causing variations in the drug release profile.

Temperature-induced viscosity changes are not just theoretical; they are practically important in the development of medications that must maintain a specific release time for therapeutic efficacy. By managing temperature during both production and storage, pharmaceutical companies can ensure that their products remain consistent and reliable.

| Temperature Change | Viscosity Change | Effect on Drug Release |

|---|---|---|

| Hoch | Decreased viscosity | Faster release of ingredients |

| Niedrig | Increased viscosity | Slower, controlled release |

6. How Does Temperature Impact the Use of HPMC in Construction Materials?

In construction, the viscosity of HPMC is directly tied to the workability of materials like mortars, plasters, and adhesives. But here’s the kicker – temperature fluctuations during application can cause significant changes in viscosity, which affects how these materials perform on the job site.

In hot conditions, the viscosity of HPMC-based products may decrease, making the mixture too thin and difficult to control. This could lead to a less uniform finish and even cause the material to run or drip. In colder environments, the opposite occurs—the viscosity increases, leading to a thicker, more difficult-to-apply mixture. In both cases, adjustments need to be made to ensure that the product remains easy to use and performs as expected.

For example, in extreme heat, manufacturers may use cool water or chemical additives to maintain the ideal viscosity for mortars and adhesives. Similarly, in colder climates, accelerators or additives can be used to improve the flow and workability of the material.

| Temperatur | Einfluss der Viskosität | Workability Effect |

|---|---|---|

| Hoch | Decreased viscosity | Harder to control, less stable |

| Niedrig | Increased viscosity | Thicker, harder to spread |

7. How Can Manufacturers Adjust for Temperature-Induced Changes in Viscosity?

Manufacturers can adapt to temperature-induced viscosity changes by adjusting their formulations and processes. Ready for the good part? By using a combination of additives and temperature-regulated environments, manufacturers can ensure that HPMC behaves as expected despite temperature fluctuations.

In construction, the viscosity of HPMC-based mortars can be adjusted by adding plasticizers or thickeners to maintain the desired flow properties in hot or cold conditions. In pharmaceuticals, HPMC concentrations can be altered to compensate for changes in viscosity, ensuring that the controlled-release characteristics are not affected by temperature.

In both industries, temperature control is key. Using temperature-controlled mixing environments and carefully monitoring the curing or setting process can mitigate the effects of temperature changes and maintain consistency.

| Adjustment Method | Einfluss auf die Viskosität | Anwendung |

|---|---|---|

| Additives (plasticizers, thickeners) | Alters viscosity for better flow | Bau, Pharma |

| Temperature-controlled mixing | Stabilisiert die Viskosität | Mortars, controlled-release tablets |

8. How Does Temperature Affect the Solubility of HPMC in Various Solutions?

Temperature plays a significant role in the solubility of HPMC. As temperature increases, HPMC dissolves more easily in water, which can impact its viscosity and performance. In industrial applications, controlling solubility is essential for ensuring that HPMC behaves predictably during formulation and processing.

For example, in pharmaceuticals, high temperatures may improve the dissolution rate of HPMC, but too high a temperature could cause the polymer to degrade or lose its functionality. Similarly, in food products, changes in temperature can affect

the texture and consistency of HPMC-based emulsions and gels.

Controlling temperature during the mixing process ensures that HPMC remains stable and functions as intended in various solutions.

| Temperatur | Einfluss auf die Löslichkeit | Einfluss auf die Viskosität |

|---|---|---|

| Hoch | Erhöhte Löslichkeit | Decreased viscosity |

| Niedrig | Decreased solubility | Increased viscosity |

9. What Are the Key Factors to Consider When Using HPMC in Temperature-Sensitive Environments?

When using HPMC in environments with fluctuating temperatures, several factors need to be considered to ensure consistency. What’s the real story? The main factors include controlling ambient temperature, adjusting formulation parameters, and using temperature-stable additives.

In some industries, such as pharmaceuticals and food production, it is critical to maintain consistent temperatures during processing and storage to prevent viscosity changes. The use of climate-controlled warehouses and temperature-regulated mixing systems ensures that products maintain their intended viscosity, ensuring high-quality end products.

| Umweltfaktor | Effect on HPMC | Mitigation Strategy |

|---|---|---|

| Temperature fluctuations | Viscosity changes | Use of temperature-controlled environments |

| Luftfeuchtigkeit | Affects water retention | Adjusting concentration and additives |

10. How Can Temperature-Related Viscosity Changes Be Mitigated in HPMC-Based Products?

To mitigate the effects of temperature on HPMC viscosity, manufacturers can modify the formulation by adjusting concentrations, adding stabilizers, or using temperature-resistant additives. For instance, plasticizers can reduce viscosity in high temperatures, while thickeners can help maintain viscosity in cold conditions.

Testing and adjusting formulations for specific environmental conditions ensure that HPMC products remain consistent and effective.

| Mitigation Strategy | Einfluss auf die Viskosität | Anwendung |

|---|---|---|

| Adding stabilizers | Maintains viscosity | Pharmazeutika, Bau |

| Using plasticizers | Reduces viscosity | Mörtel, Klebstoffe |

Abschluss

In conclusion, the viscosity of Hydroxypropyl Methylcellulose (HPMC) is inversely related to temperature, meaning its viscosity decreases as temperature increases. This phenomenon can have significant effects on its performance in industries such as pharmaceuticals, construction, and food production. By understanding how temperature affects viscosity, manufacturers can implement strategies to control temperature and adjust formulations to ensure optimal performance in various applications.

FAQ-Bereich

Frage 1: Was ist Hydroxypropylmethylcellulose (HPMC)?

A1: HPMC is a cellulose derivative widely used as a thickener, stabilizer, and emulsifier in various industries, including pharmaceuticals, food production, and construction.

Frage 2: How does temperature affect the viscosity of HPMC?

Antwort: As temperature increases, the viscosity of HPMC decreases. This is because higher temperatures allow the polymer chains to move more freely, reducing resistance to flow.

Frage 3: Why is temperature control important when using HPMC?

Antwort Nr. 3: Temperature control is critical because fluctuations can significantly impact the viscosity of HPMC, affecting its performance in applications like drug release and mortar application.

Frage 4: How can manufacturers adjust for temperature-related viscosity changes in HPMC-based products?

Antwort Nr. 4: Manufacturers can adjust formulations by using temperature-regulated environments, adding stabilizers or plasticizers, and modifying concentrations to ensure consistent viscosity.

F5: Welchen Einfluss hat die Temperatur auf die Löslichkeit von HPMC?

Antwort Nr. 5: Higher temperatures increase the solubility of HPMC, which can lower its viscosity. This must be carefully managed to ensure the desired product consistency and performance.