Hypromellose, also known as hydroxypropyl methylcellulose (HPMC), is a versatile excipient that plays a crucial role in modern pharmaceutical formulations. If you’re involved in pharmaceutical product development or procurement, understanding how this polymer functions can help you make better decisions for your formulations. This article explores the mechanisms behind hypromellose’s effectiveness across various pharmaceutical applications, from controlled release systems to film coating. We’ll examine its chemical properties, functional characteristics, and practical applications to give you a comprehensive understanding of why this excipient has become indispensable in pharmaceutical manufacturing.

1. What is Hypromellose and How is it Classified?

Hypromellose is a semi-synthetic, inert polymer derived from cellulose. It’s created through chemical modification of cellulose pulp, where some hydroxyl groups are replaced with methoxy and hydroxypropyl substituents. But here’s what makes it special: this substitution pattern gives hypromellose its unique properties that are highly valuable in pharmaceutical applications.

The chemical structure of hypromellose consists of a cellulose backbone with methoxyl and hydroxypropyl substituents. These substituents alter the polymer’s hydrophilic-hydrophobic balance, solubility characteristics, and thermal gelation properties. The degree of substitution significantly influences its behavior in different environments and applications.

Hypromellose is classified based on several parameters, including viscosity, substitution type, and molecular weight. The United States Pharmacopeia (USP) and European Pharmacopoeia (Ph. Eur.) classify hypromellose according to the percentage of methoxyl and hydroxypropyl groups, as well as the viscosity of a 2% aqueous solution.

| Classification Parameter | Description | Examples |

|---|---|---|

| Substitution Type | Indicated by a four-digit number | HPMC 2208, HPMC 2910 |

| Viscosity | Based on viscosity of 2% solution | 4000 mPa·s, 100,000 mPa·s |

| Molecular Weight | Ranges from low to high | 10,000-1,500,000 Da |

| Application Category | Based on primary use | Controlled release, coating, binding |

Different grades of hypromellose offer varying properties suitable for specific pharmaceutical applications. Low-viscosity grades are typically used for film coating, while high-viscosity grades are preferred for controlled release matrix systems. Medium-viscosity grades often serve as binders in tablet formulations.

When compared to other cellulose derivatives like methylcellulose, ethylcellulose, or hydroxyethylcellulose, hypromellose offers distinct advantages. The key difference lies in its balance of properties: it provides excellent film-forming capabilities, controlled hydration rates, and thermal gelation characteristics that make it particularly versatile across multiple pharmaceutical applications.

2. How Does Hypromellose Function as a Controlled Release Agent?

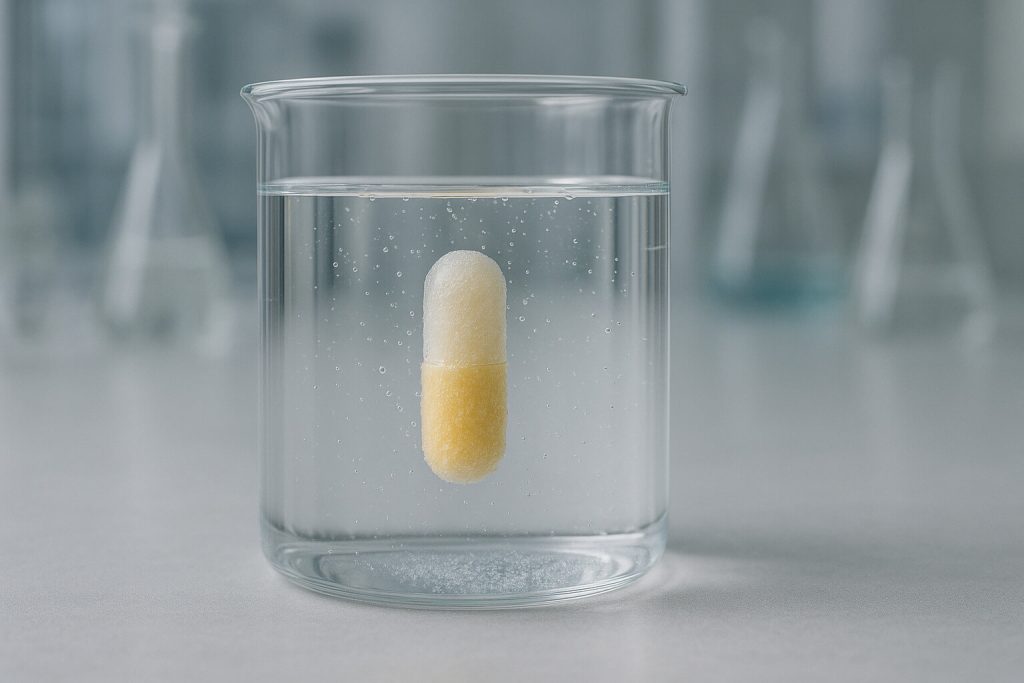

The controlled release mechanism of hypromellose is based on its ability to form a gel layer when it comes into contact with aqueous media. This is where things get interesting: when a hypromellose-based matrix tablet encounters gastrointestinal fluids, the polymer chains on the surface begin to hydrate rapidly, creating a protective gel layer around the tablet.

This gel layer formation follows a specific sequence: initial wetting of the polymer, followed by hydration, swelling, and eventually, polymer chain relaxation. As water continues to penetrate deeper into the matrix, the gel layer grows thicker. Simultaneously, the outer, fully hydrated portion of the gel begins to erode, creating a dynamic equilibrium between swelling and erosion.

The drug release from a hypromellose matrix occurs through a combination of diffusion and erosion mechanisms. For water-soluble drugs, diffusion through the gel layer is the predominant release mechanism. For poorly soluble drugs, the erosion of the gel layer plays a more significant role in controlling release.

| Factor | Effect on Drug Release | Practical Implication |

|---|---|---|

| HPMC Viscosity Grade | Higher viscosity = slower release | Select grade based on desired release profile |

| Polymer Concentration | Higher concentration = slower release | Typically 20-50% of tablet weight |

| Drug Solubility | Soluble drugs release faster | May require higher polymer concentration |

| Tablet Shape | Surface area affects release rate | Cylindrical tablets provide more uniform release |

| pH of Medium | Minimal effect on HPMC matrices | Advantage over pH-dependent polymers |

Several factors influence the drug release kinetics from hypromellose matrices. The viscosity grade of the polymer has a direct impact on release rate, with higher viscosity grades providing slower release. The polymer-to-drug ratio, particle size of both drug and polymer, and the presence of other excipients also significantly affect release patterns.

Case studies have demonstrated hypromellose’s effectiveness in controlled release formulations. For instance, once-daily formulations of highly water-soluble drugs like metformin hydrochloride have been successfully developed using high-viscosity hypromellose grades. Similarly, poorly soluble drugs like nifedipine have been formulated into extended-release tablets using optimized hypromellose matrices.

3. What Role Does Hypromellose Play in Film Coating?

Hypromellose excels as a film-forming agent due to its ability to form smooth, strong, and flexible films when applied to tablet surfaces. And here’s what you need to know: the film formation mechanism involves the deposition of polymer particles onto the tablet surface, followed by coalescence of these particles to form a continuous film as the solvent evaporates.

The film formation process begins with atomization of the coating solution, followed by droplet contact with the tablet surface, spreading, and finally coalescence and film formation. This process is influenced by the polymer’s molecular weight, concentration, and the coating conditions.

| Coating Parameter | Optimal Range | Effect on Coating Quality |

|---|---|---|

| Spray Rate | 2-10 g/min/kg | Too high: picking, twinning; Too low: inefficient process |

| Inlet Air Temperature | 40-60°C | Too high: premature drying; Too low: tacky coating |

| Tablet Bed Temperature | 35-45°C | Controls film formation and prevents defects |

| Pan Speed | 10-20 rpm | Ensures uniform coating distribution |

| Atomization Pressure | 1.0-2.5 bar | Affects droplet size and distribution |

Compared to other coating polymers like polyvinyl alcohol (PVA) or polymethacrylates, hypromellose offers several advantages. The real benefit is its versatility: it provides excellent film properties without the need for plasticizers, though they can be added to enhance flexibility. It’s also compatible with a wide range of colorants, opacifiers, and functional additives.

Common hypromellose coating formulations typically contain the polymer (5-10%), a plasticizer like polyethylene glycol (0-2%), colorants, and sometimes additional functional ingredients like talc or titanium dioxide. These formulations are usually prepared in water, ethanol, or mixtures of the two, depending on the sensitivity of the active ingredient to moisture.

The coating process parameters significantly affect the quality of hypromellose films. Spray rate, atomization pressure, pan speed, and drying conditions must be carefully controlled to achieve uniform, defect-free coatings. Modern coating equipment with precise control of these parameters has made the process more reliable and reproducible.

Hypromellose coatings find applications in immediate-release tablets (where they provide moisture protection, taste masking, and improved appearance), enteric-coated tablets (when combined with enteric polymers), and as sub-coats in multi-layered coating systems.

4. How Does Hypromellose Enhance Solubility and Bioavailability?

Hypromellose plays a crucial role in enhancing the solubility and bioavailability of poorly soluble drugs. This is particularly important because: approximately 40% of approved drugs and nearly 90% of developmental pipeline compounds have poor water solubility, presenting significant challenges for formulation scientists.

The solubilization mechanism of hypromellose involves several pathways. First, it can act as a crystallization inhibitor, maintaining the drug in an amorphous, high-energy state with enhanced solubility. Second, it can form hydrogen bonds with drug molecules, improving their wettability and dissolution rate. Third, it can create a microenvironment around drug particles that facilitates dissolution.

| Solubility Enhancement Technique | Mechanism | Example Drugs |

|---|---|---|

| Solid Dispersions | Drug molecularly dispersed in polymer matrix | Itraconazole, Nifedipine |

| Spray-Dried Dispersions | Rapid solvent evaporation traps drug in amorphous state | Tacrolimus, Fenofibrate |

| Hot-Melt Extrusion | Thermal processing creates molecular dispersion | Ritonavir, Efavirenz |

| Co-precipitation | Drug and polymer co-precipitated from solution | Celecoxib, Carbamazepine |

Solid dispersion technology using hypromellose has emerged as one of the most effective approaches for improving drug solubility. In this approach, the drug is molecularly dispersed within a hypromellose matrix, typically through spray drying, hot-melt extrusion, or co-precipitation methods. The resulting amorphous solid dispersion (ASD) exhibits significantly enhanced dissolution rates compared to crystalline drug forms.

The impact on dissolution rate and bioavailability can be substantial. Studies have shown that hypromellose-based solid dispersions can increase the dissolution rate of poorly soluble drugs by 10-100 fold, leading to significant improvements in bioavailability. For instance, the bioavailability of itraconazole from a hypromellose-based solid dispersion was found to be 2-3 times higher than from the crystalline form.

Stability considerations are critical when using hypromellose for solubility enhancement. The main challenge is this: amorphous forms of drugs are inherently unstable and tend to recrystallize over time, negating the solubility advantage. Hypromellose helps maintain stability by forming hydrogen bonds with drug molecules, increasing the glass transition temperature of the system, and creating a physical barrier to crystallization.

5. What Are the Viscosity Mechanisms of Hypromellose in Liquid Formulations?

The rheological properties of hypromellose solutions are central to their functionality in liquid formulations. What makes this particularly useful is: hypromellose exhibits pseudoplastic (shear-thinning) behavior, meaning its viscosity decreases under shear stress and recovers when the stress is removed. This property makes it ideal for ophthalmic and topical preparations, as it flows easily during application but maintains thickness once in place.

Hypromellose is available in various viscosity grades, typically ranging from 3 to 100,000 mPa·s (measured for a 2% aqueous solution at 20°C). The viscosity is primarily determined by the molecular weight of the polymer, which can be controlled during the manufacturing process.

| Viscosity Grade | Typical Applications | Concentration Range |

|---|---|---|

| Low (3-15 mPa·s) | Film coating, eye drops | 0.5-5% |

| Medium (40-400 mPa·s) | Suspensions, binding agent | 1-10% |

| High (1,500-30,000 mPa·s) | Controlled release, thickening | 0.5-5% |

| Ultra-high (>50,000 mPa·s) | Matrix tablets, sustained release | 10-40% |

One of the most distinctive features of hypromellose is its temperature-dependent gelation mechanism. Here’s what happens: unlike most polymers that decrease in viscosity as temperature increases, hypromellose solutions exhibit an increase in viscosity with rising temperature, eventually forming a gel at a specific temperature point. This thermal gelation is reversible and is attributed to the hydrophobic interaction between methoxy groups at elevated temperatures.

This thermal gelation property is particularly valuable in ophthalmic formulations, where the solution is liquid at room temperature for easy administration but forms a gel at eye temperature (35-36°C), increasing residence time and drug bioavailability. Similar benefits apply to nasal and topical formulations.

In ophthalmic preparations, hypromellose typically serves as a viscosity enhancer and artificial tear component. Concentrations of 0.3-0.5% provide lubrication without blurring vision. In topical preparations, higher concentrations (1-3%) create gels with good spreadability and skin feel.

The stability of hypromellose solutions is generally excellent across a wide pH range (3-11), making it compatible with many active ingredients. However, extreme pH conditions, high salt concentrations, or certain preservatives can affect solution viscosity and stability. Proper selection of grade and concentration is essential for maintaining stability throughout the product’s shelf life.

6. How is Hypromellose Used in Novel Drug Delivery Systems?

Hypromellose has become a cornerstone in the development of advanced drug delivery systems. The exciting part is that: its versatility allows for application in increasingly sophisticated delivery technologies that offer precise control over drug release profiles and targeting.

In matrix tablets and osmotic pump systems, hypromellose serves different but complementary roles. In matrix systems, it forms the hydrophilic matrix that controls drug release through diffusion and erosion, as discussed earlier. In osmotic pump systems, it can function as a semipermeable membrane that allows water influx but prevents drug efflux except through a laser-drilled orifice, providing near zero-order release kinetics.

| Delivery System | Role of Hypromellose | Advantage |

|---|---|---|

| Matrix Tablets | Forms hydrophilic swellable matrix | Simple manufacturing, cost-effective |

| Osmotic Pumps | Creates semipermeable membrane | Zero-order release, independent of GI conditions |

| Nanoparticles | Surface modifier, stabilizer | Enhanced permeability and targeting |

| 3D Printed Dosage Forms | Primary polymer in printable formulations | Personalized medicine, complex release profiles |

| Mucoadhesive Systems | Provides adhesion to mucosal surfaces | Prolonged residence time at absorption site |

In nanotechnology-based delivery systems, hypromellose plays multiple roles. It can serve as a stabilizer for nanoparticles, preventing aggregation and maintaining colloidal stability. It can also function as a surface modifier, altering the surface properties of nanoparticles to improve their interaction with biological membranes or to evade immune recognition. Additionally, hypromellose-based nanoparticles themselves can be used as drug carriers for targeted delivery.

The emergence of 3D printing in pharmaceutical manufacturing has created new opportunities for hypromellose. Its excellent film-forming properties and thermal stability make it an ideal polymer for various 3D printing technologies, including fused deposition modeling (FDM) and pressure-assisted microsyringe (PAM) printing. Hypromellose-based 3D printed dosage forms offer the potential for personalized medicine with complex release profiles that would be difficult to achieve with conventional manufacturing methods.

Future trends in advanced delivery systems involving hypromellose include stimuli-responsive systems that release drugs in response to specific triggers (pH, temperature, enzymes), combination products that deliver multiple drugs with different release profiles from a single dosage form, and targeted delivery systems that utilize hypromellose derivatives with specific targeting moieties.

Conclusion

Hypromellose stands as one of the most versatile excipients in modern pharmaceutical formulations, with mechanisms that enable controlled release, film coating, solubility enhancement, viscosity modification, and advanced drug delivery. Its unique chemical structure, with balanced hydrophilic and hydrophobic properties, allows it to perform multiple functions across diverse applications.

The mechanisms discussed in this article—from gel layer formation in controlled release systems to thermal gelation in ophthalmic preparations—demonstrate why hypromellose has become indispensable in pharmaceutical development. For pharmaceutical professionals, understanding these mechanisms provides valuable insights for formulation design and optimization.

As pharmaceutical technology continues to advance, hypromellose is likely to remain at the forefront, evolving with new applications and modified forms to meet emerging challenges. Whether you’re developing a simple tablet coating or a complex targeted delivery system, the fundamental mechanisms of hypromellose provide a solid foundation for innovation and problem-solving in pharmaceutical formulation.

FAQ

Q1: Is Hypromellose safe for long-term pharmaceutical use?

Yes, hypromellose has an excellent safety profile for long-term pharmaceutical use. It is generally recognized as safe (GRAS) by the FDA and has been used in pharmaceutical products for decades. It is non-toxic, non-irritating, and non-allergenic. Hypromellose is not metabolized in the body and is excreted unchanged, minimizing the risk of systemic effects. Numerous toxicological studies have confirmed its safety, even at high doses, making it suitable for chronic medication formulations.

Q2: How does the molecular weight of Hypromellose affect its performance?

The molecular weight of hypromellose directly influences its viscosity, which in turn affects its performance in various applications. Higher molecular weight grades produce more viscous solutions and form stronger, more durable gel layers in controlled release applications, resulting in slower drug release rates. Lower molecular weight grades provide less viscous solutions suitable for coating applications where rapid film formation is desired. The molecular weight also affects the polymer’s ability to inhibit crystallization in solid dispersions, with higher molecular weight grades generally providing better crystallization inhibition.

Q3: Can Hypromellose be combined with other polymers for enhanced functionality?

Yes, hypromellose is frequently combined with other polymers to achieve enhanced functionality or overcome limitations. Common combinations include hypromellose with ethylcellulose for modified release profiles, hypromellose with carbomers for improved mucoadhesion, and hypromellose with polymethacrylates for enteric coating applications. These polymer blends can provide synergistic effects, such as better control over drug release kinetics, improved mechanical properties of films, or enhanced stability of formulations. The compatibility of hypromellose with a wide range of other polymers makes it particularly valuable in complex formulation development.

Q4: What are the stability considerations when using Hypromellose in formulations?

When using hypromellose in formulations, several stability factors must be considered. While hypromellose itself is stable across a wide pH range (3-11) and temperature conditions, its functional performance can be affected by formulation components and storage conditions. In solid dosage forms, moisture uptake can alter the release profile of controlled release formulations. In liquid formulations, extreme pH, high electrolyte concentrations, or certain preservatives can affect solution viscosity. For solid dispersions, the main stability concern is preventing drug recrystallization, which requires careful selection of the appropriate hypromellose grade and drug-to-polymer ratio. Stability studies under various conditions are essential to ensure consistent performance throughout the product’s shelf life.

Q5: How does Hypromellose compare to natural gums in controlled release applications?

Compared to natural gums like xanthan gum, guar gum, or alginates, hypromellose offers several advantages in controlled release applications. Hypromellose provides more consistent and predictable release profiles due to its well-defined chemical structure and manufacturing control, whereas natural gums can show batch-to-batch variability. Hypromellose is less susceptible to enzymatic degradation in the gastrointestinal tract, ensuring more reliable performance across different patients. It also exhibits minimal pH-dependent behavior, allowing for consistent drug release throughout the GI tract. While natural gums may offer cost advantages or specific functional benefits in some applications, hypromellose generally provides superior reproducibility, stability, and versatility for controlled release formulations.