Understanding the differences between Hydroxypropyl Methylcellulose (HPMC) and Methylcellulose is crucial for professionals in various industries, from pharmaceuticals to construction. These compounds are widely used for their versatility in different applications, but choosing the right one can be tricky. This article will explore the key differences, applications, and considerations that help businesses make the right choice between these two cellulose derivatives. If you’re in the market for either of these compounds, keep reading as we break it down for you.

1. What are HPMC and Methylcellulose?

Hydroxypropyl Methylcellulose (HPMC) and Methylcellulose are both cellulose derivatives, but they serve different purposes across various industries. To understand which one fits your needs, it’s essential to know their distinct properties and applications.

HPMC is a non-ionic compound derived from natural cellulose. It is widely used as a thickening agent, binder, and film-forming agent. In the pharmaceutical industry, it plays a pivotal role in tablet coatings, controlled-release formulations, and suspensions. It is also a staple in the construction industry, where it is used to enhance the workability of mortars and adhesives.

On the other hand, Methylcellulose is a cellulose ether that, unlike HPMC, has a unique property: it is soluble in cold water and forms gels when heated. This characteristic makes it especially useful in food products and personal care formulations. Methylcellulose is commonly used in the food industry for its ability to create stable emulsions and improve texture in plant-based products.

But here’s the kicker… While both compounds come from cellulose, their applications and performance characteristics differ significantly. Understanding how each performs in specific settings is key to making an informed decision.

| Property | HPMC | Methylcellulose |

|---|---|---|

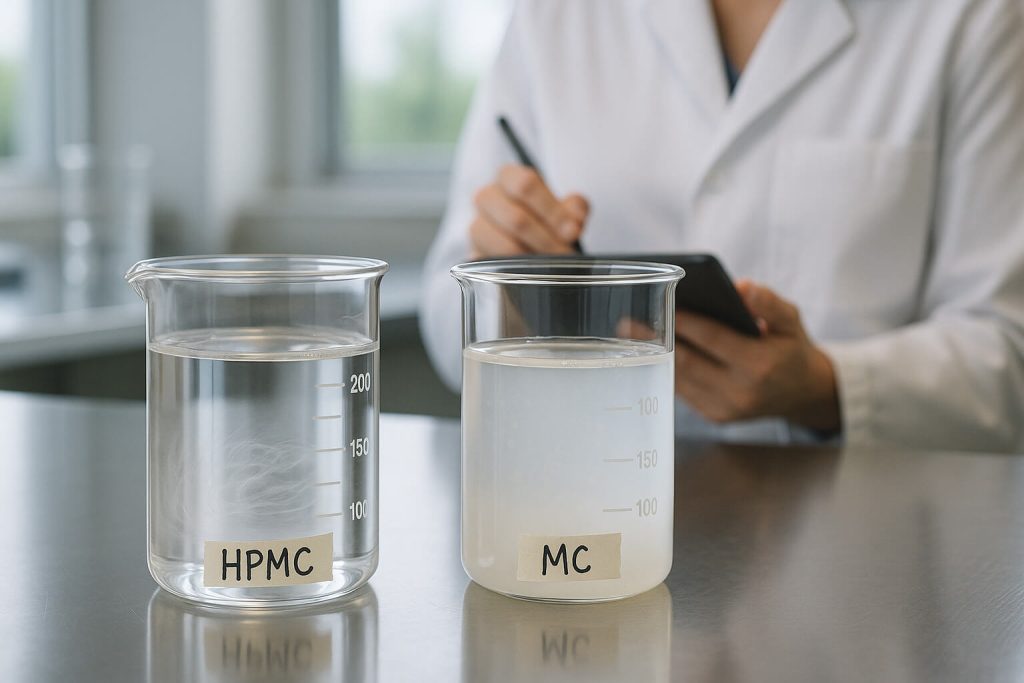

| Solubility | Soluble in hot water | Soluble in cold water, gels when heated |

| Common Uses | Pharmaceuticals, Construction | Food, Personal Care, Pharmaceuticals |

| Gel Forming Behavior | Does not form gels | Forms gels when heated |

| Viscosity Control | Excellent for thickening | Used for texture and emulsions |

2. How do HPMC and Methylcellulose Differ?

When it comes to choosing between HPMC and Methylcellulose, the key differences lie in their chemical structures and functional properties. These distinctions influence their suitability for different applications across industries.

First off, HPMC has a higher solubility in hot water compared to Methylcellulose. This property makes HPMC ideal for creating stable suspensions and pastes, particularly in pharmaceuticals. For example, it is often used in tablet coatings to control the release of active ingredients over time. It’s also utilized in construction for products like tile adhesives and joint compounds, where its thickening and water-retention properties are essential.

Methylcellulose, however, behaves differently. It is more soluble in cold water and forms gels when heated. This unique property is a game-changer in food manufacturing, where it is used to stabilize emulsions, especially in plant-based or dairy-free products. Methylcellulose also plays a role in personal care products like shampoos and lotions, where its ability to act as a thickener and stabilizer is highly valued.

So, why does this matter? When selecting between these two, understanding the solubility and gel-forming behavior is crucial. For industries needing a thickening agent that operates in high-heat environments, HPMC may be the right choice. Methylcellulose is the go-to option when cold-water solubility and gel formation are required, especially in food and cosmetic applications.

| Feature | HPMC | Methylcellulose |

|---|---|---|

| Solubility | Hot water | Cold water |

| Gel Forming Ability | Does not gel | Gels when heated |

| Industry Application | Pharmaceuticals, Construction | Food, Cosmetics, Pharmaceuticals |

3. Why Do Industries Choose HPMC or Methylcellulose?

Both HPMC and Methylcellulose are essential in their respective fields due to their specific benefits. Understanding why industries choose one over the other can help businesses make better decisions about their material needs.

For the pharmaceutical industry, HPMC is a preferred choice due to its ability to control the release of drugs. It’s used in controlled-release tablets, suspensions, and as a binder in tablet formulations. The stability and non-toxic nature of HPMC make it an ideal ingredient in drugs and health supplements.

Methylcellulose, on the other hand, is commonly used in the food and beverage industry. Its unique ability to form gels when heated makes it a key ingredient in plant-based foods, where it helps mimic the texture of traditional animal-based products. It also finds applications in the cosmetic industry, particularly in lotions and shampoos, where it enhances viscosity and stabilizes emulsions.

This is where it gets interesting… The decision to use either HPMC or Methylcellulose depends heavily on the specific needs of the product. If you’re creating a product where gel formation is crucial, Methylcellulose may be your best bet. If stability and viscosity are more important, HPMC is the superior choice.

| Industry | Preferred Compound | Reason for Choice |

|---|---|---|

| Pharmaceuticals | HPMC | Controlled release, binder, stability |

| Food & Beverage | Methylcellulose | Gel formation, texture enhancement |

| Cosmetics | Methylcellulose | Viscosity control, emulsification |

| Construction | HPMC | Thickening agent, water retention |

4. Which Factors Should You Consider When Choosing Between HPMC and Methylcellulose?

Making the right decision between HPMC and Methylcellulose involves several critical factors. Here’s what to keep in mind when deciding which compound best suits your needs.

First, consider viscosity and dissolution rates. If your product requires a thickening agent that dissolves well in hot water, HPMC is likely the better choice. For products that need a gel-like texture when exposed to heat, Methylcellulose is more appropriate.

Another consideration is cost-effectiveness and availability. In some cases, Methylcellulose may be more expensive due to its unique properties. However, depending on the application, it may offer significant benefits that justify the additional cost. Additionally, depending on your location and production capacity, sourcing these compounds might be easier in certain markets.

Don’t overlook regulatory standards. HPMC and Methylcellulose both comply with several international standards such as USP, EP, and JP. However, industries like pharmaceuticals may have more stringent requirements for quality control and testing, which may influence your choice.

What’s the real story? When selecting between HPMC and Methylcellulose, weigh all these factors carefully to ensure you select the best fit for your product.

| Factor | HPMC | Methylcellulose |

|---|---|---|

| Viscosity Control | Excellent for thickening | Used for texture and emulsions |

| Cost Effectiveness | More cost-effective | Higher cost for specialized uses |

| Regulatory Compliance | Complies with USP, EP, JP | Meets industry standards |

5. How Does HPMC Compare to Methylcellulose in Performance for Different Applications?

When comparing HPMC and Methylcellulose, their performance varies greatly depending on the application. Let’s break it down to understand their strengths and weaknesses in specific industries.

In construction, HPMC is favored for its ability to enhance water retention and improve workability in products like mortars and tile adhesives. Its thickening properties help ensure consistency, making it easier for workers to apply the product.

Methylcellulose, however, excels in the food industry where it enhances texture and creates stable emulsions. For instance, in dairy-free products, Methylcellulose is used to mimic the mouthfeel and texture of traditional dairy, providing a comparable experience for consumers.

This is where it gets interesting… In the pharmaceutical industry, both compounds have their place. HPMC is typically used in controlled-release tablets due to its superior ability to control the dissolution rate. Methylcellulose is often used for its stabilizing properties in liquid formulations and suspensions.

| Application | Best Fit | Why It Works |

|---|---|---|

| Construction | HPMC | Water retention, thickening agent |

| Food & Beverage | Methylcellulose | Texture enhancement, emulsification |

| Pharmaceuticals | HPMC | Controlled release, binder, suspensions |

| Pharmaceuticals | Methylcellulose | Stabilizer in suspensions, viscosity |

6. What are the Benefits of Using HPMC Over Methylcellulose?

HPMC offers several benefits, particularly in industries requiring stable formulations and high viscosity. For instance, in construction, HPMC is essential for improving the adhesion of mortar and cement-based products. Its thickening properties ensure that the mixtures remain workable and don’t dry out too quickly.

In pharmaceuticals, HPMC is used for its excellent ability to control the dissolution rate of drugs. This means it can be used in controlled-release tablets, which slowly release medication over time, improving patient compliance and treatment outcomes.

Another benefit of HPMC is its environmental friendliness. It is biodegradable and does not have the same environmental impact as other synthetic materials. This makes it an attractive option for companies aiming to reduce their ecological footprint.

What’s the real kicker here? HPMC’s versatility and performance across multiple industries make it a preferred choice for many businesses looking for a reliable, high-quality material.

| Benefit | HPMC | Methylcellulose |

|---|---|---|

| Adhesion Properties | Improves workability | Less effective for adhesion |

| Dissolution Control | Controls release in tablets | Not as effective in release control |

| Environmental Impact | Biodegradable | Not as eco-friendly |

7. When Should You Choose Methylcellulose Over HPMC?

Methylcellulose is the superior choice in certain applications. For instance, if you are working in the food industry and require a compound that can form gels at lower temperatures, Methylcellulose is an excellent choice. It’s especially beneficial in plant-based food products where texture and mouthfeel are crucial.

In the cosmetics industry, Methylcellulose is preferred because of its ability to stabilize emulsions and improve the viscosity of lotions, shampoos, and conditioners. Its versatility allows for better control over product consistency, which is essential in personal care formulations.

Ready for the good part? Methylcellulose is also a go-to option for products that require vegan or natural ingredients. Its plant-derived nature appeals to a growing market of environmentally-conscious consumers.

| Application | Best Fit | Reason for Choice |

|---|---|---|

| Food & Beverage | Methylcellulose | Gel formation, texture enhancement |

| Cosmetics | Methylcellulose | Emulsion stabilization, viscosity |

| Plant-based Products | Methylcellulose | Vegan-friendly, natural ingredients |

8. Can You Substitute HPMC for Methylcellulose and Vice Versa?

While HPMC and Methylcellulose share some similarities, substitution is not always ideal. For instance, in food products where gel formation is required, Methylcellulose can’t always be replaced with HPMC due to their different solubility and gel-forming behaviors.

In pharmaceuticals, substituting HPMC with Methylcellulose might affect the controlled-release properties of certain tablets. Methylcellulose lacks the same dissolution control that HPMC offers, which could result in inconsistent drug release.

What’s the real story? Substitution may be possible in some cases, but it’s essential to carefully evaluate the needs of your product before making that decision. Always test formulations thoroughly to ensure performance is not compromised.

| Scenario | Can Substitute? | Considerations |

|---|---|---|

| Food Applications | No | Different gel-forming properties |

| Pharmaceutical Formulations | No | Controlled release properties needed |

| Cosmetics | Yes | Similar thickening effects |

9. How Do You Ensure the Best Quality and Performance for HPMC and Methylcellulose?

Ensuring the best quality starts with selecting a reputable supplier. Both HPMC and Methylcellulose must meet stringent quality control standards to ensure they perform as expected in their respective applications.

Look for manufacturers who provide clear testing procedures and compliance certificates. It’s crucial to verify that the compound meets industry standards such as USP, EP, or JP.

Another key factor is custom formulation. Some industries require specialized grades of HPMC or Methylcellulose, such as those with higher viscosity or specific solubility rates. Working with a supplier who offers technical support and the ability to customize the product will help ensure the best performance.

| Quality Factor | HPMC | Methylcellulose |

|---|---|---|

| Supplier Reputation | Important for quality assurance | Ensure consistent quality |

| Compliance Standards | USP, EP, JP compliance | Industry-standard testing |

| Custom Formulation | Tailored viscosity, solubility | Custom gel-forming properties |

10. What are the Future Trends for HPMC and Methylcellulose in Industry?

The demand for both HPMC and Methylcellulose is expected to grow as industries look for more sustainable and versatile ingredients. In the pharmaceutical industry, there’s a trend toward personalized medicine, which may increase the demand for specialized formulations using HPMC.

For food and cosmetics, there’s a shift towards natural, plant-based ingredients. Methylcellulose, being a plant-derived product, fits perfectly within this growing market.

This is where it gets interesting… As sustainability becomes a major factor for many industries, both HPMC and Methylcellulose will play a significant role in reducing environmental impact. More companies are opting for biodegradable materials, and cellulose derivatives provide an eco-friendly alternative to synthetic compounds.

| Industry | Trend | Impact on HPMC and Methylcellulose |

|---|---|---|

| Pharmaceuticals | Personalized medicine | Increased demand for specialized formulations |

| Food & Beverage | Plant-based, natural ingredients | Growth in demand for Methylcellulose |

| Cosmetics | Eco-friendly, sustainable products | More use of natural cellulose derivatives |

FAQ Section

Q1: What is HPMC?

HPMC (Hydroxypropyl Methylcellulose) is a cellulose-derived compound used as a thickening agent, binder, and stabilizer in various industries, including pharmaceuticals, food, and construction.

Q2: How does Methylcellulose work in food applications?

Methylcellulose is used in food processing for texture enhancement and emulsification. It forms gels when heated and is often used in plant-based products to mimic the texture of traditional dairy or meat.

Q3: Can HPMC be used in pharmaceutical tablet formulations?

Yes, HPMC is widely used in pharmaceutical formulations, particularly in controlled-release tablets, due to its ability to regulate drug release and improve the stability of the formulation.

Q4: What are the key differences between HPMC and Methylcellulose?

The primary differences between HPMC and Methylcellulose lie in their solubility, gel-forming abilities, and common uses. HPMC is commonly used in pharmaceuticals and construction, while Methylcellulose is more prevalent in food and cosmetic industries.

Q5: How do I choose the right cellulose derivative for my product?

Choosing between HPMC and Methylcellulose depends on your specific application needs. For thickening and water retention, HPMC is ideal. For gel formation and vegan-friendly formulations, Methylcellulose may be the better option.