Hydroxypropyl methylcellulose (HPMC) stands as a cornerstone ingredient across multiple industries, from pharmaceuticals to construction. This versatile cellulose derivative offers unique properties that make it indispensable for product developers and manufacturing professionals seeking reliable performance. If you’re responsible for material selection or formulation development, understanding HPMC’s key properties is essential for making informed decisions that impact product quality and performance. This article provides a comprehensive examination of HPMC’s fundamental characteristics, comparative advantages, and technical parameters to help you select the right grade for your specific application needs.

1. What Is Hydroxypropyl Methylcellulose And How Does It Work?

Hydroxypropyl methylcellulose is a semi-synthetic polymer derived from cellulose, modified with methoxyl and hydroxypropyl groups. These modifications transform ordinary cellulose into a versatile material with exceptional functionality.

Here’s what makes it special: HPMC’s chemical structure consists of a cellulose backbone with anhydroglucose units connected by β-1,4-glycosidic bonds. The hydroxyl groups on this backbone are partially substituted with methoxyl and hydroxypropyl groups, which dramatically alter the polymer’s behavior and functionality.

| Chemical Aspect | Description | Functional Impact |

|---|---|---|

| Base Structure | Cellulose backbone with anhydroglucose units | Provides structural integrity and film-forming ability |

| Primary Substituents | Methoxyl (-OCH₃) groups | Controls hydrophobicity and thermal gelation |

| Secondary Substituents | Hydroxypropyl (-OCH₂CH(OH)CH₃) groups | Enhances water solubility and surface activity |

| Degree of Substitution | Varies by grade (typically 1.2-2.0) | Determines solubility characteristics and application suitability |

The manufacturing process involves treating natural cellulose with alkali, followed by reactions with methyl chloride and propylene oxide under controlled conditions. By precisely controlling reaction conditions, manufacturers create different grades of HPMC with varying viscosities (5-100,000 mPa·s).

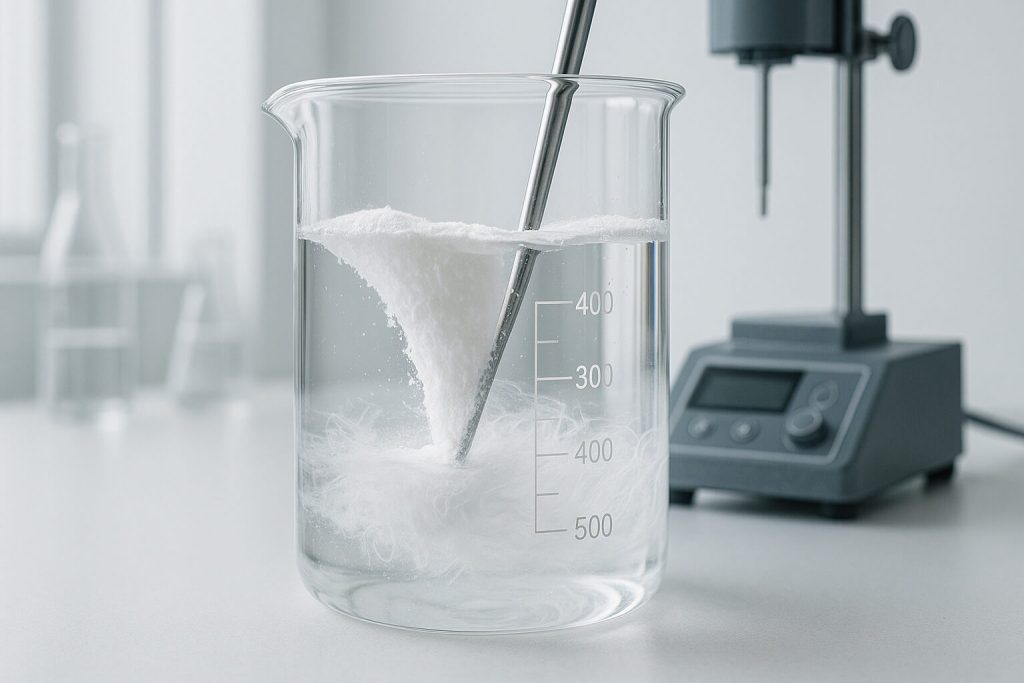

You might be wondering how HPMC functions in applications. Its core mechanisms include:

- Dissolving in cold water to form clear, viscous solutions

- Undergoing thermal gelation at specific temperatures

- Forming strong, flexible films upon drying

- Stabilizing suspensions and emulsions

- Binding particles together

- Retaining water in various formulations

When HPMC contacts water, it swells and dissolves to form a viscous solution. This hydration process is temperature-dependent—HPMC dissolves more readily in cold water than hot water, exhibiting “thermal gelation” or “reverse thermal gelation.”

2. What Makes HPMC Different From Other Cellulose Derivatives?

Let me be clear: HPMC’s distinctiveness lies in its specific chemical modification pattern. While all cellulose derivatives share the same basic backbone, the type, distribution, and degree of chemical substitution create significant functional differences.

| Cellulose Derivative | Chemical Substitution | Solubility Profile | Thermal Behavior | Key Applications |

|---|---|---|---|---|

| HPMC | Methoxyl + Hydroxypropyl | Cold water soluble, hot water gelling | Thermal gelation at 65-90°C | Pharmaceuticals, construction, food |

| MC | Methoxyl only | Cold water soluble, stronger thermal gelation | Thermal gelation at 50-55°C | Food, construction, personal care |

| CMC | Carboxymethyl | Soluble in cold/hot water, no thermal gelation | No thermal gelation | Food thickener, detergents, paper |

| HEC | Hydroxyethyl | Soluble in cold/hot water, no thermal gelation | No thermal gelation | Paints, personal care, oilfield |

The unique molecular characteristics of HPMC stem from the presence of both methoxyl and hydroxypropyl substituents. The methoxyl groups contribute hydrophobic properties, while the hydroxypropyl groups enhance water solubility and reduce surface tension. This dual modification creates a balanced amphiphilic character that other cellulose derivatives cannot match.

You’ll appreciate this fact: HPMC exhibits remarkable stability in the presence of enzymes, making it resistant to microbial degradation—particularly valuable in pharmaceutical applications where product stability is paramount.

HPMC’s unique combination of properties makes it particularly valuable in applications requiring:

- Controlled release of active ingredients

- Temperature-responsive behavior

- Film formation with specific permeability characteristics

- Stability in complex formulation environments

- Multifunctional performance (binding, thickening, and film formation in a single ingredient)

3. What Are The Physical Properties That Make HPMC Valuable?

What you need to know is this: HPMC’s solubility characteristics are among its most valuable attributes. Unlike many polymers, HPMC dissolves readily in cold water but exhibits “reverse solubility” or “thermal gelation” at higher temperatures.

| Solvent Type | HPMC Solubility | Practical Application |

|---|---|---|

| Cold Water (< 30°C) | Highly soluble | Primary dissolution medium for most applications |

| Hot Water (> 60-85°C) | Forms gel, reduced solubility | Controlled release systems, temperature-triggered applications |

| Ethanol/Water Mixtures | Soluble in specific ratios | Pharmaceutical coating systems, alcohol-containing formulations |

| Pure Organic Solvents | Generally insoluble | Can be used as release barrier in organic media |

HPMC is available in a wide range of viscosity grades (5-100,000 mPa·s), typically measured as a 2% aqueous solution at 20°C.

You might be surprised to learn that temperature has a complex effect on HPMC solution viscosity. At lower temperatures, viscosity decreases as temperature increases. However, at a critical temperature (typically 65-90°C), HPMC undergoes thermal gelation, transforming into a gel as hydrogen bonds between water and polymer are replaced by polymer-polymer interactions.

The film-forming capabilities of HPMC are particularly valuable in coating applications. When an HPMC solution dries, it forms a transparent, tough, and flexible film with excellent barrier properties, including:

- Good oxygen and grease barrier properties

- Moderate water vapor barrier properties

- Excellent tensile strength and flexibility

- Optical clarity and gloss

- Non-toxicity and biodegradability

The real value comes from HPMC’s ability to form films without plasticizers, though they can be added when needed. This simplifies formulations and reduces potential compatibility issues.

HPMC exhibits remarkable stability across a wide range of conditions:

- pH Stability: Stable across pH 3-11

- Temperature Stability: Stable during normal processing and storage

- Microbial Stability: Resistant to enzymatic degradation

- Light Stability: Does not yellow or degrade under normal light exposure

- Compatibility: Compatible with many salts, surfactants, and other ingredients

4. How Does HPMC Perform In Pharmaceutical Applications?

What makes this particularly valuable is HPMC’s ability to form hydrophilic matrix systems for controlled drug release. When a tablet containing HPMC contacts aqueous media, the polymer hydrates and forms a gel layer that controls the release rate of the active pharmaceutical ingredient.

| Release Phase | Dominant Mechanism | Rate-Controlling Factors | Duration |

|---|---|---|---|

| Initial Burst | Surface dissolution | API solubility, HPMC grade | First 30-60 minutes |

| Steady Release | Diffusion through gel layer | Gel viscosity, matrix thickness | 2-12 hours |

| Terminal Phase | Matrix erosion | HPMC molecular weight, concentration | Final 4-24 hours |

The versatility of HPMC in controlled release applications stems from the ability to tune release profiles by adjusting:

- HPMC viscosity grade (molecular weight)

- HPMC concentration in the formulation

- Substitution type (ratio of methoxyl to hydroxypropyl groups)

- Combination with other release-modifying excipients

You should know that HPMC’s non-ionic nature provides a significant advantage in pharmaceutical formulations. Unlike ionic polymers that can interact with charged drug molecules or be affected by pH changes in the gastrointestinal tract, HPMC maintains consistent performance across varying physiological conditions.

In tablet coating applications, HPMC offers exceptional functionality as a film-forming agent, providing:

- Moderate moisture protection for sensitive APIs

- Taste masking through continuous film barriers

- Aesthetic appearance with glossy, smooth finishes

- Process efficiency with good adhesion and low tackiness

- Stability through UV and oxygen barrier properties

The truth is that biocompatibility and regulatory considerations are paramount in pharmaceutical applications, and HPMC excels in this regard. HPMC is:

- Generally Recognized as Safe (GRAS) by the FDA

- Listed in major pharmacopeias (USP, Ph.Eur.)

- Non-toxic and non-irritating

- Free from animal-derived components

- Stable under normal storage conditions with a long shelf life

5. What Technical Parameters Should Be Considered When Selecting HPMC?

Here’s something crucial to understand: The substitution degree of HPMC is perhaps the most fundamental parameter affecting its performance. This refers to the extent to which hydroxyl groups on the cellulose backbone have been replaced with methoxyl and hydroxypropyl groups.

| Substitution Parameter | Typical Range | Impact on Performance |

|---|---|---|

| Methoxyl Content | 19-30% | Higher content increases organic solubility and lowers gelation temperature |

| Hydroxypropyl Content | 4-12% | Higher content increases water solubility and surface activity |

| Methoxyl/Hydroxypropyl Ratio | 2:1 to 6:1 | Determines balance between hydrophobic and hydrophilic properties |

| Total Substitution | 25-35% | Affects overall solubility profile and thermal behavior |

Different pharmacopeial grades of HPMC are classified based on their substitution pattern, such as HPMC 2208 (~22% methoxyl, ~8% hydroxypropyl) or HPMC 2910 (~29% methoxyl, ~10% hydroxypropyl).

You’ll find it interesting that the molecular weight of HPMC directly correlates with its viscosity in solution, which is why HPMC grades are often categorized by their viscosity. The relationship follows approximately a power law, where viscosity increases exponentially with molecular weight.

| Viscosity Range | Approximate Molecular Weight | Typical Applications |

|---|---|---|

| Low (5-50 mPa·s) | 10,000-65,000 Da | Film coating, binding in immediate release formulations |

| Medium (100-4,000 mPa·s) | 65,000-120,000 Da | Controlled release matrices, general purpose thickening |

| High (4,000-100,000 mPa·s) | 120,000-250,000 Da | Extended release systems, construction applications |

Particle size distribution is another critical parameter that affects HPMC performance, influencing:

- Dissolution rate and hydration kinetics

- Flow properties and handling characteristics

- Dispersion uniformity in dry blends

- Surface area and reactivity

The reality is that quality control specifications for HPMC are rigorous and comprehensive, ensuring consistent performance across batches. Key quality parameters typically include identification tests, substitution degree, viscosity, loss on drying, residual solvents, heavy metals content, microbial limits, and pH of aqueous solution.

6. How Is HPMC Applied In Construction And Building Materials?

What you need to realize is that HPMC plays a crucial role in cement-based products by modifying their rheological properties. When added to cement mixtures, HPMC creates a more cohesive, workable material that’s easier to apply and finish.

| Function | Mechanism | Benefit to Construction |

|---|---|---|

| Water Retention | Forms hydrogen bonds with water molecules | Prevents premature drying, ensures proper cement hydration |

| Workability Enhancement | Increases viscosity and lubrication | Improves application properties, reduces labor requirements |

| Sag Resistance | Creates thixotropic behavior | Enables thicker application on vertical surfaces without slumping |

| Open Time Extension | Slows water evaporation | Provides longer working time for proper application and finishing |

| Air Entrainment | Stabilizes tiny air bubbles | Improves freeze-thaw resistance and workability |

Here’s something fascinating: HPMC can retain up to 10 times its weight in water, significantly extending the open time of mortars and allowing for proper application even in challenging conditions like high temperatures or absorbent substrates.

Workability improvement is another significant benefit HPMC brings to construction materials. By increasing the viscosity of the water phase and providing lubrication between solid particles, HPMC:

- Reduces the amount of water needed for proper consistency

- Improves spreadability and ease of application

- Prevents segregation of components during mixing and application

- Enhances pumpability for machine-applied systems

- Reduces friction between trowel and material for smoother finishing

The bottom line is HPMC’s adhesion enhancement properties make it invaluable in specialized construction applications like tile adhesives and renders. HPMC increases the bond strength between the mortar and substrate by improving wetting, creating mechanical interlocking, enhancing polymer film formation, reducing shrinkage stresses, and promoting more complete cement hydration at the bond line.

By ensuring proper cement hydration and reducing water demand, HPMC helps create stronger, more durable building materials with improved compressive and flexural strength, enhanced freeze-thaw resistance, reduced shrinkage and cracking, better water penetration resistance, and improved durability under varying environmental conditions.

Conclusion

Hydroxypropyl methylcellulose stands as a remarkably versatile polymer with properties that make it indispensable across multiple industries. Throughout this article, we’ve explored the fundamental characteristics that make HPMC such a valuable material for product developers and manufacturing professionals. From its unique chemical structure and modification patterns to its exceptional physical properties and performance in various applications, HPMC offers solutions to numerous formulation challenges.

The ability of HPMC to form viscous solutions, undergo thermal gelation, create strong flexible films, and retain water makes it particularly valuable in pharmaceutical, food, and construction applications. Its non-ionic nature, stability across a wide pH range, and compatibility with numerous ingredients further enhance its utility in complex formulations.

When selecting the appropriate HPMC grade for your specific application, remember to consider key technical parameters including substitution degree, molecular weight, viscosity, and particle size distribution. These factors will determine how the material performs in your formulation and ultimately impact the quality of your finished product.

For further assistance with HPMC selection or application, consider consulting with technical experts from reputable suppliers who can provide guidance tailored to your specific needs.

FAQ Section

Q1: What is the difference between HPMC and HPMC-AS?

HPMC (Hydroxypropyl methylcellulose) and HPMC-AS (Hydroxypropyl methylcellulose acetate succinate) are related polymers with distinct chemical structures and applications. HPMC is a non-ionic cellulose ether with methoxyl and hydroxypropyl substituents, offering pH-independent solubility. HPMC-AS contains additional acetyl and succinoyl groups that make it pH-dependent in solubility—insoluble in acidic environments (stomach) but soluble in higher pH environments (intestines). This makes HPMC-AS valuable for enteric coating and targeted intestinal drug delivery, whereas HPMC is more versatile across various applications.

Q2: How does temperature affect the viscosity of HPMC solutions?

Temperature has a unique effect on HPMC solutions. At lower temperatures (below 50°C), viscosity decreases as temperature increases. However, HPMC exhibits “thermal gelation” at higher temperatures. When an HPMC solution reaches its critical temperature (65-90°C, depending on grade), the polymer chains dehydrate as hydrogen bonds between water and polymer break, leading to polymer-polymer associations and gel formation. This causes a sharp viscosity increase and gelation. This behavior is fully reversible—upon cooling, the gel reverts to a solution state, making HPMC valuable in applications requiring temperature-triggered viscosity changes.

Q3: Can HPMC be used in food products, and what grades are suitable?

Yes, HPMC is widely used in food products as additive E464 in Europe and as GRAS (Generally Recognized As Safe) by the FDA. Food-grade HPMC must meet specific purity requirements with controlled levels of heavy metals, residual solvents, and microbial contamination. In foods, HPMC serves as a thickener, stabilizer, emulsifier, and film-former. It’s used in gluten-free baked goods to improve texture, in fried foods to reduce oil absorption, in ice creams to prevent ice crystal formation, and in sauces as a stabilizer. Manufacturers should choose grades specifically marketed for food use with appropriate regulatory documentation.

Q4: What are the recommended storage conditions for HPMC powder?

HPMC powder should be stored in cool, dry environments (10-30°C/50-86°F) with relative humidity below 60%. Being hygroscopic, HPMC can absorb moisture, leading to clumping and reduced flow properties. Original packaging should remain sealed until use, and opened containers should be tightly resealed. Protect from direct sunlight and heat sources. Typical shelf life is 2-3 years when properly stored. Suitable packaging includes multi-layer paper bags with polyethylene liners or fiber drums that provide moisture barriers. Regular inspection for clumping is recommended for material stored long-term.

Q5: How does the substitution pattern of HPMC affect its solubility?

The substitution pattern—specifically the ratio and distribution of methoxyl and hydroxypropyl groups—significantly influences HPMC’s solubility. Higher methoxyl content increases hydrophobic character, enhancing organic solubility while reducing cold water solubility. Higher hydroxypropyl content increases hydrophilic nature, improving cold water solubility and reducing thermal gelation temperature. More uniform substitution typically results in better solubility. HPMC grades with methoxyl content around 28-30% and hydroxypropyl content of 7-12% (USP type 2910) offer excellent water solubility while maintaining good organic solubility. This relationship allows manufacturers to select or customize HPMC grades for specific application requirements.