When discussing the solubility of Hydroxypropyl Methylcellulose (HPMC), understanding the best practices can significantly affect the formulation’s effectiveness across various applications. This article will delve into important tips for HPMC solubility, focusing on key factors that influence its behavior in organic solvents. With practical solutions that benefit pharmaceutical, food, and cosmetic sectors, this discussion aims to equip decision-makers with the knowledge needed to enhance product quality and efficiency. Let’s explore these tips and their implications for professional settings, from optimizing solvent selection to understanding molecular weight.

1. What Is HPMC and Why Is It Important?

HPMC, or Hydroxypropyl Methylcellulose, is a cellulose-derived polymer known for its versatility. What’s the real story? HPMC is widely recognized for its applications across several industries, including pharmaceuticals, food products, and personal care items. In the pharmaceutical sector, HPMC serves as an essential excipient used in tablet formulations and drug delivery systems. Its ability to form gels and modulate release rates makes it indispensable for creating controlled-release medications.

In the food industry, HPMC acts as a thickener and stabilizer. It improves texture and consistency in low-calorie food products, appealing to consumers looking for healthier options. In cosmetics, HPMC helps create emulsions, ensuring a smooth and non-greasy feel, which enhances consumer experience.

The importance of HPMC extends beyond its functionality; understanding its solubility is crucial for achieving the desired results in formulations. The behavior of HPMC in different solvents can determine the product’s overall effectiveness, stability, and consumer satisfaction. For instance, solubility affects the viscosity of solutions, which in turn influences how well products perform in various applications.

In summary, HPMC is vital for countless formulations, and knowing its characteristics—especially solubility—helps professionals make informed decisions in product development. This understanding is essential for maintaining quality and meeting market demands.

| Application Sector | Importance of HPMC |

|---|---|

| Pharmaceuticals | Excipient in drug formulations for controlled release |

| Food Industry | Thickening agent for low-calorie products |

| Personal Care | Emulsifier for smooth and stable cosmetics |

2. What Are the Key Factors Affecting HPMC Solubility?

The solubility of HPMC in organic solvents hinges on several key factors, each playing a distinct role in formulation effectiveness. Ready for the good part? Understanding these factors can help you optimize product development.

First and foremost, solvent polarity is crucial. HPMC tends to dissolve better in polar solvents compared to non-polar ones. For instance, solvents like ethanol and methanol are effective in dissolving HPMC, allowing for uniformity in mixtures. In contrast, non-polar solvents like hexane may hinder solubility, leading to separation or inconsistent formulations.

Temperature also significantly influences solubility. Increasing the temperature usually enhances the solubility of HPMC, which accelerates the dissolution process. For example, during manufacturing, pre-heating solvents can substantially reduce mixing time and improve the overall efficiency of the formulation process.

Another vital factor is the pH of the solvent. Extreme pH levels can lead to changes in the molecular structure of HPMC, affecting its ability to dissolve. It’s imperative to maintain an optimal pH range that preserves HPMC’s integrity and functional properties.

In conclusion, these factors collectively determine the effectiveness of HPMC in formulations. By keeping solvent polarity, temperature, and pH in check, formulators can significantly enhance product quality and performance.

| Factor | Description |

|---|---|

| Solvent Polarity | Higher solubility in polar solvents |

| Temperature | Increased temperature enhances dissolution rates |

| pH Levels | Extreme pH can impact HPMC’s solubility |

3. How Do You Select the Right Solvent for HPMC?

Selecting the right solvent for HPMC is a critical step in formulation development. But here’s the kicker: not all solvents are created equal. Each one can yield different results when mixed with HPMC, impacting the final product’s quality.

When considering the choice of solvent, one must evaluate the polarity of the solvent. As mentioned earlier, polar solvents such as ethanol, methanol, and isopropanol provide better dissolution properties. Ethanol, for instance, is often favored not only for its effective solubility but also for its widespread acceptance in many industries, including pharmaceuticals and food.

Another crucial aspect is the specific application. For formulations intended for fast-acting effects, a solvent that dissolves HPMC quickly, like methanol, can be preferable. Conversely, if the goal is to create a thicker product for cosmetic applications, a more viscous solvent may be necessary.

It’s also essential to consider regulatory compliance and safety. Certain solvents may pose health risks or fall under stricter regulations. Therefore, choosing a safer, less volatile solvent can align with both safety requirements and consumer expectations.

Evaluating these criteria ensures that the selected solvent complements the role of HPMC in the formulation while delivering the desired product characteristics.

| Solvent Type | Key Properties |

|---|---|

| Ethanol | Good solubility, widely accepted |

| Methanol | Fast-dissolving, suitable for quick-release |

| Isopropanol | Effective for cosmetic applications |

4. What Is the Importance of HPMC Molecular Weight in Solubility?

The molecular weight of HPMC significantly influences its solubility in organic solvents. What’s the key takeaway? Understanding how molecular weight affects solubility can optimize product development across various applications.

HPMC is available in a range of molecular weights, from low to high. Lower molecular weight grades dissolve quickly and are ideal for formulations that require rapid release, such as in immediate-release tablets. This quick solubility can greatly enhance the efficacy of pharmaceutical products by ensuring that the active ingredients are readily available.

On the other hand, high molecular weight HPMC grades offer advantages in applications where a thicker, viscous solution is required. For example, in sustained-release formulations, high molecular weight HPMC forms gels that retain the active ingredient, controlling the release rate over time. This quality is crucial in designing medications that ensure prolonged therapeutic effects.

However, it’s essential to recognize that higher molecular weight HPMC grades may take longer to dissolve, presenting challenges in formulation processes. Therefore, formulators must carefully select the appropriate molecular weight depending on the intended application and desired performance.

In summary, the choice of HPMC molecular weight affects not only solubility but also the overall functionality of the final product. Balancing these characteristics is vital for creating effective formulations that meet market demands.

| Molecular Weight | Application Implications |

|---|---|

| Low Molecular Weight | Quick dissolution, good for immediate release |

| Medium Molecular Weight | Balanced properties for various applications |

| High Molecular Weight | Provides viscosity, suitable for sustained release |

5. How Can You Effectively Test HPMC Solubility in Organic Solvents?

Testing HPMC solubility in organic solvents requires a systematic approach. Are you ready for the good part? Following a well-defined protocol ensures accurate and reliable results.

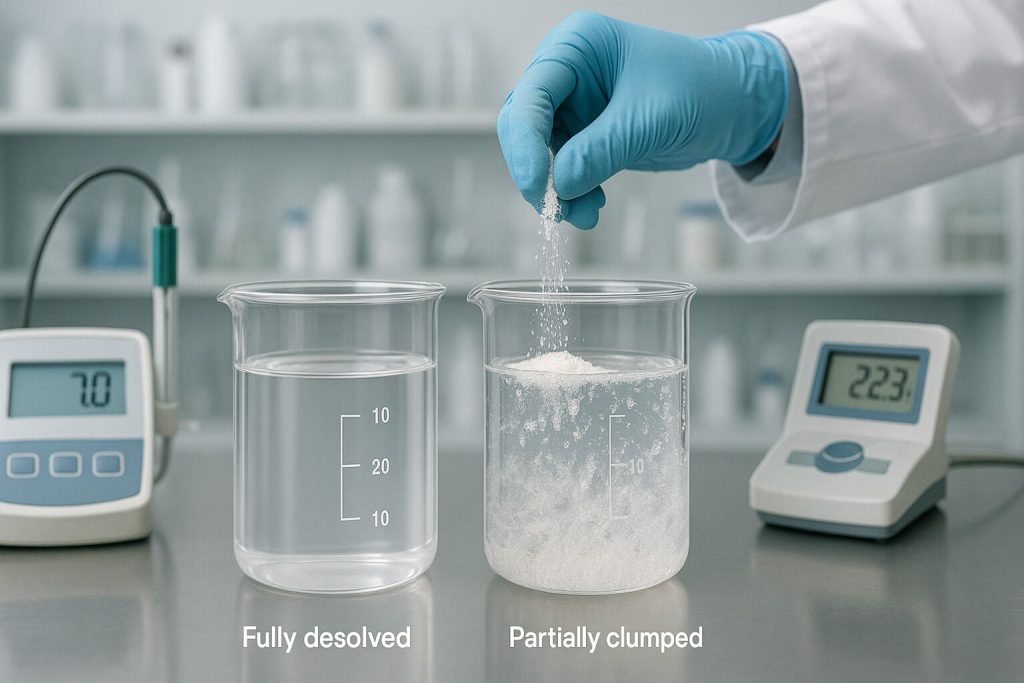

Begin your solubility testing by selecting multiple HPMC grades. This selection provides an understanding of how each grade performs in various solvents. Prepare a series of test solutions by dissolving a specific amount of HPMC in chosen solvents, varying temperature and agitation for better results.

Temperature control is vital during testing. Utilizing a water bath can maintain a consistent temperature throughout the test, ensuring that solubility results are not skewed by fluctuating conditions. Stir the solution continuously to promote uniform dissolution and reduce settling.

After a predetermined time, visually examine the solutions for clarity. The absence of undissolved particles indicates successful solubility. For a more quantitative assessment, spectrophotometric analysis can measure the concentration of HPMC in the solution, providing precise data.

Documenting the results, including HPMC grade, solvent type, and specific conditions during testing, allows for later analysis. This systematic testing approach not only clarifies the solubility characteristics but also helps troubleshoot potential challenges in formulation.

In conclusion, effectively testing HPMC solubility is critical for ensuring that formulations meet desired characteristics and performance.

| Testing Parameter | Recommended Approach |

|---|---|

| Select HPMC Grades | Use various molecular weights for comprehensive data |

| Controlled Mixing | Maintain consistent stirring and temperature |

| Visual Inspection | Observe clarity and presence of undissolved particles |

6. What Are Typical Applications of HPMC in Solvent-Based Formulations?

HPMC’s versatility extends into numerous applications, particularly in solvent-based formulations. What’s the real story? Understanding these applications can help formulate high-quality products.

In the pharmaceutical industry, HPMC is widely employed in controlled-release drug formulations. Its ability to form gels allows for the sustained release of active ingredients over time. For example, many extended-release tablets utilize high molecular weight HPMC to ensure that medication is gradually released, improving therapeutic outcomes and patient compliance.

The food industry also reaps the benefits of HPMC. It acts as a thickener in sauces, gravies, and gluten-free products, allowing manufacturers to create appealing textures that enhance eating experiences while keeping products low in calories. HPMC’s emulsifying properties enable stable mixtures in food products, preventing ingredient separation and maintaining a consistent appearance.

Apart from pharmaceuticals and food, HPMC finds valuable applications in personal care products. It is used in lotions and creams to stabilize emulsions, ensuring that oil and water components blend effectively. HPMC not only improves the sensory attributes of these products but also extends their shelf life by maintaining product integrity.

In essence, HPMC is indispensable across diverse industries due to its unique properties, showcasing how it enhances formulation quality and consumer appeal.

| Application Sector | Example Products |

|---|---|

| Pharmaceuticals | Controlled-release tablets |

| Food Industry | Thickening agent in sauces and gluten-free products |

| Personal Care | Emulsifier in creams and lotions |

7. What Are the Safety Considerations When Using HPMC?

Safety is paramount when utilizing HPMC in formulations. But here’s the kicker: understanding safety guidelines can prevent potential issues in production.

First, it is crucial to review the safety data sheets associated with HPMC and any organic solvents being used. While HPMC is generally regarded as safe (GRAS) by the FDA, safety may vary with different solvents. Certain organic solvents pose health risks, including toxicity concerns, and could impact worker safety if not handled properly.

Implementing best practices in handling and storage is fundamental. Personal protective equipment (PPE) should be utilized to minimize exposure, including gloves, masks, and goggles, especially in large production environments. Proper ventilation during mixing processes also plays a vital role in ensuring safety by dispersing any potentially harmful fumes.

Regular training for all personnel involved in the formulation process is essential. This training should cover the hazards associated with HPMC and the solvents used, outlining emergency procedures to follow in case of accidental exposure or spillage.

By prioritizing safety, manufacturers can not only protect workers but also ensure that the final products are safe for consumers, mitigating risks associated with ingredient use.

| Safety Consideration | Recommended Action |

|---|---|

| Toxicity Assessment | Review safety data sheets for HPMC and solvents |

| Proper Handling Procedures | Use PPE and ensure adequate ventilation |

| Personnel Training | Train staff on safety protocols and emergency response |

8. How Can Understanding HPMC Solubility Enhance Formulation Efficiency?

Knowledge about HPMC solubility can tremendously enhance formulation efficiency. What’s the key takeaway? By recognizing how solubility impacts product characteristics, formulators can create more effective and user-friendly products.

When HPMC dissolves properly, it ensures that formulations achieve the desired viscosity and texture. This characteristic is vital in applications such as pharmaceuticals, where a smooth consistency can improve swallowability in tablets and capsules. The right solubility profile directly affects how quickly a product can be produced and how well it performs.

In the food industry, controlling viscosity linked to HPMC solubility improves consumer experience. Products with optimal consistency and texture are more appealing to customers, and understanding how to achieve this through effective solvent selection streamlines production while ensuring quality.

Moreover, formulating products with ideal solubility characteristics minimizes wasted resources. When HPMC dissolves efficiently, it reduces the time and materials spent on troubleshooting solubility problems. This not only enhances product quality but also boosts operational efficiency.

In summary, grasping the nuances of HPMC solubility is key to improving overall formulation processes, resulting in better products that appeal to consumers and meet market demands.

| Efficiency Aspect | Impact of HPMC Solubility |

|---|---|

| Viscosity Control | Achieves desired texture and consistency |

| Production Time | Reduces time spent on troubleshooting |

| Resource Management | Minimizes material waste during formulation |

9. What Recent Trends Affect HPMC Utilization in Industrial Applications?

The usage of HPMC in industrial applications is influenced by several recent trends. Ready for the good part? Recognizing these trends can help companies adapt and thrive in competitive markets.

One notable trend is the increasing demand for clean-label products. Consumers are more vigilant about ingredient transparency and safety, leading manufacturers to opt for safe, natural ingredients like HPMC. This shift pushes companies to ensure their formulations utilize HPMC effectively, showcasing its benefits while aligning with consumer preferences.

Sustainability is another crucial influencing factor. Companies are striving to adopt more environmentally friendly practices, including sourcing sustainable ingredients and utilizing greener solvents. Research is ongoing into developing eco-friendly alternatives to traditional solvents, promoting not only product quality but also reducing environmental impact.

Technological innovations also play a role. Advancements in formulation technology allow for more precise control of solubility and product characteristics. These innovations enable formulators to create new product lines that were unattainable with previous methods, unlocking new opportunities in various industries.

Understanding these trends is necessary for businesses as they navigate an ever-evolving market landscape. By being aware of changing consumer preferences and technological advancements, companies can leverage HPMC’s benefits for their formulations and maintain a competitive edge.

| Trend | Implications for HPMC Use |

|---|---|

| Clean-label Consumer Demand | Drives the need for transparent and safe ingredients |

| Sustainability | Encourages eco-friendly formulation practices |

| Technological Innovations | Enables precise control and new product developments |

10. Where Can You Find Reliable Resources on HPMC Solubility?

Finding reliable resources for HPMC solubility is crucial for professionals involved in formulation development. What’s the real story? Accessing trustworthy information can significantly impact the effectiveness of your formulations.

One of the best starting points is reputable suppliers and manufacturers of HPMC. Many industry leaders provide detailed technical data sheets that include solubility characteristics in various organic solvents, along with practical usage guidelines. These documents are invaluable for formulators seeking reliable information to inform their choices.

Additionally, industry publications and databases offer a wealth of knowledge regarding the properties and applications of HPMC. Journals such as the “International Journal of Pharmaceutics” frequently publish research articles that delve into the latest findings concerning solubility and formulation techniques.

Industry conferences can also present excellent networking opportunities for learning about new technologies and methods involving HPMC. Engaging with peers and experts can help you stay informed about trends and advancements in the field.

Lastly, joining professional organizations in related sectors can help you access specialized resources, including research articles and technical reports.

By leveraging these resources, formulators can enhance their understanding of HPMC’s solubility and optimize their products for better performance.

| Resource Type | Description |

|---|---|

| Reputable Suppliers | Provide technical data sheets on HPMC |

| Journals and Databases | Offer research articles on HPMC properties |

| Industry Conferences | Facilitate networking and learning opportunities |

FAQ Section

Q1: What is HPMC?

HPMC (Hydroxypropyl Methylcellulose) is a cellulose-derived polymer used as a thickening, binding, and emulsifying agent across various applications.

Q2: How does HPMC solubility work in organic solvents?

HPMC solubility is influenced by factors such as solvent polarity, temperature, and pH, determining its performance in formulations.

Q3: What is the significance of molecular weight in HPMC solubility?

The molecular weight of HPMC affects solubility rates and viscosity, impacting its application in different formulations.

Q4: What safety measures should be taken when handling HPMC?

It is essential to review safety data sheets, use appropriate PPE, and ensure proper ventilation when working with HPMC and solvents.

Q5: How can you test the solubility of HPMC effectively?

Testing HPMC solubility involves preparing solutions under controlled conditions and observing dissolution rates and clarity.