Introduction

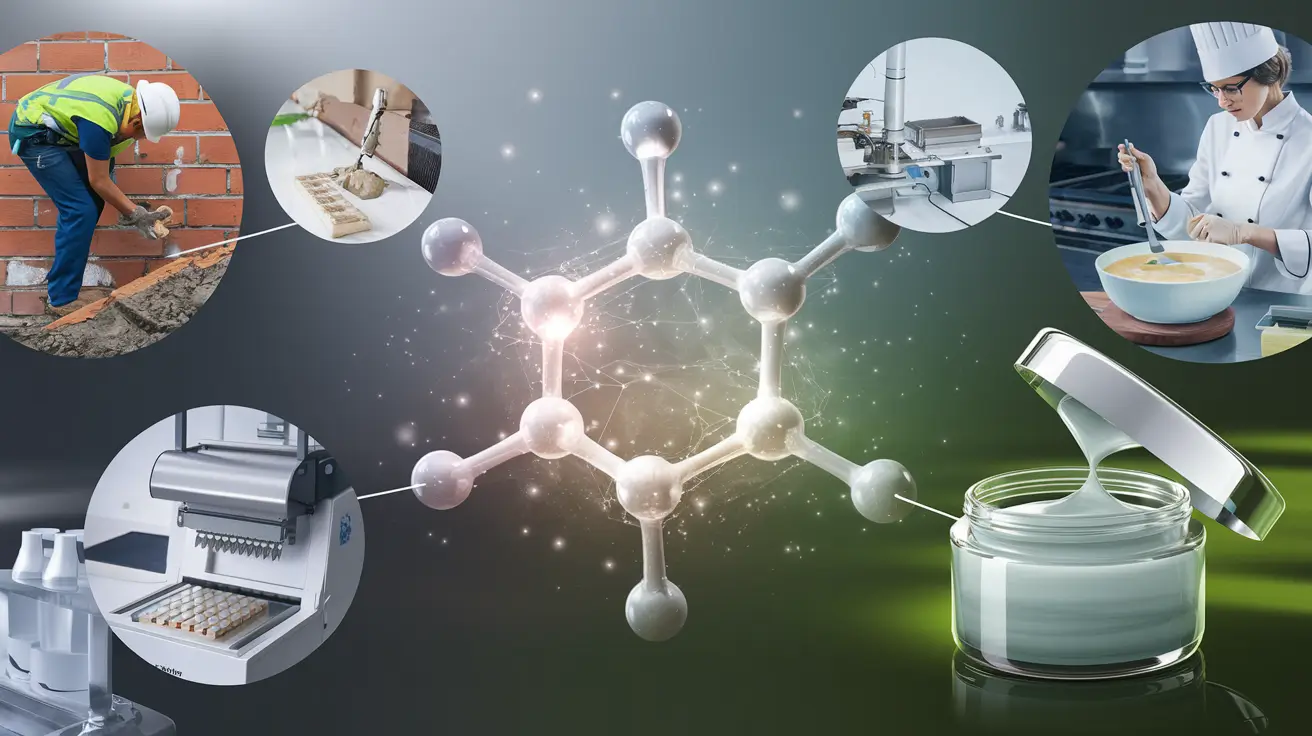

In today’s industrial landscape, where precision and performance are paramount, Hydroxypropyl Methylcellulose (HPMC) has established itself as a game-changing material. This versatile compound supports innovation across industries such as construction, pharmaceuticals, and cosmetics, delivering enhanced functionality and superior results. HPMC improves the workability of cement, enables controlled drug release, and stabilizes emulsions, cementing its role as a cornerstone of modern manufacturing.

Yet, the value of HPMC is only as strong as the quality behind it. Achieving consistent, high-performance outcomes relies on the expertise, advanced technology, and unwavering standards of its manufacturer. For industries that depend on reliability, choosing the right HPMC supplier can mean the difference between operational success and costly setbacks.

What truly defines a standout HPMC manufacturer? Is it their state-of-the-art facilities, ability to tailor formulations to specific needs, or strict compliance with international standards? Let’s explore the core attributes of exceptional HPMC production and uncover the key benchmarks that separate the best from the rest. The insights might surprise you.

What Is Hydroxypropyl Methylcellulose (HPMC)?

Hydroxypropyl Methylcellulose (HPMC) is a highly versatile cellulose ether derived from natural plant fibers. Through an advanced chemical modification process involving methyl chloride and propylene oxide, these fibers are transformed into a white, odorless, water-soluble powder with excellent film-forming properties. Its unique chemical structure, combining hydrophilic and hydrophobic elements, enables its broad applicability across numerous industries.

The true strength of HPMC lies in its adaptability. Acting as a thickener, stabilizer, binder, and film-former, it meets the diverse needs of various sectors. In construction, HPMC enhances the workability, adhesion, and water retention of cement-based materials and dry-mix mortars. In the pharmaceutical industry, it is integral to tablet coatings, controlled-release drug formulations, and as a plant-based alternative to gelatin in capsules. For the food industry, it serves as an effective stabilizer and emulsifier, while in cosmetics, it provides smooth textures and ensures product stability.

What gives HPMC its remarkable versatility and environmentally friendly profile? By diving deeper into its chemical properties, we can uncover why it has become a cornerstone material across so many industries.

Why Is Choosing a Reliable HPMC Manufacturer Crucial?

The quality of Hydroxypropyl Methylcellulose (HPMC) is far more than a technical consideration—it serves as the foundation for performance in industries where precision and consistency are paramount. High-quality HPMC delivers critical functionality, whether it’s improving the adhesion and water retention of tile adhesives, ensuring the efficacy of controlled-release pharmaceuticals, or stabilizing emulsions in food production. When manufactured to rigorous standards, HPMC ensures not only exceptional product performance but also safety and customer satisfaction.

Conversely, the consequences of using subpar HPMC can be severe. Inconsistent viscosity, contamination, or poor solubility can disrupt production processes, lead to costly delays, and even result in product failures or recalls. Consider the implications of a mortar that cracks prematurely or a pharmaceutical tablet that fails to release its active ingredient properly—these issues can damage reputations, erode customer trust, and generate significant financial losses.

How can you ensure your HPMC supplier meets these exacting demands? It starts with recognizing the key attributes of a manufacturer committed to quality and reliability. Let’s explore what sets the best apart.

What Are the Key Characteristics of a High-Quality HPMC Manufacturer?

Superior Production Processes

A high-quality HPMC manufacturer leverages cutting-edge production technologies to achieve precision and consistency in every batch. Advanced equipment and tightly controlled processes ensure uniform particle size distribution, stable viscosity levels, and optimal chemical properties. This level of control is crucial for applications that demand reliability, from smooth mortar applications in construction to precise drug delivery in pharmaceuticals. Consistency isn’t just a goal—it’s the foundation of exceptional HPMC production.

Commitment to Product Purity

Purity is critical, especially for HPMC used in pharmaceuticals and food products. Top-tier manufacturers implement advanced purification methods to reduce heavy metal content and eliminate contaminants, ensuring products exceed regulatory safety standards. This attention to purity provides peace of mind for customers who rely on HPMC in applications like tablet coatings and food stabilizers, where safety and quality are non-negotiable.

Customization Capabilities

An exceptional HPMC manufacturer recognizes the importance of tailoring products to meet specific industry needs. By offering customizable substitution levels for methoxyl and hydroxypropyl groups, they enable customers to achieve desired viscosity, water retention, and film-forming properties. This ability to create bespoke formulations empowers industries like construction, pharmaceuticals, and personal care to innovate and optimize performance.

Certifications and Compliance

Beyond technical capabilities, leading manufacturers adhere to globally recognized standards such as ISO certifications and GMP (Good Manufacturing Practices). These certifications serve as benchmarks for safety, quality, and environmental responsibility, assuring customers that their supplier is committed to excellence.

Strong Technical Support

A reliable HPMC manufacturer provides robust technical support, assisting clients with formulation challenges and ensuring the seamless integration of their products into various applications. This partnership approach helps customers maximize the performance and efficiency of their end products.

Selecting an HPMC manufacturer with these qualities is the key to securing consistent quality, innovative solutions, and long-term success.

How Do High-Quality Manufacturers Ensure Consistency?

Consistency is the defining attribute of a reputable HPMC manufacturer and the key to building trust with customers. Achieving this level of reliability requires a systematic approach to quality control at every stage of the production process. From selecting premium raw materials to the precise packaging of the final product, every step is closely monitored to ensure uniformity across batches. This meticulous attention to detail reduces variability and guarantees dependable performance.

Advanced testing methods are central to maintaining consistency. State-of-the-art equipment is employed to analyze critical parameters such as viscosity, particle size, purity, and chemical composition. These precision tools allow manufacturers to identify and address even the smallest discrepancies before products reach the market. By combining technology with expertise, manufacturers ensure that every batch meets the exact specifications required for optimal performance.

Additionally, adherence to globally recognized certifications like ISO 9001[^1] (Quality Management Systems) and ISO 14001 (Environmental Management Systems) underscores a manufacturer’s dedication to quality, environmental responsibility, and continuous improvement. These certifications provide customers with confidence that their supplier operates under strict protocols and is committed to maintaining the highest standards.

What does this consistency mean for businesses? It ensures reliable performance, fewer production disruptions, and greater customer satisfaction—ultimately leading to a competitive advantage in the market. Let’s examine how these benefits impact industries in practice.

[^1]: Understanding the significance of ISO certifications can help businesses ensure their suppliers meet international quality and environmental standards.

What Certifications Should a Reliable HPMC Manufacturer Have?

Certifications serve as a clear indicator of a manufacturer’s commitment to quality, safety, and compliance with global standards. For HPMC manufacturers, several key certifications ensure both product excellence and operational integrity.

ISO Certifications

ISO 9001 certification demonstrates that the manufacturer has established a robust quality management system, ensuring consistent production and customer satisfaction. ISO 14001 highlights the manufacturer’s dedication to environmental sustainability, ensuring eco-friendly production practices. These certifications provide assurance that the HPMC is produced with precision and responsibility, meeting global benchmarks for quality and sustainability.

Pharmaceutical and Food Safety Certifications

For industries like pharmaceuticals and food processing, certifications from regulatory bodies such as the FDA and compliance with EU regulations are essential. These approvals guarantee that the HPMC meets the highest standards of purity, safety, and functionality. Whether it’s for tablet coatings or food stabilizers, these certifications are crucial for ensuring product efficacy and consumer safety.

Chemical and Trade Compliance

Adherence to REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) and similar international chemical regulations is another vital certification for HPMC manufacturers. REACH compliance ensures that the products are free from hazardous substances, safe for use, and meet regulatory standards, facilitating hassle-free trade across global markets.

GMP Certification

Good Manufacturing Practices (GMP) certification, particularly relevant for pharmaceutical-grade HPMC, underscores a manufacturer’s ability to produce materials under controlled conditions, ensuring consistency, traceability, and adherence to strict hygiene standards.

Halal and Kosher Certifications

For manufacturers catering to the food and pharmaceutical industries, Halal and Kosher certifications are increasingly important. These certifications expand market access by meeting specific dietary and religious requirements.

The Real-World Benefits

Certifications not only verify the quality and safety of HPMC products but also strengthen businesses by fostering trust with clients, opening doors to global markets, and reducing compliance risks. By partnering with a certified manufacturer, businesses can confidently deliver high-performing products while reinforcing their reputation for excellence.

How Do They Address Sustainability?

Sustainability has evolved into a core expectation for modern manufacturing, and high-quality HPMC producers are rising to the challenge by integrating eco-friendly practices into every facet of their operations. These manufacturers prioritize reducing environmental impact while maintaining the exceptional product quality their customers rely on.

Renewable Raw Materials

The foundation of sustainability starts with sourcing. Leading HPMC manufacturers use renewable plant-based fibers as their primary raw material. By relying on sustainable forestry or agricultural practices, they reduce the strain on non-renewable resources and ensure a steady, environmentally responsible supply chain.

Recycling and Waste Management

Effective recycling and waste management systems are key to sustainable operations. By repurposing production by-products and minimizing waste sent to landfills, these manufacturers create closed-loop systems that conserve resources and reduce their environmental footprint. Some even collaborate with partners to recycle and reuse packaging materials, further extending their sustainability efforts.

Energy Efficiency and Carbon Reduction

Reducing energy consumption and greenhouse gas emissions is a priority for top manufacturers. They adopt energy-efficient technologies, utilize renewable energy sources like solar or wind, and implement low-emission production techniques. Optimizing logistics for transportation further reduces carbon emissions, ensuring sustainability across the supply chain.

Water Conservation

For an industry reliant on water during processing, responsible water management is critical. High-quality manufacturers employ advanced water recycling systems and adopt techniques that minimize water usage, ensuring this essential resource is conserved.

The Value for Customers

Sustainability goes beyond environmental ethics—it delivers real benefits to customers. Partnering with a sustainable HPMC manufacturer enhances a business’s green credentials, strengthens brand reputation, and appeals to eco-conscious consumers. Moreover, streamlined, resource-efficient production processes often translate into cost savings, creating a win-win scenario for manufacturers, businesses, and the planet alike.

By choosing a sustainable HPMC manufacturer, businesses can contribute to a cleaner future while securing reliable, high-quality materials for their operations.

What Sets Their Customer Support Apart?

Exceptional customer support is a defining feature of high-quality HPMC manufacturers. It reflects their commitment to building strong, long-term partnerships with clients by prioritizing responsiveness, expertise, and reliability.

Clear and Responsive Communication

High-quality manufacturers maintain efficient communication channels to address customer inquiries with speed and accuracy. Whether clients need detailed product specifications, assistance with formulations, or troubleshooting support, these manufacturers provide timely responses via email, phone, or online platforms. Clear communication minimizes misunderstandings, ensures smooth collaborations, and builds trust.

Technical Expertise and Tailored Guidance

Top manufacturers don’t just sell HPMC—they act as technical partners. They leverage their deep industry knowledge to provide customized guidance for specific applications. For instance, they help construction companies optimize mortar formulations for improved workability and adhesion or assist pharmaceutical firms in achieving precise controlled-release profiles for tablets. This consultative approach adds significant value, empowering customers to maximize the performance of their products.

Reliable Logistics and On-Time Deliveries

In industries where production schedules are tightly linked to supply chains, timely delivery is non-negotiable. Leading HPMC manufacturers excel in logistics, offering flexible shipping options and ensuring dependable delivery schedules. Their ability to adapt to changing supply chain demands and regional requirements minimizes disruptions, allowing clients to maintain seamless operations.

Proactive Problem-Solving

What truly sets world-class customer support apart is its proactive nature. These manufacturers anticipate potential challenges, such as shifts in regulatory requirements or fluctuations in raw material availability, and provide solutions before issues arise. This forward-thinking approach not only reduces risks but also strengthens the customer’s confidence in their supplier.

The Competitive Edge

Exceptional customer support goes beyond meeting expectations—it drives customer success. By partnering with a manufacturer that prioritizes service, businesses gain a competitive edge through expert collaboration, operational efficiency, and peace of mind, ensuring a foundation for long-term growth.

What Industries Rely on High-Quality HPMC Manufacturers?

Construction

The construction industry relies heavily on HPMC for its ability to enhance the performance of dry-mix mortars, cement, and tile adhesives. HPMC improves water retention, ensuring proper curing of cement and mortar to achieve maximum strength and durability. It also enhances workability, making it easier for workers to apply smooth, uniform finishes. From residential projects to large-scale infrastructure developments, HPMC is essential for achieving long-lasting and reliable construction outcomes.

Pharmaceuticals

In the pharmaceutical sector, where precision and safety are non-negotiable, HPMC plays a critical role. It is commonly used as a binder in tablets, a protective coating agent to shield active ingredients, and a controlled-release matrix to ensure precise and sustained drug delivery. Pharmaceutical-grade HPMC adheres to strict purity standards, making it vital for the safety, efficacy, and consistency of medications, from over-the-counter remedies to advanced therapeutics.

Food and Cosmetics

HPMC serves as a versatile stabilizer, thickener, and emulsifier in the food and cosmetics industries. In food production, it helps maintain the texture and consistency of products such as sauces, dressings, and gluten-free baked goods. In cosmetics, HPMC enhances product stability while creating smooth, luxurious textures in formulations like creams, gels, and lotions.

Paints and Coatings

In paints and coatings, HPMC ensures uniform viscosity, improves adhesion, and prevents sagging during application. Its thickening and stabilizing properties contribute to a smoother application process and a high-quality finish, making it indispensable for both decorative and industrial coatings.

Personal Care Products

HPMC is widely used in personal care items such as shampoos, conditioners, and toothpaste. It provides the desired consistency, enhances foam stability, and ensures uniform distribution of active ingredients. Its safety and compatibility with various formulations make it a key ingredient in this industry.

Why High-Quality HPMC Manufacturers Matter

These industries depend on consistent, application-specific solutions that only high-quality HPMC manufacturers can provide. Their ability to deliver tailored products with reliable performance ensures that businesses can meet regulatory standards, maintain production efficiency, and satisfy customer expectations. This reliability shapes industry success, enabling innovation and long-term growth.

How Does Pricing Reflect Quality?

Pricing in HPMC manufacturing goes beyond mere cost—it reflects the value, reliability, and long-term benefits a manufacturer provides. While lower prices may seem appealing at first glance, they can sometimes indicate compromises in quality, such as inconsistent performance, inadequate quality control, or the use of substandard raw materials. On the other hand, high-quality manufacturers focus on delivering value through a balance of efficiency and excellence.

Cost-Effectiveness Without Compromise

Top manufacturers achieve competitive pricing without sacrificing quality by leveraging advanced production technologies, bulk procurement of raw materials, and optimized operational processes. This approach allows them to deliver high-quality HPMC efficiently while maintaining consistent performance and safety standards. Their pricing reflects their ability to offer cost-effective solutions that meet the needs of demanding industries.

Investment in Quality and Innovation

High-quality manufacturers often command slightly higher prices due to their investment in superior technology, rigorous testing protocols, and sustainable practices. These investments ensure that every batch of HPMC meets stringent industry requirements, whether for pharmaceutical purity, construction performance, or food safety. The result is a product that performs reliably and reduces downstream risks for their customers, such as production inefficiencies, product recalls, or regulatory violations.

The Hidden Costs of Low-Quality HPMC

Low-cost HPMC might save money upfront, but the hidden costs can be significant. Poor-quality materials can lead to production delays, product failures, and reputational damage, all of which can far outweigh any initial savings. For instance, inconsistent viscosity could disrupt a mortar mix, or impurities in pharmaceutical-grade HPMC could result in failed regulatory compliance.

Evaluating Pricing and Quality

To determine whether a manufacturer’s pricing reflects quality, businesses should consider:

- The manufacturer’s certifications, such as ISO 9001 or FDA approval.

- Their commitment to sustainable practices, indicating responsible and efficient operations.

- The track record of consistency in product performance and reliable delivery.

- The level of technical support and customization they provide.

The Value of Long-Term Partnerships

Paying slightly more for high-quality HPMC is an investment in reliability, safety, and customer satisfaction. Businesses benefit from reduced risks, enhanced product performance, and stronger market positioning, ensuring that the true value of the product extends far beyond its price tag.

What Are the Red Flags to Avoid in HPMC Manufacturers?

Choosing the wrong HPMC manufacturer can lead to significant setbacks in production, quality, and overall business operations. Identifying red flags early in the selection process is crucial to avoid costly mistakes. Here are the key warning signs to watch for:

Inconsistent Product Quality

Variability in product quality is a major red flag. Indicators include inconsistent viscosity, poor solubility, or elevated impurity levels. Such issues can disrupt production processes, compromise the performance of end products, and create reputational risks. For industries like construction, where water retention and workability are critical, or pharmaceuticals, where purity is paramount, these inconsistencies can be disastrous.

Lack of Certifications and Transparency

Reputable HPMC manufacturers readily provide proof of compliance with industry standards such as ISO 9001, ISO 14001, FDA approval, or REACH certification. A lack of transparency in certifications, testing data, or regulatory compliance documentation is a warning sign that the manufacturer may not meet global quality standards. Vague or evasive responses regarding quality control processes or product traceability should not be ignored.

Poor Customer Service

Customer support is a key indicator of a manufacturer’s reliability. Delayed responses to inquiries, lack of technical expertise, or an unwillingness to provide formulation guidance reflect poor customer service. A lack of proactive communication regarding potential challenges, such as raw material shortages or delivery timelines, signals a lack of commitment to meeting client needs.

Unreliable Delivery Schedules

Frequent delays in product delivery or failure to honor agreed schedules can disrupt your supply chain and lead to production downtime. Manufacturers who struggle to meet delivery timelines demonstrate a lack of operational efficiency or logistical planning, making them a risky choice for businesses that require consistency.

Limited Customization Options

An inability or unwillingness to customize HPMC formulations to meet specific application needs is another red flag. Industries such as pharmaceuticals, construction, and cosmetics often require tailored solutions for optimal performance. A lack of flexibility in product offerings indicates a manufacturer’s limitations in catering to diverse industry demands.

Mitigating Risks When Selecting a Manufacturer

To proactively avoid these red flags, businesses can:

- Request detailed certifications and testing reports to verify quality standards.

- Evaluate sample batches for consistency, viscosity, and other key performance metrics.

- Conduct site audits or virtual tours to assess manufacturing processes and compliance.

- Research customer reviews and testimonials to gauge the manufacturer’s reputation.

- Establish clear communication expectations and test the responsiveness of the customer support team.

By identifying and addressing potential risks upfront, businesses can ensure they partner with a reliable HPMC manufacturer capable of delivering consistent quality, dependable service, and tailored solutions.

What Questions Should Buyers Ask Before Choosing an HPMC Manufacturer?

Selecting the right HPMC manufacturer involves more than comparing prices—it requires thorough evaluation to ensure the manufacturer can meet your quality, reliability, and application-specific needs. Asking the right questions is key to identifying the best partner.

1. Can You Provide Product Samples for Testing?

Testing product samples is essential to assess consistency, viscosity, solubility, and overall performance in your specific applications. This step ensures that the HPMC meets your technical requirements before committing to large-scale procurement. A manufacturer that readily provides samples demonstrates transparency and confidence in their product quality.

2. Do You Offer Customization Options?

Industries often require tailored solutions. Ask whether the manufacturer can adjust substitution levels of methoxyl or hydroxypropyl groups, or modify viscosity and particle size, to suit your application. Customization capabilities highlight a manufacturer’s technical expertise and commitment to addressing unique needs across sectors like construction, pharmaceuticals, and cosmetics.

3. What Certifications Do You Hold?

Certifications are a reliable indicator of quality and compliance. Confirm whether the manufacturer holds certifications such as:

- ISO 9001 (Quality Management)

- ISO 14001 (Environmental Management)

- FDA approvals (for pharmaceutical or food-grade HPMC)

- REACH compliance (for chemical safety in international markets)

These certifications ensure that the HPMC adheres to industry regulations and global safety and environmental standards.

4. What Are Your Quality Control Processes?

Inquire about the manufacturer’s quality control measures, including testing protocols for viscosity, purity, and consistency. Understanding how they maintain product uniformity across batches ensures that you’re partnering with a manufacturer who prioritizes reliability.

5. What Is Your Delivery Track Record?

Timely delivery is critical to avoid production delays. Ask about their logistics capabilities, lead times, and ability to adapt to urgent or fluctuating demands. A dependable delivery system indicates operational efficiency and a commitment to meeting customer timelines.

6. Do You Provide Technical Support?

Strong technical support can make a significant difference in optimizing product performance. Ask whether the manufacturer offers guidance on formulation challenges, troubleshooting, or application-specific advice. A supportive partner can help streamline your production processes and maximize results.

7. What Sustainability Practices Do You Follow?

For businesses prioritizing eco-friendly practices, it’s important to ask about the manufacturer’s sustainability initiatives. Do they source renewable raw materials? Are their production processes energy-efficient and compliant with environmental standards such as ISO 14001? Sustainable practices benefit not only the environment but also your brand reputation.

8. What Is Your Experience in My Industry?

Understanding a manufacturer’s experience in your sector provides insight into their ability to meet your unique requirements. Ask for case studies or references from businesses in similar industries, such as construction, pharmaceuticals, or food.

Additional Factors for a Successful Partnership

- Transparency: Can the manufacturer provide detailed documentation on product specifications, testing, and compliance?

- Reputation: What do existing clients say about their products and services?

- Scalability: Can the manufacturer scale production to match your growing needs?

By addressing these questions, buyers can confidently identify an HPMC manufacturer that aligns with their operational demands, quality expectations, and long-term goals.

Case Studies: Success Stories from Top HPMC Manufacturers

Real-world examples illustrate how partnering with a high-quality HPMC manufacturer can address critical challenges, drive innovation, and deliver measurable results across industries.

Construction: Solving Mortar Inconsistencies

A construction company was facing frequent complaints about the uneven performance of their mortar products, stemming from low-quality HPMC with variable viscosity and poor water retention. After partnering with a leading HPMC manufacturer, they received a customized formulation designed to optimize water retention, extend open time, and improve workability. This resulted in smoother applications, reduced cracking, and significantly stronger structures.

Impact:

- Decrease in project delays due to improved mortar handling.

- Enhanced durability of finished structures, boosting client satisfaction.

- Increased market reputation, securing more high-value contracts.

Pharmaceuticals: Ensuring Tablet Precision and Safety

A pharmaceutical company needed an HPMC coating agent to produce controlled-release tablets with precise dissolution rates. Their previous supplier provided inconsistent quality, leading to failed batches and compliance concerns. By switching to a top-tier HPMC manufacturer with pharmaceutical-grade certifications, they gained access to high-purity, consistent HPMC optimized for controlled-release functionality. This partnership enabled the company to meet stringent regulatory standards and ensure product safety and efficacy.

Impact:

- Streamlined production processes with fewer failed batches.

- Improved product reputation in the market, leading to increased sales.

- Reduced production waste and associated costs, boosting profitability.

Food Industry: Enhancing Gluten-Free Products

A food manufacturer specializing in gluten-free baked goods struggled to achieve the desired texture and consistency in their products. Collaborating with a leading HPMC manufacturer, they received a tailored solution that improved dough elasticity, water absorption, and product stability. The result was a line of gluten-free bread and pastries that closely matched the texture of traditional products.

Impact:

- Increased customer satisfaction due to improved product quality.

- Expanded market reach by catering to gluten-sensitive consumers.

- Higher production efficiency, reducing costs and improving margins.

Actionable Insights for Businesses

1.Customization Delivers Results: Partnering with a manufacturer capable of tailoring HPMC formulations ensures products meet specific industry demands, improving functionality and customer satisfaction.

2.Consistency Is Key: Reliable, high-quality HPMC minimizes production inefficiencies, reduces waste, and ensures regulatory compliance.

3.Collaboration Matters: Open communication and technical support from the manufacturer enable businesses to optimize formulations and address challenges proactively.

4.Long-Term Impact: Investing in a high-quality manufacturer may have higher upfront costs but delivers lasting benefits in terms of performance, reputation, and profitability.

These success stories underscore the value of selecting a trusted HPMC partner, transforming challenges into opportunities for growth and innovation.

Conclusion

Choosing the right HPMC manufacturer isn’t just a transaction—it’s a strategic move that can shape the efficiency, reliability, and growth of your business. High-quality manufacturers stand out with advanced production technologies, a commitment to consistent quality, robust certifications, and the flexibility to provide tailored solutions. These strengths translate into superior product performance, supply chain reliability, and long-term customer satisfaction.

Taking the time to carefully evaluate potential suppliers is essential. Ask the critical questions, review certifications, test product samples, and consider their track record in your industry. A trusted manufacturing partner can become a cornerstone of your success, offering not just quality products but also expert guidance and dependable support.

Ready to take the next step? Use the strategies and insights shared here to identify an HPMC manufacturer that aligns with your goals and sets your business on a course for sustained excellence.

FAQ: Common Questions About Choosing a High-Quality HPMC Manufacturer

1.What certifications should I look for in an HPMC manufacturer?

Look for manufacturers with ISO 9001 for quality management and ISO 14001 for environmental sustainability. For food and pharmaceutical applications, ensure compliance with FDA regulations, EU standards, and REACH certification for chemical safety.

2.How can I test the quality of HPMC before making a bulk purchase?

Reliable manufacturers provide product samples for testing. Evaluate critical parameters such as viscosity, solubility, particle size, and purity to confirm the product aligns with your application requirements.

3.Can HPMC manufacturers customize formulations to meet my specific needs?

Yes, leading manufacturers offer customized formulations, adjusting substitution levels of methoxyl and hydroxypropyl groups to achieve specific viscosity, water retention, or film-forming properties tailored to your industry needs.

4.What are the risks of choosing a low-quality HPMC manufacturer?

Working with a low-quality manufacturer can result in inconsistent products, high impurity levels, or poor solubility, leading to production inefficiencies, product failures, or even regulatory compliance issues in sensitive industries.

5.How do I ensure the manufacturer’s consistency and reliability?

Select manufacturers with rigorous quality control protocols, advanced testing equipment, and a proven track record of on-time deliveries. Verify their adherence to certifications like ISO standards as an assurance of reliability.

6.What industries rely heavily on high-quality HPMC?

Industries such as construction (tile adhesives, cement), pharmaceuticals (controlled-release drugs, coatings), food (stabilizers, thickeners), and cosmetics (texture enhancers, stabilizers) depend on high-quality HPMC for optimal product performance.

7.Does sustainable manufacturing matter in HPMC production?

Yes, sustainability is increasingly important. Look for manufacturers employing eco-friendly practices, waste recycling, and carbon reduction initiatives. This not only supports ethical production but also aligns with environmentally responsible supply chains.

8.What should I ask when negotiating with an HPMC manufacturer?

Ask about their customization capabilities, certifications, delivery reliability, and whether they provide technical support for your specific applications. These inquiries will help you evaluate their ability to meet your business needs.

By starting with these questions, you’ll be well-prepared to identify an HPMC manufacturer that can deliver consistent quality, technical expertise, and reliable service for your business.