Finding the right HPMC manufacturer for your business needs can be challenging in today’s competitive market. Many purchasing managers struggle to identify reliable suppliers that offer consistent quality, competitive pricing, and dependable service. This article provides a comprehensive analysis of the leading HPMC manufacturers globally, helping you make informed decisions for your pharmaceutical, construction, or food industry applications. With over 20 years of industry experience evaluating hydroxypropyl methylcellulose suppliers, we’ve compiled the essential information you need.

1. What Is HPMC and Why Is It Important for Various Industries?

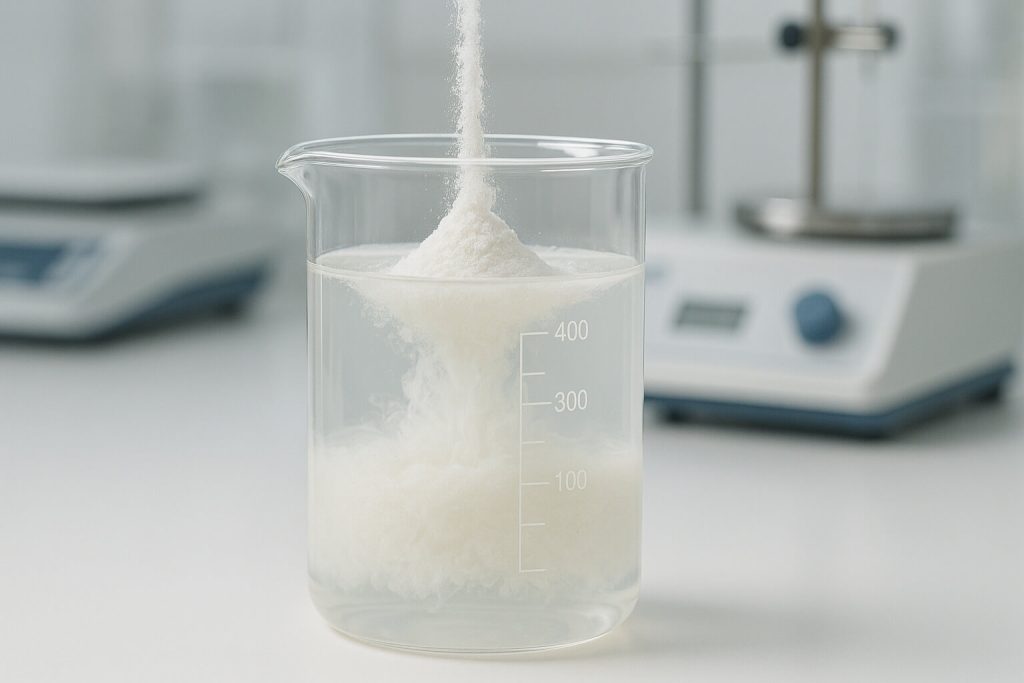

Hydroxypropyl Methylcellulose (HPMC) is a semi-synthetic, inert polymer derived from cellulose. It functions as a versatile additive with unique properties including water solubility, film-forming capabilities, and viscosity control. But here’s the thing – not all HPMC products are created equal, and understanding the fundamentals is crucial for making informed purchasing decisions.

HPMC consists of cellulose ethers modified with hydroxypropyl and methyl groups, giving it specific performance characteristics that vary based on substitution levels. The material appears as a white to off-white powder that dissolves in cold water to form clear solutions of varying viscosities.

| Industry | Primary HPMC Applications | Key Benefits |

|---|---|---|

| Pharmaceutical | Tablet coatings, Matrix systems | Controlled release, Film formation |

| Construction | Mortars, Renders, Tile adhesives | Water retention, Workability |

| Food | Bakery products, Sauces | Thickening, Stabilization |

| Personal Care | Shampoos, Creams | Viscosity control, Film formation |

| Paints & Coatings | Water-based paints | Thickening, Anti-settling |

The global HPMC market continues to grow steadily, with projections indicating a compound annual growth rate of approximately 6.2% through 2028. This growth is driven by increasing demand across all major application sectors, particularly in emerging economies.

You might be wondering why selecting the right HPMC manufacturer matters so much. The answer lies in the critical nature of this ingredient – variations in quality can significantly impact product performance, regulatory compliance, and ultimately, your business reputation.

2. How Do the Leading HPMC Manufacturers Compare in Global Market Share?

When evaluating HPMC suppliers, understanding their market position provides valuable context for decision-making. The truth is market share often correlates with production capacity, quality consistency, and overall reliability – factors that directly impact your supply chain.

The global HPMC market features several dominant players alongside smaller, specialized manufacturers. Chinese manufacturers have significantly increased their market presence over the past decade, challenging the traditional dominance of Western and Japanese companies.

| Manufacturer | Approximate Market Share | Regional Strength | Production Capacity (MT/year) | Key Quality Certifications |

|---|---|---|---|---|

| Shin-Etsu Chemical | 18-20% | Global, strong in Asia | 30,000+ | ISO 9001, ISO 14001, GMP |

| Dow Chemical | 15-17% | Americas, Europe | 25,000+ | ISO 9001, ISO 14001, GMP |

| Ashland Inc. | 12-14% | Americas, Europe | 20,000+ | ISO 9001, ISO 14001, GMP |

| SE Tylose | 8-10% | Europe | 15,000+ | ISO 9001, ISO 14001, GMP |

| Shandong Head | 7-9% | Asia, expanding globally | 20,000+ | ISO 9001, ISO 14001 |

| Anhui Shanhe | 5-7% | Asia | 15,000+ | ISO 9001, ISO 14001 |

| Henan Tiansheng | 4-6% | Asia | 10,000+ | ISO 9001, ISO 14001 |

| Lotte Chemical | 3-5% | Asia | 8,000+ | ISO 9001, ISO 14001, GMP |

| Hercules-Luzhou | 3-4% | Asia, Americas | 7,000+ | ISO 9001, ISO 14001 |

| Celotech | 2-3% | Asia | 5,000+ | ISO 9001, ISO 14001 |

Quality certification standards vary among manufacturers, with most top-tier suppliers maintaining ISO 9001 quality management systems. Pharmaceutical-grade HPMC producers typically hold additional certifications such as GMP, while food-grade suppliers often maintain FSSC 22000 food safety certification.

Here’s something important to consider – while market share provides useful context, your specific application requirements should ultimately guide manufacturer selection. A smaller manufacturer with specialized expertise in your particular application might offer better value than a market leader with a broader focus.

3. What Quality Parameters Should You Evaluate When Selecting HPMC Suppliers?

Selecting the right HPMC supplier requires thorough evaluation of multiple quality parameters. The reality is that even minor variations in HPMC properties can significantly impact your product performance, making quality assessment a critical step in supplier selection.

Industry-specific quality standards vary considerably. Pharmaceutical applications demand compliance with pharmacopeia standards (USP, EP, JP), while construction applications focus on performance parameters like water retention and workability.

| Quality Parameter | Measurement Method | Typical Range | Impact on Performance |

|---|---|---|---|

| Viscosity | Rotational viscometer | 3 – 100,000 mPa·s | Flow behavior, film thickness |

| Methoxyl Content | Gas chromatography | 19-30% | Solubility, thermal gelation |

| Hydroxypropoxyl Content | Gas chromatography | 4-12% | Surface activity, solubility |

| Particle Size | Laser diffraction | 95% < 100 μm | Dissolution rate |

| Moisture Content | Loss on drying | ≤ 5% | Storage stability |

Purity levels and testing methodologies should align with your specific application requirements. Pharmaceutical grades undergo more rigorous testing for residual solvents, heavy metals, and microbiological contaminants compared to construction grades.

Batch consistency represents another crucial quality factor. Reputable manufacturers maintain tight control over production parameters and conduct comprehensive batch testing to ensure consistent performance.

You need to know that establishing a supplier qualification program with defined acceptance criteria for each quality parameter provides the most reliable approach to HPMC supplier selection. This structured approach ensures objective evaluation and minimizes the risk of quality-related issues.

4. Which HPMC Manufacturers Offer the Best Value for Pharmaceutical Applications?

Pharmaceutical applications demand HPMC with exceptional purity, consistency, and regulatory compliance. Let me be clear – when it comes to pharmaceutical ingredients, value encompasses more than just price; it includes quality assurance, regulatory support, and technical expertise.

| Manufacturer | Pharmaceutical Grade Offerings | Regulatory Documentation | Technical Support Level | Relative Cost Position |

|---|---|---|---|---|

| Shin-Etsu Chemical | Extensive range (METOLOSE®) | DMFs, CEPs, comprehensive | Excellent, global | Premium |

| Dow Chemical | Comprehensive (METHOCEL™) | DMFs, CEPs, comprehensive | Excellent, global | Premium |

| Ashland Inc. | Broad range (BENECEL™) | DMFs, CEPs, comprehensive | Very good, global | High |

| Shandong Head | Growing portfolio | DMFs, basic documentation | Good, improving | Competitive |

| Lotte Chemical | Selected grades | DMFs, moderate documentation | Good, regional | Moderate |

A cost-effectiveness analysis reveals significant price variations among suppliers, with Western and Japanese manufacturers typically commanding premium prices justified by their extensive regulatory support, technical expertise, and quality consistency. Chinese manufacturers generally offer more competitive pricing but may provide less comprehensive regulatory documentation.

Several case studies demonstrate successful pharmaceutical applications. For controlled-release matrix tablets, Shin-Etsu’s METOLOSE® 90SH and Dow’s METHOCEL™ K15M have established strong reputations for consistent performance. Film coating applications frequently utilize Ashland’s BENECEL™ E15 and Dow’s METHOCEL™ E5 with documented success.

Here’s what matters most – pharmaceutical manufacturers should prioritize suppliers with strong regulatory documentation, consistent quality, and technical support capabilities, even if this means paying premium prices. The cost of regulatory issues or formulation failures far outweighs potential savings from lower-priced HPMC with less robust quality systems.

5. How Do Construction Industry HPMC Products Differ Among Top Manufacturers?

Construction applications utilize HPMC primarily for its water retention, workability improvement, and adhesion enhancement properties. The bottom line is that construction-grade HPMC products show significant performance variations among manufacturers, directly impacting application properties and jobsite efficiency.

| Manufacturer | Construction Grade Series | Water Retention | Workability Improvement | Setting Time Impact | Regional Availability |

|---|---|---|---|---|---|

| Ashland Inc. | CULMINAL™ | Excellent (>98%) | Very good | Moderate delay | Global, strong in Americas |

| SE Tylose | TYLOSE® MH | Excellent (>98%) | Excellent | Minimal delay | Europe, Middle East |

| Dow Chemical | WALOCEL™ | Very good (>95%) | Good | Moderate delay | Global |

| Shandong Head | MHPC | Good (>90%) | Good | Moderate delay | Asia, expanding globally |

| Henan Tiansheng | HPMC-C | Good (>90%) | Moderate | Significant delay | Asia, limited elsewhere |

Setting time and strength development comparisons reveal important differences among suppliers. Some HPMC products cause minimal retardation of cement hydration, while others significantly delay setting. This property must be carefully matched to application requirements – tile adhesives may benefit from extended open time, while renders may require faster setting.

Cost-benefit analysis for construction applications must consider not only the HPMC price but also its dosage efficiency. Premium products often require lower dosages to achieve target properties, potentially offsetting their higher unit cost.

You should consider this – while construction applications may seem less demanding than pharmaceutical uses, the performance impact of HPMC quality can be substantial. Selecting the right supplier requires balancing immediate cost considerations against performance reliability and technical support needs.

6. What Supply Chain Factors Should Influence Your HPMC Manufacturer Selection?

Supply chain considerations play a crucial role in HPMC manufacturer selection, particularly in today’s volatile global market. I need to emphasize that even the highest quality product provides little value if it cannot be reliably delivered when and where you need it.

| Manufacturer | Production Locations | Inventory Hubs | Typical Lead Times | Supply Chain Resilience Rating |

|---|---|---|---|---|

| Shin-Etsu Chemical | Japan, Germany, US | Global network | 4-6 weeks | Excellent |

| Dow Chemical | US, Germany, China | Global network | 4-6 weeks | Excellent |

| Ashland Inc. | US, Mexico, China | Global network | 4-8 weeks | Very good |

| SE Tylose | Germany | Europe, Asia | 6-8 weeks | Good |

| Shandong Head | China | China, limited global | 6-10 weeks | Moderate |

Supply reliability and contingency planning deserve careful consideration. Top-tier manufacturers maintain buffer inventory at strategic locations and have established business continuity plans for various disruption scenarios. During supplier evaluation, request information about their approach to supply chain risk management.

Lead times and inventory management practices vary significantly among suppliers. Western and Japanese manufacturers typically offer more predictable lead times but may require longer planning horizons. Chinese manufacturers sometimes provide shorter quoted lead times but may experience greater variability in actual delivery performance.

What you really need to understand is that supply chain resilience has become increasingly important in recent years. The COVID-19 pandemic, shipping container shortages, and regional conflicts have all highlighted the value of working with manufacturers that maintain robust supply networks and contingency plans.

7. How Can You Establish Effective Long-term Partnerships with HPMC Suppliers?

Building strategic relationships with HPMC suppliers can provide significant advantages beyond transactional purchasing. The honest truth is that well-structured supplier partnerships deliver value through preferential treatment during shortages, collaborative problem-solving, and often more favorable commercial terms.

| Partnership Element | Key Considerations | Best Practices |

|---|---|---|

| Contract Structure | Term length, volume commitments | 2-3 year agreements with annual volume targets |

| Quality Agreements | Specifications, testing, change control | Comprehensive agreement with clear responsibilities |

| Performance Metrics | KPIs for quality, delivery, service | Quarterly scorecard reviews with improvement targets |

| Communication Channels | Regular meetings, technical exchanges | Structured communication plan with defined frequency |

| Collaborative Development | Joint projects, exclusivity considerations | Formal project structure with clear objectives |

Collaborative product development opportunities represent a significant benefit of strategic supplier relationships. Leading HPMC manufacturers often work with key customers to develop customized grades for specific applications or to solve particular formulation challenges.

Cost management and price stability arrangements help mitigate the impact of raw material fluctuations and market volatility. Consider mechanisms such as price bands with defined adjustment triggers, raw material indexing for portion of price, and volume-based incentive structures.

You’ll find that investing time in relationship development with strategic HPMC suppliers yields significant returns through preferential treatment, collaborative problem-solving, and often more favorable commercial terms during industry-wide challenges.

Conclusion

Selecting the right HPMC manufacturer for your business requires careful evaluation of multiple factors beyond simple price comparison. Throughout this article, we’ve examined the key considerations that should guide your decision-making process, from quality parameters and application-specific requirements to supply chain resilience and partnership opportunities.

The top 10 HPMC manufacturers each offer distinct advantages in terms of product quality, regulatory support, technical expertise, and regional presence. Your optimal choice depends on your specific industry requirements, quality expectations, and supply chain priorities. By applying the evaluation framework outlined in this article, you can identify the supplier that best aligns with your business needs.

We encourage you to contact us for personalized consultation on HPMC supplier selection. Our technical experts can help you navigate the complexities of supplier qualification and develop a strategic sourcing approach that enhances your product performance while optimizing total cost of ownership. Your success with HPMC applications begins with making the right supplier choice today.

FAQ Section

Q1: What is the difference between pharmaceutical and food-grade HPMC?

Pharmaceutical-grade HPMC meets stricter purity requirements with lower limits for heavy metals, residual solvents, and microbiological contaminants. It must comply with pharmacopeia standards (USP, EP, JP) and typically comes with more extensive documentation including Drug Master Files. Food-grade HPMC (E464) focuses on food safety regulations with specifications for pesticide residues, heavy metals, and microbiological quality appropriate for food contact. Documentation for food-grade focuses on food safety certifications like FSSC 22000 rather than pharmaceutical regulatory filings.

Q2: How does HPMC viscosity affect its performance in different applications?

HPMC viscosity, measured in mPa·s, directly impacts performance across applications. In pharmaceuticals, low-viscosity grades (3-15 mPa·s) create thin, uniform film coatings, while medium-viscosity grades (100-4,000 mPa·s) provide controlled drug release in matrix tablets. In construction, higher viscosities (15,000-100,000 mPa·s) improve water retention in mortars and prevent sagging in renders. Food applications use low to medium viscosities for thickening and stabilization, with the specific grade selected based on desired texture and processing conditions.

Q3: Which HPMC manufacturers offer the most competitive pricing for bulk orders?

Chinese manufacturers generally offer the most competitive pricing for bulk HPMC orders, with companies like Shandong Head, Anhui Shanhe, and Henan Tiansheng typically providing rates 15-30% below Western and Japanese competitors. However, pricing competitiveness must be evaluated alongside quality consistency, regulatory documentation, and technical support capabilities. Volume discounts vary significantly among suppliers, with some offering tiered pricing starting at 1 metric ton and others requiring 5+ metric tons for meaningful discounts.

Q4: What are the most important certifications to look for when selecting an HPMC supplier?

The most important certifications vary by application. For pharmaceutical applications, prioritize manufacturers with ISO 9001 quality management certification, GMP compliance, and regulatory filings like FDA Drug Master Files and EDQM Certificates of Suitability. For food applications, look for FSSC 22000 or BRC food safety certifications, kosher and halal certifications if relevant to your market. Construction applications should focus on ISO 9001 certification and product-specific performance certifications like CE marking for European markets.

Q5: How stable is the global supply chain for HPMC raw materials?

The global supply chain for HPMC raw materials faces moderate volatility due to several factors. The primary raw materials—wood pulp, propylene oxide, and methyl chloride—are subject to price fluctuations based on energy costs, transportation disruptions, and regional capacity constraints. Recent years have seen increased supply chain challenges due to global shipping disruptions, container shortages, and regional manufacturing restrictions. To mitigate these risks, leading HPMC manufacturers maintain diversified raw material sourcing strategies, buffer inventory policies, and production flexibility across multiple sites.