Understanding how hypromellose (HPMC) can enhance matrix tablets for controlled release is key for pharmaceutical manufacturers and decision-makers in the industry. HPMC is a vital excipient, largely due to its unique properties that facilitate the extended release of active ingredients, improve stability, and enhance patient compliance. In this article, we will delve into the effectiveness of hypromellose in matrix tablets, examining its benefits, formulation considerations, challenges, evaluation methods, applications, and future developments.

How Does Hypromellose Work in Matrix Tablets?

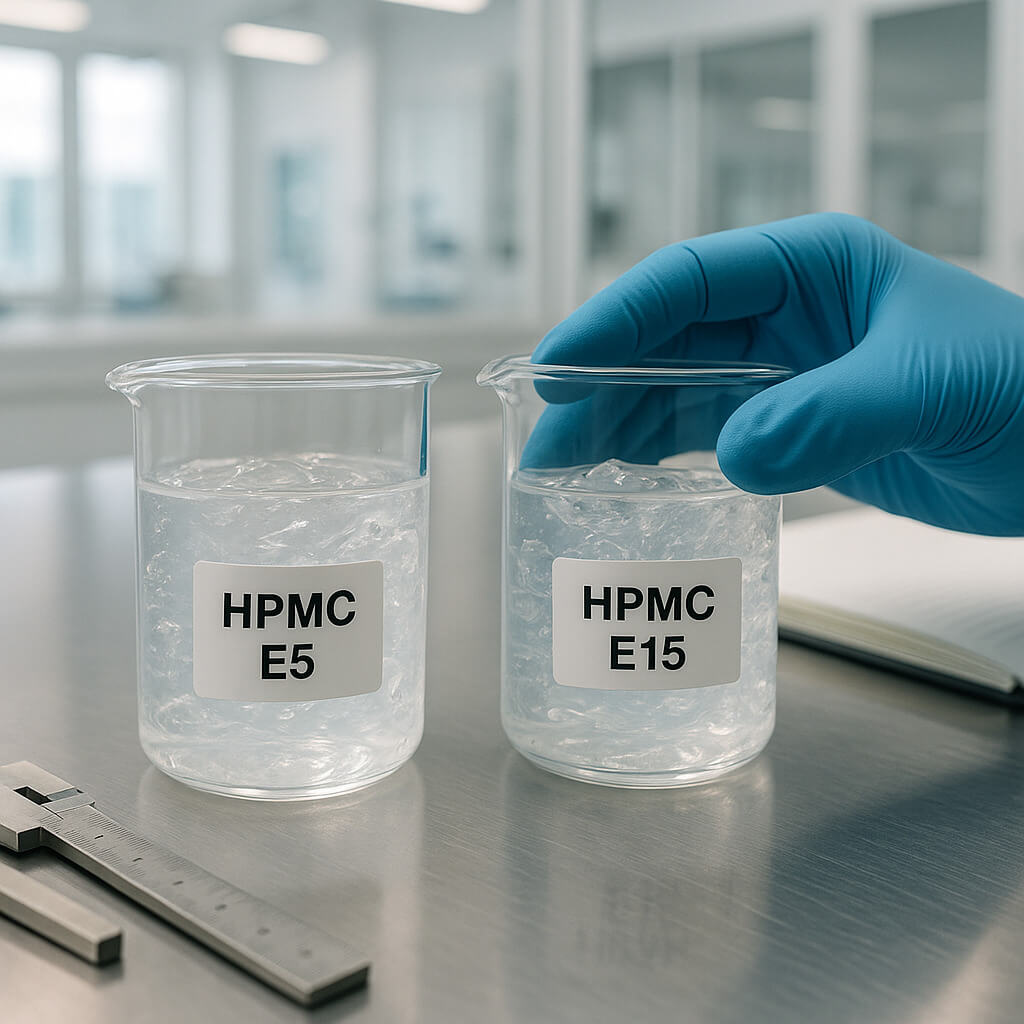

Hypromellose operates as a binder and thickening agent in pharmaceutical formulations, and it’s especially effective in controlled release applications. This polymer’s ability to form a gel when hydrated plays a significant role in modulating the drug release rate from matrix tablets. As water penetrates the tablet matrix, hypromellose hydrates and swells, gradually releasing the active ingredient embedded within.

But here’s the kicker: the viscosity and molecular weight of hypromellose can be adjusted to suit specific formulation needs. Lower molecular weight grades provide faster drug release, while higher molecular weight grades promote slower release rates, giving formulators flexibility in designing the drug delivery system. The solubility and gel-forming characteristics help create an environment where the drug can be released in a controlled manner over time.

In addition to its gel-forming ability, hypromellose is also non-toxic and widely recognized for its compatibility with various pharmaceuticals, making it an ideal choice for both solid and liquid formulations. Studies have shown that hypromellose can enhance drug absorption and bioavailability, which is particularly crucial for poorly soluble compounds. This versatility has led to significant adoption across various therapeutic fields, making it a staple in the pharmaceutical industry.

| Propiedad | Bajo peso molecular | Alto peso molecular |

|---|---|---|

| Drug Release Rate | Más rápido | Más lento |

| Viscosidad | Más bajo | Más alto |

| Uso recomendado | Rapid-release formulas | Sustained-release designs |

What Are the Advantages of Using Hypromellose in Tablets?

Utilizing hypromellose in matrix tablets offers numerous advantages that directly contribute to patient compliance and overall drug efficacy. Primarily, one of the most significant benefits is the enhancement of controlled release technology. This translates to medications that do not need to be administered as frequently, thereby improving adherence to treatment regimens.

What’s the real story? Research has shown that formulations using hypromellose can lead to a more consistent and predictable release of medication, which is essential in managing chronic conditions. For instance, in pain management therapies, maintaining stable blood levels of analgesics can be crucial for effectively managing pain without the peaks and troughs associated with immediate-release formulations.

Another compelling advantage is the increase in bioavailability for many active ingredients. Hypromellose can mitigate issues related to solubility, ensuring that drugs reach systemic circulation more efficiently. It has become especially essential for compounds that traditionally struggle to be properly absorbed in the gastrointestinal tract.

Moreover, hypromellose formulations are less susceptible to environmental factors like humidity compared to traditional types of excipients. This stability translates to an extended shelf life for the products, important for manufacturers looking to maximize the value of their products in the market. The versatility and efficient performance of hypromellose make it a smart option for pharmaceutical companies looking to enhance product offerings and meet stringent patient needs.

| Ventaja | Descripción |

|---|---|

| Liberación controlada | Enhances patient compliance through reduced dosing frequency |

| Improved Bioavailability | Provides better absorption for poorly soluble drugs |

| Mayor estabilidad | Offers longer shelf life and resistance to environmental factors |

What Are the Key Formulation Considerations?

When formulating matrix tablets with hypromellose, specific factors must be considered to optimize performance. First and foremost is selecting the right concentration of hypromellose. This choice directly impacts the tablet’s release profile; too little hypromellose may result in rapid release, while too much may slow it excessively.

Ready for the good part? Compatibility with other excipients is equally crucial. For instance, certain fillers or active pharmaceutical ingredients might interact adversely with hypromellose, affecting the tablet’s overall stability and performance. Therefore, comprehensive compatibility studies should always precede formulation attempts.

Another key consideration involves assessing the conditions of storage and processing. The temperature, humidity, and even the mixing techniques can influence the viscosity and gel-forming characteristics of hypromellose. Careful monitoring during the manufacturing process ensures that the final product meets specified quality attributes.

Additionally, the type of release mechanism desired needs to be defined early in the formulation process. Some formulations require immediate release, while others are better suited for sustained or controlled release profiles. Identifying the target release mechanism helps direct the concentration of hypromellose and other excipients included in the formulation, adopting an approach tailored to the desired therapeutic outcomes. These formulation considerations contribute greatly to the potential success of hypromellose matrix tablets in achieving their therapeutic goals.

| Consideración | Importancia |

|---|---|

| Hypromellose Concentration | Affects the release profile and efficacy |

| Excipients Compatibility | Ensures stability and effectiveness of the formulation |

| Storage and Processing Conditions | Influences viscosity and performance |

How Do Different Matrix Structures Impact Drug Release?

The structure of a matrix tablet significantly influences drug release profiles, and choosing the appropriate structure is imperative for achieving targeted release rates. Different types of matrix systems can be utilized, including hydrophilic, hydrophobic, and lag time systems. Each serves a unique purpose based on the desired therapeutic performance.

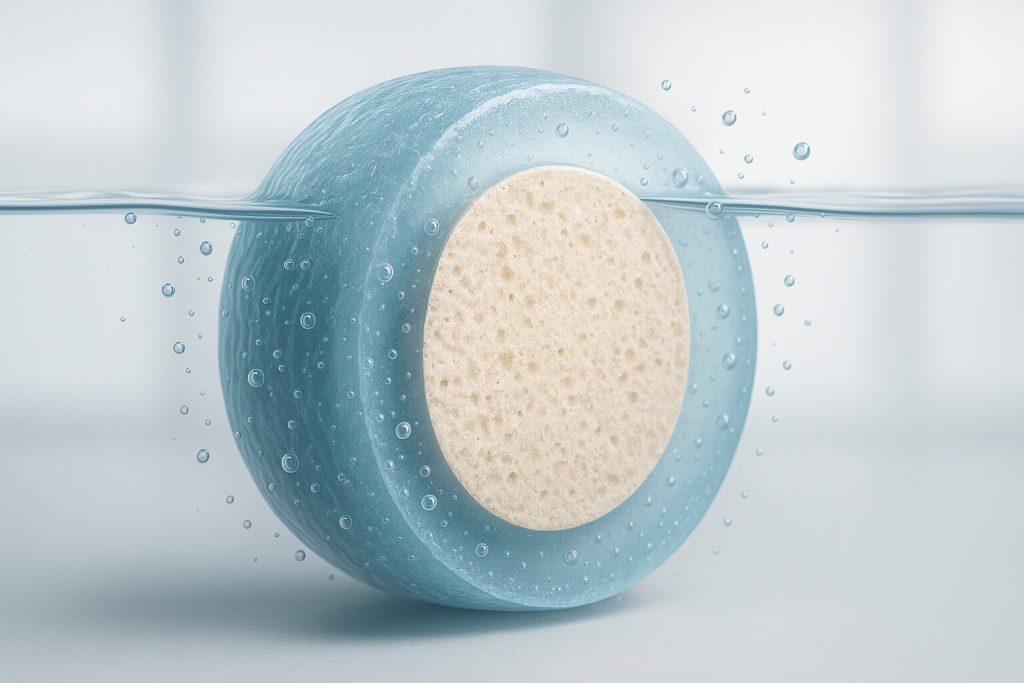

This is where it gets interesting: hydrophilic matrices rely on water absorption to facilitate drug release. When hydrated, these matrices swell and create a gel layer that controls the permeation of the dissolved drug into the gastrointestinal fluids. This method is particularly effective for drugs requiring a steady release.

On the other hand, hydrophobic matrices are composed of waxy materials that resist water penetration. Here, the release is regulated by diffusion through the polymer matrix. Hydrophobic matrices can provide prolonged release, often necessary for drugs that need a sustained effect.

Lag time systems offer a third option, where an initial period of no drug release occurs before the drug is released at a controlled rate. This mechanism is beneficial for drugs requiring a delay in onset, providing a burst of therapeutic activity only when necessary.

In summary, the choice of matrix structure directly impacts the drug release mechanism, which can be tailored to meet clinical objectives. By understanding how various structures facilitate drug delivery, formulators can design effective therapeutic strategies that enhance patient outcomes and productivity.

| Matrix Structure | Mecanismo | Drug Release Characteristics |

|---|---|---|

| Hydrophilic | Swelling and gel formation | Controlled, steady release over time |

| Hydrophobic | Diffusion through matrix | Slow, prolonged release |

| Lag time | Initial delay then control | Delayed onset followed by sustained release |

What Challenges Might You Encounter When Using Hypromellose?

Despite its numerous advantages, the use of hypromellose is not without its challenges. First is the potential for formulation instability. As hypromellose is sensitive to environmental conditions, variations in humidity or temperature can affect its performance, especially in storage and transportation.

One prevalent concern is the variability in drug release rates due to inconsistencies in how hypromellose hydrates in different formulations. It is crucial to conduct various stability studies and real-time assessments to ensure consistent product quality over time, addressing potential impacts on the release profile.

Another challenge may arise from the compatibility of hypromellose with certain active ingredients or other excipients. While it generally demonstrates excellent compatibility, some drugs may react unfavorably, leading to reduced efficacy or, in some cases, degradation of the active ingredient. A thorough understanding of ingredient interactions, alongside pre-formulation studies, can help mitigate these risks.

Lastly, maintaining the precise manufacturing conditions required for hypromellose formulations can present operational hurdles. Factors such as milling, mixing speeds, and temperature controls during tablet press operations can influence the final product characteristics. Companies may need to invest in quality control measures and specialized training for staff to adequately manage these variables.

These challenges are critical for ensuring successful integration of hypromellose in tableting applications, emphasizing the importance of careful monitoring and strategic planning.

| Desafío | Descripción |

|---|---|

| Formulation Instability | Variability in environmental conditions |

| Ingredient Compatibility | Potential adverse reactions with active ingredients |

| Manufacturing Process Control | Precision in operational conditions is crucial |

How Do You Evaluate the Effectiveness of Matrix Tablets?

Evaluating the effectiveness of matrix tablets containing hypromellose involves various methodologies designed to assess drug release profiles and overall product quality. First, in vitro dissolution testing is commonly employed. These tests simulate gastrointestinal conditions to measure the rate at which the drug is released from the tablet.

So what should you look for? The key parameters to measure include the time it takes for the drug to reach a specified concentration and the total amount released over a given timeframe. Critical to this process is ensuring that the dissolution testing aligns with regulatory standards, allowing for accurate comparisons with established benchmarks.

Additionally, stability testing is crucial. This involves storing the tablets under predetermined conditions (temperature, humidity) to observe any changes over time, which could affect drug release and overall shelf life. Real-time and accelerated stability studies provide valuable data on how long the formulation can maintain its integrity while delivering planned dosage performance.

Another vital aspect involves performing quality control checks throughout the manufacturing process. This includes ensuring that each batch meets established specifications concerning weight, thickness, and hardness, which can all impact the drug’s release profile and efficacy.

By applying these evaluation techniques, manufacturers can ensure that their hypromellose matrix tablets perform effectively, maintaining safety and delivering the intended therapeutic outcomes.

| Método de evaluación | Objetivo |

|---|---|

| In Vitro Dissolution Testing | Measures drug release rates under simulated conditions |

| Stability Testing | Assesses product integrity over time |

| Quality Control Checks | Ensures consistency in tablet characteristics |

What Real-World Applications Exist for Hypromellose Matrix Tablets?

Hypromellose matrix tablets have various applications across numerous therapeutic areas, demonstrating their versatility and effectiveness. One significant use is in pain management. For medications that require consistent plasma levels for effective pain relief, hypromellose matrices offer the sustained release necessary to prevent fluctuations in drug levels.

But here’s a noteworthy example: in the treatment of chronic conditions, such as diabetes or hypertension, patients benefit greatly from meeting their medication requirements without frequent dosing. Formulations that incorporate hypromellose ensure medical adherence and stabilize therapeutic levels without the need for multiple doses throughout the day.

Additionally, hypromellose is widely applied in formulations aimed at gastrointestinal disorders. The controlled release characteristic allows for targeted action over prolonged periods, which is particularly beneficial in managing symptoms such as reflux or colitis. Products designed for such applications show improved patient satisfaction, as they reduce the frequency of administration while maintaining effective symptom management.

In recent years, hypromellose has also found applications in oncology. Sustained release formulations can allow for the management of drug therapies that need to maintain effective dosing regimens over longer periods without the side effects often associated with conventional, immediate-release formulations.

The effectiveness of hypromellose in various therapeutic realms highlights its importance in modern pharmaceutical development and the enduring need for innovative solutions that prioritize patient well-being while maximizing the therapeutic benefits of medications.

| Área de aplicación | Impacto |

|---|---|

| Pain Management | Provides consistent plasma drug levels |

| Gastrointestinal Disorders | Improves patient adherence to treatment |

| Oncology | Facilitates sustained release of therapies |

What Future Developments Could Impact Hypromellose Use?

The future of hypromellose in matrix tablets appears promising, with ongoing research yielding exciting developments. First, advancements in material sciences continue to influence hypromellose formulations. Researchers are exploring new grades of hypromellose with tailored molecular weights that can impact drug release characteristics more precisely.

This is where it gets interesting: alternative delivery systems are also gaining traction. Innovations in drug delivery, such as nanoparticle technology and 3D printing, may soon allow for even more sophisticated uses of hypromellose. These technologies have great potential to integrate hypromellose into complex matrices designed for personalized medication needs.

Moreover, increasing regulatory scrutiny necessitates that manufacturers continually enhance their quality control and testing processes. This focus on rigorous development aligns with global movements toward personalized medicine and customized dosage forms, ensuring that pharmaceuticals meet specific patient requirements without compromising safety and effectiveness.

Finally, the rise of digital health technologies could streamline data collection for stability and effectiveness assessments, further refining formulations that use hypromellose. As the industry evolves, the integration of advanced analytics into formulation strategies could significantly enhance product development timelines and quality assurance.

As the pharmaceutical landscape changes, hypromellose will likely adapt and thrive, helping to usher in novel approaches to drug delivery that better meet the needs of practitioners and patients alike.

| Future Development | Implication |

|---|---|

| Advancements in Material Sciences | Tailored hypo grades for precise release profiles |

| Alternative Delivery Systems | Integration with novel technologies for personalized medicine |

| Enhanced Quality Control | Greater efficiency in developing safe, effective formulations |

Sección de preguntas frecuentes

Pregunta 1: What is Hypromellose?

Hypromellose, also known as HPMC, is a cellulose derivative commonly used as an excipient in pharmaceuticals for its thickening, binding, and film-forming properties.

Pregunta 2: How does Hypromellose work in controlled release tablets?

Hypromellose forms a gel in the presence of water, which controls the rate of drug release in the body by managing hydration and swelling characteristics.

Pregunta 3: What are the benefits of using Hypromellose in matrix tablets?

Using Hypromellose can enhance the bioavailability of drugs, improve patient compliance by extending the release period, and stabilize active pharmaceutical ingredients.

Pregunta 4: What formulation challenges can arise with Hypromellose?

Challenges include potential instability issues, incompatibility with certain active ingredients, and variations in release profiles due to inconsistent gel formation.

Pregunta 5: How can the effectiveness of Hypromellose matrix tablets be tested?

Effectiveness can be evaluated through in vitro drug release studies, ensuring that the tablets meet specified pharmacokinetic criteria during quality control.