Understanding the HPMC solubility chart is essential for industries that rely on Hydroxypropyl Methylcellulose (HPMC) as a key ingredient in formulations. HPMC is prominent in sectors like pharmaceuticals, food, and cosmetics due to its thickening, binding, and emulsifying properties. The significance of the solubility chart lies in its ability to outline how different grades of HPMC dissolve in various solvents under distinct conditions. This article aims to demystify the HPMC solubility chart, its relevance across multiple industries, and how to utilize it effectively. By the end, you’ll grasp not only what the chart is but also how to leverage its insights to optimize formulations and enhance product quality.

1. What Is HPMC and Why Is It Important?

Hydroxypropyl Methylcellulose, or HPMC, is a cellulose-derived polymer that has carved out a vital role in numerous applications. But here’s the kicker: despite being synthetically modified, it possesses characteristics similar to natural thickeners, making it safe and effective for diverse uses. HPMC is commonly employed in pharmaceutical formulations, food products, and personal care items, making its importance hard to overstate.

The history of HPMC dates back to the early 20th century, where it was first synthesized as a means to enhance the properties of cellulose. Since then, it has undergone refinement, leading to the creation of several grades with variations in viscosity and solubility. One of its primary advantages is its ability to form stable solutions that do not rely on high concentrations of other thickeners. This properties create more efficient formulations while ensuring low caloric content in food products and effective delivery of active pharmaceutical ingredients.

Moreover, HPMC exhibits remarkable thermal stability, which means it can withstand various processing conditions without losing its characteristics. This stability is particularly crucial for maintaining product integrity during manufacturing and storage. Industries value HPMC not only for its functionality but also for its safety profile, as it is non-toxic and generally recognized as safe (GRAS) by the FDA. Due to these features, HPMC continues to be a preferred choice across various sectors, ensuring that formulations perform optimally while meeting consumer demands.

| Característica | Descripción |

|---|---|

| Chemical Nature | Semi-synthetic cellulose derivative |

| Aplicaciones | Productos farmacéuticos, alimentos, cosméticos |

| Ventajas | Thermal stability, non-toxic, versatile |

2. What Does the HPMC Solubility Chart Show?

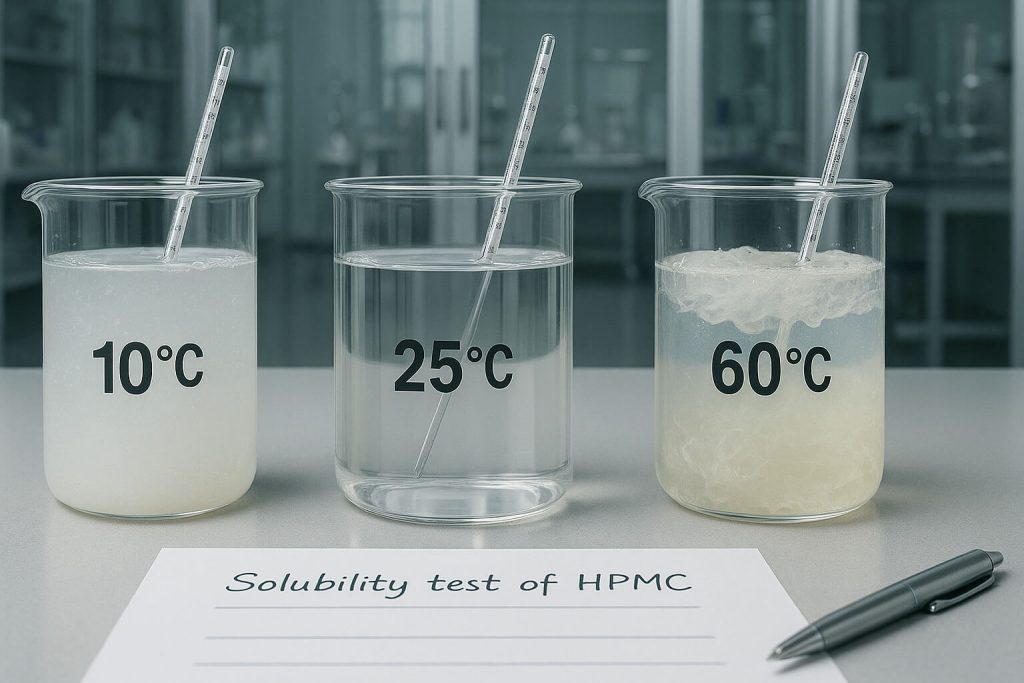

The HPMC solubility chart serves as a pivotal tool for formulators working with this versatile polymer. What’s the real story? At its core, the chart provides a visual representation of solubility across various grades of HPMC in different solvents and under varying temperature conditions. This is crucial for professionals seeking to determine the best formulation strategies for their products.

The solubility chart typically includes multiple HPMC grades, classified according to their viscosity and molecular weight. For instance, higher viscosity HPMC grades may exhibit a range of solubility based on temperature, potentially creating a more viscous solution upon dissolution. This characteristic is essential for applications that require specific textural elements, such as in the food or personal care industry.

Furthermore, the solubility chart can help identify threshold points where HPMC starts to dissolve and the temperatures that yield optimum solubility. This is particularly valuable in pharmaceutical applications, where correct dosage forms often depend on precise solubility factors. For example, suppose a formulation requires HPMC for sustained release. In that case, the chart can reveal which grade of HPMC to select to ensure effective drug delivery.

Understanding the solubility chart not only facilitates better formulation practices but also guides manufacturers in troubleshooting issues such as cloudiness or inconsistent consistency in their products. Consequently, the HPMC solubility chart is an indispensable resource for ensuring successful formulations across various applications.

| Parámetro | Descripción |

|---|---|

| Solvent Types | Aqueous vs. organic solvents |

| Rango de temperatura | Optimal conditions for solubility |

| Implications for Viscosity | Dependence on HPMC grade and intended use |

3. What Factors Affect HPMC Solubility?

Several factors influence the solubility of HPMC, which is crucial for effective formulation. This is where it gets interesting: understanding these elements allows manufacturers to optimize their use of HPMC effectively.

First and foremost is temperature. Increasing the temperature generally enhances solubility. For example, warm water can dissolve HPMC more rapidly compared to cold water, which is essential during production when rapid mixing is required. Conversely, colder temperatures can lead to incomplete solubility and clumping, resulting in a subpar final product.

Next, pH levels can greatly impact HPMC solubility. HPMC is stable across a range of pH, but extreme values may decrease its ability to dissolve fully. For instance, very acidic or alkaline conditions can alter the polymer’s structure, leading to reduced performance in formulations. This is particularly relevant in pharmaceuticals, where specific pH levels must be maintained to ensure drug stability.

Additionally, the molecular weight of HPMC plays a significant role in solubility. Higher molecular weight HPMC grades can impact the viscosity of the solution more than lower molecular weight grades. Consequently, understanding which molecular weight to use can prevent issues with stirring and mixing during the formulation process.

By recognizing these factors, formulators can predict how HPMC will react under various conditions and select the appropriate grades for optimal solubility in their products, ultimately improving the quality and effectiveness of formulations.

| Factor | Influence on Solubility |

|---|---|

| Temperatura | Higher temps increase solubility |

| niveles de pH | El pH extremo puede reducir la solubilidad. |

| Peso molecular | Affects viscosity and mixing characteristics |

4. How Do Different Grades of HPMC Affect Solubility?

When it comes to the different grades of HPMC, each possesses unique properties that affect its solubility. But here’s the kicker: knowing which grade to use can dramatically impact product performance.

HPMC comes in varying viscosities, typically classified into low, medium, and high viscosity grades. Low-viscosity grades dissolve quickly, forming a thin solution that is ideal for applications that require minimal thickness, such as in beverages or light creams. In contrast, high-viscosity grades are better for applications demanding thicker textures, such as thickening sauces or creams.

The specific molecular weight of the HPMC also dictates how it behaves in a solvent. For example, higher molecular weight HPMC forms more viscous solutions and might require longer or more vigorous mixing to dissolve efficiently. This characteristic is critical in pharmaceuticals, where uniformity in drug delivery is paramount. A mismatch in viscosity could lead to inconsistent dosing and efficacy.

It’s also important to note that the solubility behavior can be affected by the nature of the solvent being used. For instance, some HPMC grades dissolve well in water while exhibiting poor solubility in organic solvents. This property necessitates careful formulation planning, especially in industries that leverage multiple solvent systems.

By being aware of these differences, formulators can optimize their use of HPMC, ensuring that they select the most effective grade for their particular applications, thus enhancing product quality and performance.

| Grado HPMC | Características de viscosidad |

|---|---|

| Baja viscosidad | Quick dissolution, minimal thickening |

| Viscosidad media | Balanced texture, versatile applications |

| Alta viscosidad | Creates thick solutions, requires vigorous mixing |

5. What Are Common Applications of HPMC in Industry?

HPMC finds applications across several industries, each taking advantage of its unique properties. What’s the real story? It has established itself as an essential ingredient in pharmaceuticals, food production, and personal care products.

In the pharmaceutical industry, HPMC is primarily used as a binder and coating agent in tablets and capsules. Its ability to create controlled-release formulations allows for sustained delivery of active pharmaceutical ingredients, and it helps ensure a consistent dosage with each administration. A notable example is its application in extended-release medication, where it regulates the release rate of drugs, enhancing therapeutic efficacy.

In the food industry, HPMC serves as a thickening agent and emulsifier in various products, from sauces to dairy items. It enhances the mouthfeel and texture of food without adding calories, making it a preferred ingredient in many low-fat and reduced-calorie formulations. For example, in salad dressings, HPMC aids in keeping the oil and vinegar phases uniform, allowing for a creamy texture that consumers appreciate.

The personal care sector also leverages HPMC’s properties, particularly in lotions, creams, and gels. Its stabilizing capabilities prevent ingredient separation, ensuring a smooth, consistent product that performs effectively. In sunscreens, HPMC helps maintain a thick but easily spreadable consistency, which is essential for uniform protection.

The varied applications of HPMC illustrate its multifaceted nature, allowing it to cater to the distinct requirements of different industries and contributing to product innovation and quality in health and consumer goods.

| Industria | Aplicaciones comunes |

|---|---|

| Productos farmacéuticos | Binders and coatings in tablets/capsules |

| Industria alimentaria | Thickeners and emulsifiers in sauces |

| Cuidado personal | Stabilizers in creams and lotions |

6. How to Use the HPMC Solubility Chart Effectively?

Effectively using the HPMC solubility chart can greatly streamline the formulation process. Ready for the good part? Following best practices when interpreting the chart ensures optimal formulation results.

First, begin by familiarizing yourself with the different grades of HPMC and their solubility characteristics. Each grade has specific requirements regarding temperature and pH levels for optimal dissolution. Therefore, understanding these parameters is essential for accurate use of the chart.

When approaching formulation, always start with a lower concentration of HPMC. Monitoring how the solution behaves as you increase the concentration can help you avoid excessive thickness or variations in texture. Additionally, it allows you to note any changes in solubility as other ingredients are introduced.

Always keep an eye on the temperature during the mixing process. Utilizing warm water can enhance solubility and efficiency in achieving the desired viscosity. It’s common to combine the HPMC with other dry ingredients before introducing liquid to achieve a more homogeneous mixture.

If issues arise during mixture, refer back to the solubility chart. This chart can assist in troubleshooting by revealing whether a particular grade or concentration is unsuitable for the application. Testing small batches will also provide insight into formulation stability and behavior before proceeding to larger-scale production.

By applying these strategies, formulators can harness the full potential of the HPMC solubility chart, ensuring successful product outcomes.

| Paso | Acción recomendada |

|---|---|

| Familiarize with Grades | Review solubility characteristics of each grade |

| Start Low | Use lower concentrations to gauge behavior |

| Monitor Temperature | Ensure optimal dissolution conditions |

7. What Are the Limitations of the HPMC Solubility Chart?

While the HPMC solubility chart is a valuable resource, it possesses limitations that users should be aware of. But here’s the kicker: understanding these limitations can prevent costly formulation errors and improve overall product quality.

One significant limitation lies in the fact that the chart represents ideal conditions. Real-world applications may vary due to numerous external factors such as ingredient variability, environmental conditions, and processing techniques. For example, if a specific batch of HPMC has a slightly different molecular weight than the chart suggests, the solubility could diverge from expectations.

Additionally, some formulations require the interaction of multiple ingredients that the solubility chart cannot account for. For instance, if HPMC is combined with certain acids or organic solvents, its behavior may change significantly, potentially leading to poor solubility or destabilized mixtures.

Another important point is that the chart does not account for the kinetics of solubility. It can guide users on the maximum solubility of a grade but does not provide information on how quickly it will reach that point during mixing or processing. Faster dissolution times may be essential for efficient production, and relying solely on the chart can lead to delays.

Recognizing these limitations ensures that formulators do not depend solely on the solubility chart but also conduct empirical tests to confirm solubility and suitability in their specific applications.

| Limitación | Descripción |

|---|---|

| Ideal Conditions | Chart reflects optimal conditions, not real-world variances |

| Interacciones de ingredientes | Multi-ingredient formulations may behave unpredictably |

| Kinetics of Solubility | Chart does not address the rate of solubility |

8. How Does HPMC Interact with Other Ingredients?

Understanding how HPMC interacts with other ingredients is crucial for achieving optimal product performance. This is where it gets interesting: HPMC is known for its compatibility with a wide array of substances, yet each interaction can yield different results in formulation effectiveness.

When combined with other polymers or stabilizers, HPMC can enhance the viscosity and texture of formulations. For instance, when added to gels or creams, it can work synergistically with ingredients like Carbomer, resulting in a product with improved stability and aesthetic appeal. This is important for developing personal care items where user experience is paramount.

On the other hand, HPMC can also interact adversely with certain ingredients, such as divalent salts. These may cause HPMC to precipitate or gel, affecting the overall viscosity of the solution. Recognizing these potential incompatibilities is essential for formulators to avoid issues in stability and performance.

In addition, when using HPMC in food applications, it has a favorable reaction with other ingredients, such as emulsifiers and thickeners. In salad dressings, for instance, it helps maintain oil and water integration, resulting in a consistent texture that consumers expect.

Knowing how HPMC reacts with various ingredients allows chemists and formulators to craft better products and troubleshoot issues effectively, ultimately leading to improved formulations that meet consumer and market demands.

| Interaction Type | Resultado |

|---|---|

| Polymer Compatibility | Enhanced viscosity and stability |

| Incompatibilities | Potential precipitation or gel formation |

| Aplicaciones alimentarias | Improved emulsification and texture consistency |

9. What Trends Are Influencing HPMC Use and Solubility?

As industries evolve, new trends shape the application and the demand for HPMC. Ready for the good part? One significant trend is the growing consumer preference towards natural and clean-label products. Manufacturers are increasingly seeking ingredients like HPMC, as it maintains product safety while enhancing formulation performance.

Another important trend is sustainability. The push for eco-friendly practices encourages companies to explore biodegradable options. HPMC, being derived from plant cellulose, naturally aligns with these sustainability goals, making it a prime candidate for environmentally conscious brands. The production process itself has also seen a shift towards reducing energy consumption and waste, further making HPMC a favorable ingredient choice.

Technological advancements are driving innovation in the formulation of new products. For example, as newer forms of HPMC are developed, the solubility and performance in various applications continue to improve, opening up potential uses in fields such as drug delivery and food processing. The ability to create highly effective controlled-release formulations using HPMC propels it to the forefront of pharmaceutical research.

As these trends progress, the demand for improved solubility and performance of HPMC will likely encourage manufacturers to keep experimenting with formulations, ultimately benefiting end consumers through innovative product offerings.

| Tendencia | Impact on HPMC Usage |

|---|---|

| Consumer Preference | Drives demand for natural, clean-label products |

| Sostenibilidad | Encourages biodegradable ingredient exploration |

| Innovaciones tecnológicas | Enhances formulation capabilities and applications |

10. Where Can Companies Source High-Quality HPMC and Solubility Charts?

Sources for high-quality HPMC and reliable solubility charts are crucial for manufacturers looking to enhance their formulations. What’s the real story? Identifying reputable suppliers is the first step in obtaining quality HPMC. Companies should seek suppliers that adhere to Good Manufacturing Practices (GMP) and have a well-established reputation in the industry.

Another avenue is to refer to established chemical databases and industry publications that provide access to solubility charts. Many reputable suppliers also have their own solubility charts available, detailing the solubility behavior of various HPMC grades in different solvents.

Attending industry trade shows and exhibitions can also be beneficial for sourcing HPMC and establishing connections with suppliers. These events often provide opportunities to engage in discussions with experts and learn about the latest research and innovations in using HPMC in formulations.

Additionally, companies should conduct thorough evaluations of potential suppliers, checking for customer testimonials, product specifications, and any certifications that demonstrate product quality. Engaging with suppliers that provide technical support can also enhance formulation capabilities, as they offer insights on optimizing the use of HPMC.

By leveraging these resources, companies can ensure they are sourcing high-quality HPMC while gaining access to valuable solubility charts that will assist in their formulation processes.

| Sourcing Strategy | Descripción |

|---|---|

| Proveedores de confianza | Seek out suppliers following GMP standards |

| Publicaciones de la industria | Access chemical databases for solubility data |

| Trade Shows and Expos | Network and learn about new products |

Sección de preguntas frecuentes

Pregunta 1: ¿Qué es HPMC?

HPMC (Hydroxypropyl Methylcellulose) is a cellulose-derived polymer widely used for its thickening, binding, and emulsifying properties across various industries.

Pregunta 2: How does the HPMC solubility chart work?

The HPMC solubility chart visually represents how different grades of HPMC dissolve in various solvents and temperatures, guiding formulators in their ingredient selection.

Pregunta 3: What factors influence the solubility of HPMC?

Factors affecting HPMC solubility include temperature, pH levels, and the molecular weight of the HPMC grade being utilized.

Pregunta 4: What are the limitations of the HPMC solubility chart?

The solubility chart reflects ideal scenarios and may not apply to real-world formulations, as actual ingredient variability, environmental conditions, and processing techniques can affect solubility.

Pregunta 5: Where can I find reliable sources for HPMC and solubility charts?

Reliable HPMC can be sourced from suppliers adhering to GMP, while industry databases and publications often provide access to accurate solubility charts, alongside networking at trade events.