L'hydroxypropylméthylcellulose (HPMC) est un polymère polyvalent qui joue un rôle important dans divers secteurs, de l'industrie pharmaceutique à la construction en passant par l'agroalimentaire. Connue pour sa capacité à se dissoudre dans l'eau et à former des gels, l'HPMC possède des propriétés uniques qui en font un ingrédient précieux dans de nombreuses formulations. Cet article explore les principales propriétés de l'HPMC et son utilisation dans différentes applications industrielles. De l'amélioration de la qualité des produits à la préservation de l'environnement, comprendre les avantages de l'HPMC est essentiel pour les professionnels du secteur.

1. Qu'est-ce que l'HPMC et comment fonctionne-t-il dans l'industrie ?

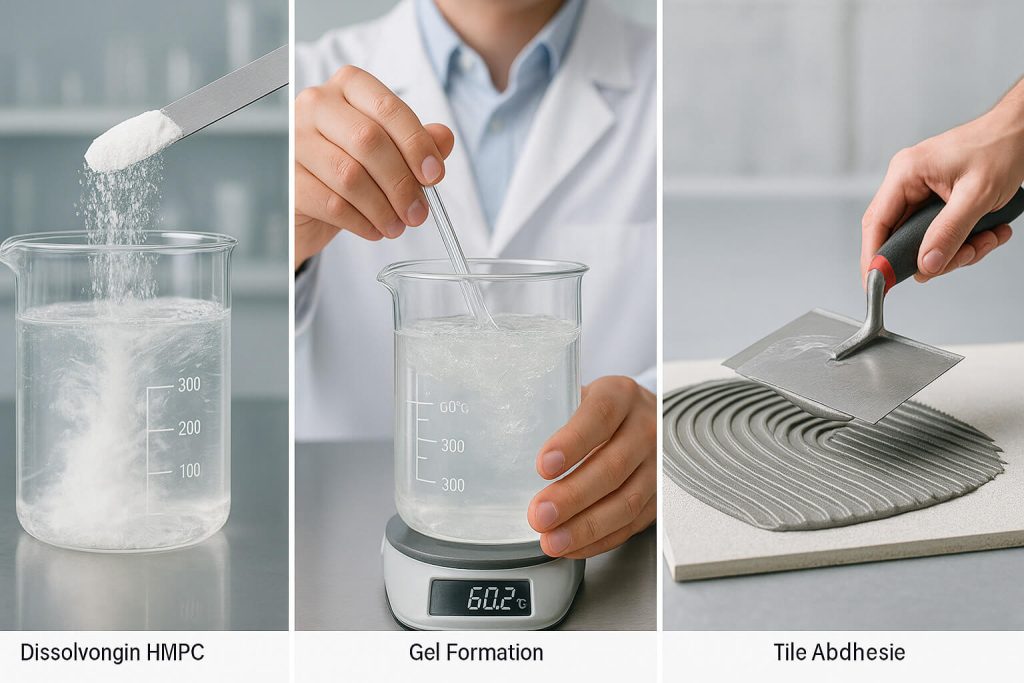

L'hydroxypropylméthylcellulose (HPMC) est un polymère semi-synthétique obtenu par modification de la cellulose, une matière végétale naturelle. Grâce à l'introduction de groupes hydroxypropyle et méthyle, l'HPMC devient hydrosoluble et forme des substances gélatineuses idéales pour diverses applications. Cette modification chimique confère à l'HPMC polyvalence et fonctionnalité, lui permettant d'effectuer un large éventail de fonctions, telles que l'épaississement, l'émulsification et la liaison.

En milieu industriel, la capacité de l'HPMC à se dissoudre dans l'eau froide comme dans l'eau chaude en fait un excellent choix pour les applications pharmaceutiques, alimentaires et de construction. Il est utilisé dans les formulations de comprimés comme liant, stabilisant et agent à libération contrôlée dans l'industrie pharmaceutique. Dans la production alimentaire, l'HPMC agit comme épaississant et émulsifiant, garantissant aux produits la texture et la consistance souhaitées. De plus, dans la construction, ses propriétés de rétention d'eau et d'adhérence en font un ingrédient essentiel des mortiers et des adhésifs.

En améliorant les performances des produits et en garantissant une qualité constante, le rôle de l'HPMC dans les applications industrielles est indéniable. La compréhension de ses propriétés aide les fabricants à optimiser leurs formulations, à améliorer la stabilité de leurs produits et à répondre aux exigences de divers secteurs.

| Industrie | Applications | Rôle du HPMC |

|---|---|---|

| Médicaments | Liants, agents à libération contrôlée | Cohérence, libération contrôlée du médicament |

| Nourriture | Émulsifiants, stabilisants, épaississants | Texture, consistance, durée de conservation |

| Construction | Mortiers, colles | Rétention d'eau, maniabilité, adhérence |

2. Quelles sont les principales propriétés physiques et chimiques du HPMC ?

Les propriétés clés de l'HPMC en font un choix privilégié pour diverses applications industrielles. Parmi ces propriétés, on peut citer : solubilité dans l'eau, contrôle de la viscosité, formation de gel, stabilité thermique, et biodégradabilitéChaque propriété joue un rôle crucial dans la détermination de la fonctionnalité du polymère dans différentes industries.

Solubilité dans l'eau C'est peut-être la propriété la plus importante de l'HPMC. Elle permet au polymère de se dissoudre aussi bien dans l'eau froide que chaude, ce qui le rend idéal pour les produits exigeant une texture et une stabilité uniformes. Qu'il soit utilisé dans les produits pharmaceutiques pour former une matrice de comprimés ou dans les aliments pour stabiliser les émulsions, la solubilité de l'HPMC garantit des résultats constants.

Contrôle de la viscosité est une autre caractéristique essentielle. L'HPMC peut modifier la viscosité des solutions, un atout précieux dans les formulations pharmaceutiques et alimentaires. Dans le secteur pharmaceutique, il permet de contrôler la fluidité des principes actifs des comprimés, tandis que dans le secteur alimentaire, il permet d'obtenir l'épaisseur idéale pour les sauces et les vinaigrettes.

Capacité de formation de gel L'HPMC est particulièrement utile dans les formulations à libération contrôlée de médicaments. En formant une matrice gélifiée, elle régule la vitesse de libération des principes actifs, garantissant une libération lente et régulière du médicament au fil du temps.

Stabilité thermique garantit que le HPMC conserve ses propriétés fonctionnelles lorsqu'il est exposé à des températures variables, ce qui est particulièrement bénéfique dans les industries alimentaires et de la construction.

Enfin, Biodégradabilité L'HPMC constitue une option écologique pour les industries en quête de solutions durables. Face à l'augmentation des préoccupations environnementales, la capacité de l'HPMC à se décomposer naturellement constitue un argument de vente essentiel.

| Propriété | Fonctionnalité | Application |

|---|---|---|

| Solubilité dans l'eau | Se dissout facilement dans l'eau | Produits pharmaceutiques, alimentation, construction |

| Contrôle de la viscosité | Ajuste l'épaisseur des solutions | Produits pharmaceutiques, aliments |

| Capacité de formation de gel | Forme des gels pour une libération contrôlée | Produits pharmaceutiques, construction |

| Stabilité thermique | Maintient la stabilité à différentes températures | Produits pharmaceutiques, aliments |

| Biodégradabilité | Se décompose naturellement | Applications respectueuses de l'environnement |

3. Comment l’HPMC est-il utilisé dans les formulations pharmaceutiques ?

Le rôle de l'HPMC dans l'industrie pharmaceutique est indispensable. Il est largement utilisé comme liant Dans les formulations de comprimés, où il contribue à lier les principes actifs, garantissant ainsi leur intégrité structurelle. Sans HPMC, les comprimés risquent de s'effriter ou de ne pas délivrer efficacement le principe actif. En formant une masse uniforme et cohésive, l'HPMC garantit une répartition homogène des principes actifs et l'intégrité du comprimé lors de sa manipulation et de son ingestion.

Une autre fonction clé de l’HPMC dans les produits pharmaceutiques est sa capacité à contrôler la libération des médicaments. Formulations à libération contrôlée sont essentiels pour garantir la libération progressive d'un médicament au fil du temps, procurant ainsi des effets thérapeutiques durables. L'HPMC agit comme une matrice qui retient le médicament et régule sa libération, assurant une libération régulière et contrôlée tout au long de la journée.

De plus, le HPMC est utilisé dans produits topiques et transdermiquesDans ces applications, l'HPMC forme des gels qui contiennent des principes actifs pharmaceutiques dans une matrice stable, permettant une absorption cutanée efficace. Sa capacité à former des gels garantit l'intégrité du produit et une libération constante des principes actifs au fil du temps.

| Demande pharmaceutique | Fonction | Avantage |

|---|---|---|

| Liant | Maintient les ingrédients actifs ensemble | Assure l'intégrité du comprimé et une libération uniforme du médicament |

| libération contrôlée | Régule la libération de médicaments | Effet thérapeutique stable, fréquence de dosage réduite |

| Gels et produits topiques | Forme des matrices stables pour les produits topiques | Absorption cutanée efficace, stabilité |

4. Quels sont les avantages de l’HPMC dans la production d’aliments et de boissons ?

Dans l’industrie alimentaire, l’HPMC est principalement utilisé comme épaississant, émulsifiant, et stabilisateurSa polyvalence dans la modification de la texture et de la consistance des produits alimentaires le rend essentiel dans de nombreuses formulations. épaississantL'HPMC améliore la texture et la viscosité des produits tels que les sauces, les soupes et les vinaigrettes. En augmentant la viscosité, l'HPMC offre une texture optimale, évitant ainsi que le produit ne se sépare ou ne devienne trop liquide.

Émulsification L'HPMC joue également un rôle essentiel dans l'alimentation. Il est utilisé dans des produits comme la mayonnaise, les vinaigrettes et les glaces, où il contribue à maintenir les phases huileuse et aqueuse ensemble. Sans HPMC, ces produits subiraient une séparation de phase, ce qui entraînerait des textures irrégulières et une mauvaise expérience consommateur.

Stabilisation est tout aussi important dans la production alimentaire. Dans des produits comme les aliments sans gluten et les formulations végétales, l'HPMC contribue à maintenir la consistance et la texture, offrant un produit qui imite les formulations traditionnelles tout en offrant les propriétés fonctionnelles nécessaires. L'HPMC prolonge également la durée de conservation des produits alimentaires, les empêchant de se détériorer prématurément.

| Application alimentaire | Fonction | Avantage |

|---|---|---|

| Épaississant | Augmente la viscosité des sauces et des soupes | Apporte de la texture, empêche la séparation |

| Émulsifiant | Maintient l'huile et l'eau en suspension | Assure une texture uniforme et une stabilité |

| Stabilisateur | Maintient la consistance, prolonge la durée de conservation | Préserve la qualité du produit, améliore la texture |

5. Comment le HPMC est-il utilisé dans l’industrie de la construction ?

Dans le secteur de la construction, le HPMC joue un rôle important en tant que additif dans mortiers à sec, pansements, et colles à carrelageSa fonction première est d’améliorer la maniabilité de ces matériaux, ce qui les rend plus faciles à mélanger, à appliquer et à étaler. Les mortiers et enduits peuvent souvent devenir trop épais ou difficiles à travailler, mais l'HPMC garantit un mélange lisse et homogène, facile à manipuler.

Une autre fonction importante du HPMC est rétention d'eauDans les mortiers et enduits secs, l'HPMC contribue à retenir l'eau, empêchant ainsi le mélange de sécher trop rapidement pendant l'application. Cela permet un durcissement optimal, garantissant une prise correcte du matériau et la formation d'adhérences solides. Sans une rétention d'eau adéquate, le matériau pourrait sécher prématurément, entraînant des fissures et une diminution de sa résistance.

Amélioration de l'adhérence L'HPMC présente un autre avantage dans la construction. Il améliore l'adhérence des colles à carrelage, garantissant ainsi une bonne tenue des carreaux une fois posés. Il en résulte des installations plus durables et moins de problèmes d'entretien à long terme.

| Demande de permis de construire | Fonction | Avantage |

|---|---|---|

| Mortiers à sec | Améliore la maniabilité, empêche l'agglutination | Mélange et application faciles |

| Pansements | Améliore la rétention d'eau | Assure un bon durcissement, prévient les fissures |

| Adhésifs | Améliore l'adhérence et le collage | Lien solide et durable |

6. Comment le HPMC peut-il contribuer aux pratiques durables et à la fabrication verte ?

Face aux préoccupations environnementales croissantes, le HPMC offre plusieurs avantages clés aux industries à la recherche d’alternatives plus durables. Le HPMC est biodégradable, ce qui signifie qu'il se décompose naturellement sans nuire à l'environnement. Cette biodégradabilité fait de l'HPMC une option intéressante pour les entreprises souhaitant réduire leur empreinte environnementale.

Dans construction, HPMC contribue à matériaux de construction écologiques En remplaçant les produits chimiques synthétiques potentiellement nocifs pour l'environnement, l'utilisation de HPMC contribue à réduire la dépendance aux ingrédients dérivés du pétrole, favorisant ainsi la durabilité dans la construction.

Dans le industrie alimentaire, HPMC est un alternative à base de plantes aux ingrédients d'origine animale comme la gélatine, répondant ainsi à la demande croissante de produits végétaliens et végétariens. En remplaçant ces ingrédients par de l'HPMC, les fabricants peuvent proposer des options alimentaires plus durables et éthiques, qui s'adressent à un public plus large.

| Avantage environnemental | Description | Application |

|---|---|---|

| Biodégradabilité | Se décompose naturellement dans l'environnement | Construction verte, production alimentaire respectueuse de l'environnement |

| Écologique | Alternative durable aux polymères synthétiques | Matériaux de construction écologiques, options alimentaires durables |

7. Comment le HPMC peut-il être personnalisé pour différentes utilisations industrielles ?

L'une des caractéristiques remarquables de l'HPMC est sa personnalisation pour diverses applications industrielles. Les fabricants peuvent modifier viscosité, taux de dissolution, et degré de substitution pour adapter le HPMC à des besoins spécifiques.

Dans le industrie pharmaceutique, en ajustant le taux de dissolution Permet la création de formulations médicamenteuses à libération contrôlée. Les fabricants peuvent ainsi concevoir des médicaments libérant progressivement leurs principes actifs, améliorant ainsi les résultats thérapeutiques et réduisant la fréquence des prises.

Dans le industrie alimentaire, en ajustant le viscosité L'utilisation de HPMC garantit que le produit possède la texture souhaitée, qu'il s'agisse d'épaissir une soupe ou d'émulsionner une vinaigrette. construction, personnaliser le degré de substitution aide à améliorer l'adhérence et la maniabilité des mortiers et adhésifs à sec.

| Aspect personnalisation | Fonction | Avantage |

|---|---|---|

| Contrôle de la viscosité | Ajuste l'épaisseur des solutions | Des performances sur mesure pour différents secteurs d'activité |

| Taux de dissolution | Contrôle la libération du médicament ou le taux d'émulsification | Libération prolongée, texture homogène |

| Degré de substitution | Influence la solubilité et la formation de gel | Des propriétés adaptées à des besoins spécifiques |

8. Quels sont les défis courants liés à l’utilisation de l’HPMC ?

Bien que l'HPMC offre de nombreux avantages, son utilisation présente quelques difficultés. L'une des plus courantes est dissolution incohérenteLorsque vous travaillez avec de gros lots, il peut être difficile de garantir que le HPMC se dissout uniformément, ce qui peut entraîner une qualité de produit inégale.

Sensibilité à la température est un autre problème. Bien que l'HPMC soit stable dans une certaine plage de températures, chaleur excessive peut dégrader le polymère et réduire son efficacité. Il est donc essentiel de maintenir les températures de traitement adéquates.

Enfin, problèmes de coûts et de chaîne d'approvisionnement peuvent avoir un impact sur la disponibilité et le prix de l'HPMC. Selon la source de la cellulose et son degré de modification, les fluctuations de prix et de disponibilité peuvent affecter le coût global de production.

| Défi | Cause | Solution |

|---|---|---|

| Dissolution incohérente | Mélange incorrect, rapport eau/polymère | Assurer des techniques de dissolution appropriées et un contrôle de qualité |

| Sensibilité à la température | Dégradation à haute température | Maintenir des conditions de traitement optimales |

| Problèmes de chaîne d'approvisionnement | Fluctuations des prix des matières premières |

et disponibilité | Sourcez des fournisseurs fiables, optimisez la production |

9. Existe-t-il des alternatives au HPMC dans diverses applications ?

Bien que le HPMC soit très efficace, il existe des polymères alternatifs qui remplissent des fonctions similaires. Méthylcellulose (MC) est une alternative connue pour sa capacité à former des gels à des températures plus élevées. Cependant, cette capacité limite sa polyvalence par rapport à l'HPMC, ce qui en fait un choix privilégié dans de nombreuses applications.

Carboxyméthylcellulose (CMC) Il s'agit d'une autre alternative, notamment utilisée pour la modification de la viscosité. La CMC est courante dans les industries agroalimentaire et pharmaceutique, mais elle ne possède pas les capacités de gélification qui rendent l'HPMC plus adaptable.

Malgré l’existence de ces alternatives, le HPMC reste un polymère de référence en raison de sa combinaison de propriétés, notamment solubilité dans l'eau, formation de gel, et contrôle de la viscosité.

| Alternative | Caractéristiques principales | Application |

|---|---|---|

| Méthylcellulose | Formation de gel à des températures plus élevées | Alimentation, produits pharmaceutiques |

| Carboxyméthylcellulose | Contrôle de la viscosité | Alimentation, produits pharmaceutiques |

| HPMC | Solubilité dans l'eau, formation de gel | Produits pharmaceutiques, construction, alimentation |

Conclusion

En conclusion, l'hydroxypropylméthylcellulose (HPMC) est un polymère polyvalent et essentiel utilisé dans de nombreuses industries pour ses propriétés uniques. solubilité dans l'eau, contrôle de la viscosité, capacité de formation de gel, et stabilité thermique en font un ingrédient précieux dans les secteurs pharmaceutique, alimentaire et de la construction. Alors que les industries cherchent à adopter des pratiques plus durables, les HPMC biodégradabilité et nature respectueuse de l'environnement Cela ne fait qu'augmenter sa valeur. Malgré des défis tels que la sensibilité à la température et la variabilité de la chaîne d'approvisionnement, les avantages du HPMC l'emportent largement sur ses inconvénients, ce qui en fait un choix incontournable pour les fabricants du monde entier.

FAQ

Q1:Qu'est-ce que l'hydroxypropylméthylcellulose (HPMC) ?

Le HPMC est un polymère dérivé de la cellulose utilisé comme liant, émulsifiant et stabilisant dans diverses industries telles que les produits pharmaceutiques, l'alimentation et la construction.

Q2:Comment fonctionne l'HPMC dans les applications pharmaceutiques ?

Le HPMC sert de liant dans les comprimés et aide à contrôler la libération des ingrédients actifs dans les formulations à libération contrôlée, garantissant une administration constante du médicament.

Q3:Quel rôle joue l'HPMC dans l'industrie alimentaire ?

Le HPMC est utilisé comme épaississant, émulsifiant et stabilisant, améliorant la texture et la consistance des produits alimentaires et agissant comme une alternative végétalienne aux ingrédients traditionnels comme la gélatine.

T4:Comment le HPMC profite-t-il au secteur de la construction ?

Dans la construction, le HPMC améliore la maniabilité et l’adhérence des mortiers et des adhésifs, tout en aidant à retenir l’eau pour un meilleur durcissement et une meilleure durabilité.

Q5:Existe-t-il des alternatives à l’HPMC ?

Des alternatives comme la méthylcellulose et la carboxyméthylcellulose offrent des propriétés similaires, mais l'HPMC reste le choix préféré en raison de sa fonctionnalité polyvalente et de ses performances dans un large éventail d'industries.