Hydroxypropyl Methylcellulose (HPMC) is a versatile cellulose derivative known for its wide range of applications across various industries. Given its multifunctionality, HPMC serves as a critical ingredient in pharmaceuticals, food products, cosmetics, construction materials, and more. This article explores the diverse uses and benefits of Hydroxypropyl Methylcellulose while addressing its significance and relevance for businesses in these sectors. By understanding the myriad applications of HPMC, decision-makers can leverage this substance effectively to enhance product performance and consumer satisfaction.

1. What is Hydroxypropyl Methylcellulose?

Hydroxypropyl Methylcellulose (HPMC) is a chemical compound made from cellulose, which is derived from plant fibers. It is a non-ionic, water-soluble polymer that plays an important role in many formulations. But here’s the kicker: the chemical structure of HPMC allows it to not only dissolve in water but also form gels, making it an ideal thickening agent for a variety of applications.

The historical development of HPMC dates back to the early 20th century when cellulose ethers were first introduced in industrial applications. Since then, its unique properties, such as viscosity control and film-forming capabilities, have been harnessed in multiple sectors.

One of the most significant characteristics of HPMC is its ability to retain water, which enhances the texture and stability of products. This water retention is vital in numerous industries where the moisture level of a product must be controlled, especially in pharmaceuticals and food.

Moreover, Hydroxypropyl Methylcellulose is odorless, tasteless, and non-toxic, making it suitable for food and pharmaceutical applications where safety and sensory properties are crucial. Its compatibility with various active ingredients also makes HPMC a favorite in complex formulations. As industries continue evolving, so too does the role of HPMC, driving innovations in formulation technologies.

| Characteristic | Details |

|---|---|

| Definition | Water-soluble cellulose derivative |

| Properties | Thickening, gelling, and water retention |

| Applications | Pharmaceuticals, food, cosmetics, construction |

2. How is Hydroxypropyl Methylcellulose Used in Pharmaceuticals?

In the pharmaceutical sector, Hydroxypropyl Methylcellulose is integral as an excipient in numerous drug formulations. What’s the real story? Its ability to control the release of active pharmaceutical ingredients (APIs) makes HPMC an invaluable asset in medication development.

For instance, tablet formulations often include HPMC to improve hardness and control drug release rates. In controlled-release tablets, this polymer creates a barrier around the drug, resulting in a gradual release of the medicine into the bloodstream. Research has shown that HPMC can effectively extend the release of certain drugs, allowing for less frequent dosing and improved patient compliance.

Moreover, HPMC is frequently used in emulsions and suspensions to stabilize the formulation. It prevents sedimentation, ensuring that the active ingredients remain evenly distributed throughout the liquid. This stabilizing feature is particularly important in topical applications, such as creams and gels, where consistent application is critical for efficacy.

Furthermore, HPMC helps enhance the bioavailability of poorly soluble drugs. By modifying the viscosity of the formulation, it facilitates better absorption in the gastrointestinal tract. A study highlighted that formulations incorporating HPMC exhibited improved solubility and bioavailability compared to traditional formulations lacking in this polysaccharide.

Ultimately, the incorporation of Hydroxypropyl Methylcellulose in various pharmaceutical applications not only enhances the performance of medications but also addresses the growing concerns of tailored drug delivery systems.

| Demande pharmaceutique | Rôle du HPMC |

|---|---|

| Comprimés à libération contrôlée | Maintains release rates of active ingredients |

| Emulsions and Suspensions | Stabilizes formulations to prevent separation |

| Bioavailability Improvement | Enhances absorption of poorly soluble drugs |

3. What are the Food Industry Applications of Hydroxypropyl Methylcellulose?

Hydroxypropyl Methylcellulose has found extensive applications in the food industry. Ready for the good part? Its ability to enhance texture, stability, and overall quality makes it a popular choice among food manufacturers.

One primary use of HPMC in food products is as a thickening agent. In sauces, dressings, and soups, HPMC provides the desired viscosity, resulting in a more appealing mouthfeel for consumers. It also stabilizes emulsions, preventing the separation of oil and water phases in products like mayonnaise and salad dressings. This stability is crucial for ensuring a consistent consumer experience.

In addition to thickening, HPMC is used as a fat replacer in low-fat and reduced-calorie food formulations. By mimicking the creamy texture and mouthfeel of fats, it allows manufacturers to develop healthier alternatives without sacrificing flavor or acceptance. This property is particularly important in the development of gluten-free products, where HPMC mimics the structural qualities that gluten typically provides.

Moreover, regulatory compliance is critical in the food industry, and HPMC has been recognized as Generally Recognized as Safe (GRAS) by the FDA, which facilitates its use across a variety of food categories.

Recent studies show that incorporating Hydroxypropyl Methylcellulose can extend the shelf life of food products by maintaining moisture and texture. Therefore, these functionalities enable companies to cater to health-conscious consumers while also meeting quality standards for food safety.

| Type d'application | Rôle du HPMC |

|---|---|

| Sauces and Condiments | Provides viscosity and stabilizes emulsions |

| Low-Fat Products | Acts as a fat replacer to enhance texture |

| Produits sans gluten | Mimics gluten structure for better consistency |

4. How is Hydroxypropyl Methylcellulose Applied in Cosmetics?

In the realm of cosmetics and personal care, Hydroxypropyl Methylcellulose serves as a multifunctional ingredient with a variety of applications. This is where it gets interesting. HPMC is prized for its properties as a thickener, emulsifier, and film-former, ensuring that products meet consumer expectations for quality and performance.

Many skincare products utilize HPMC to enhance texture and stability. In creams and lotions, it helps achieve a desirable thickness and consistency, promoting a luxurious feel during application. The smooth application and sensory experience significantly influence consumer preference, thus making HPMC a valuable asset for brands looking to create high-quality products.

Moreover, HPMC’s film-forming capabilities contribute to its use in makeup products. For example, in foundations and primers, it helps create a barrier that promotes long-lasting wear. This quality ensures that cosmetics adhere well to the skin, resisting smudging or fading throughout the day. A study indicated that formulations with HPMC showed superior adhesion compared to those lacking this ingredient.

In hair care, HPMC is commonly found in shampoos and conditioners, where it serves to improve viscosity and enhance the overall user experience. Its ability to provide detangling properties allows for easier application and combing through hair, which is crucial for consumer satisfaction.

Overall, the versatility of Hydroxypropyl Methylcellulose allows cosmetic formulators to create innovative and effective products that resonate well with consumers.

| Cosmetic Type | Rôle du HPMC |

|---|---|

| Skincare Products | Thickens and stabilizes formulations |

| Makeup and Foundations | Enhances wear and adhesion |

| Hair Care Products | Improves viscosity and provides detangling properties |

5. What Role Does Hydroxypropyl Methylcellulose Play in Construction?

Hydroxypropyl Methylcellulose is widely embraced in the construction industry, particularly in tile adhesives, mortars, and plasters. What’s the real story? Its exceptional properties enhance the performance of construction materials, leading to improved workability and adhesion.

In tile adhesives, HPMC contributes to optimal viscosity and provides an extended open time. This means that contractors have more flexibility when placing tiles without worrying about the adhesive drying too quickly. This feature is particularly significant in large projects where precise alignment and positioning are critical.

Moreover, in cement-based formulations, Hydroxypropyl Methylcellulose enhances water retention, allowing for better hydration of the cement. This hydration is vital for achieving the desired strength and durability of the finished product. For example, a study found that adding HPMC to mortar significantly increased its compressive strength compared to formulations without it.

Sustainability is also an essential consideration in modern construction practices. HPMC is often derived from renewable resources and is biodegradable, making it a more environmentally friendly option compared to synthetic additives. As the industry moves towards greener materials, the utilization of HPMC aligns well with these objectives.

By employing Hydroxypropyl Methylcellulose in construction applications, professionals can enhance product quality, reduce waste, and drive efficiency in building projects.

| Type d'application | Avantages du HPMC |

|---|---|

| Adhésifs pour carrelage | Improves viscosity and extends open time |

| Mortars and Plasters | Enhances water retention for hydration |

| Environmental Sustainability | Biodegradable alternative to synthetic additives |

6. Are There Benefits of Using Hydroxypropyl Methylcellulose?

The use of Hydroxypropyl Methylcellulose offers multiple advantages that make it a favored ingredient across industries. This is where it gets interesting. Its unique properties contribute to enhanced product performance, consistency, and safety, addressing many challenges faced by manufacturers.

One significant benefit is the enhanced stability that HPMC provides. Its thickening and emulsifying properties help maintain formulation integrity, preventing phase separation. This stability is particularly vital in pharmaceutical and food applications, where consistency is crucial for consumer trust.

Additionally, HPMC’s versatility as a multifunctional ingredient allows it to simplify formulations. By providing multiple roles—such as thickening, binding, and stabilizing—manufacturers can streamline their ingredient lists, potentially reducing costs and improving efficiency in production.

HPMC is also recognized for its safety and non-toxic nature. As it is derived from natural cellulose, it has a favorable safety profile that allows it to be used in various consumer products, including those for sensitive populations such as children and individuals with allergies. Regulatory organizations have classified HPMC as safe for consumption and topical application, further supporting its widespread use.

Moreover, the growing trend towards plant-based and sustainable ingredients aligns with the shift in consumer preferences. As businesses seek to develop products that resonate with eco-conscious consumers, HPMC serves as an ideal solution that meets both performance and ethical standards.

| Avantage | Impact on Formulations |

|---|---|

| Stabilité améliorée | Maintains integrity to prevent separation |

| Versatilité | Simplifies formulations, reducing costs |

| Safety Profile | Non-toxic and suitable for sensitive products |

7. What Challenges Are Associated with Hydroxypropyl Methylcellulose?

While Hydroxypropyl Methylcellulose offers numerous advantages, some challenges must be acknowledged by manufacturers. What’s the real story? Being aware of these challenges can help organizations better implement HPMC in their formulations.

One primary challenge is the variability in quality. Hydroxypropyl Methylcellulose is produced from natural cellulose materials, and differences in source materials or processing methods can lead to inconsistencies in viscosity and performance. Manufacturers must implement rigorous quality control measures to ensure that they receive consistent grades of HPMC for their applications.

Additionally, the integration of HPMC into formulations can pose challenges. It often requires specific handling techniques to ensure even dispersion and to prevent clumping, which can affect the final product’s quality. Formulators must be knowledgeable about the best practices for incorporating HPMC into various types of formulations.

Regulatory challenges associated with HPMC use also need to be addressed. Different countries have different standards for the approval and use of food-grade and pharmaceutical-grade additives, and staying compliant with these regulations can be complex. This complexity may require enhanced documentation and validation processes to meet safety and efficacy requirements.

Furthermore, competition from alternative thickening and stabilizing agents poses a market challenge. With numerous options available, manufacturers must articulate the unique advantages of HPMC to stand out among other ingredients.

By approaching these challenges with effective quality assurance, technologic know-how, and regulatory diligence, businesses can not only mitigate risks but also capitalize on the advantages Hydroxypropyl Methylcellulose offers.

| Défi | Impact on Utilization |

|---|---|

| Quality Variability | Inconsistencies can affect formulation performance |

| Integration Issues | Requires specific protocols for effective use |

| Conformité réglementaire | Complexities in meeting varied international standards |

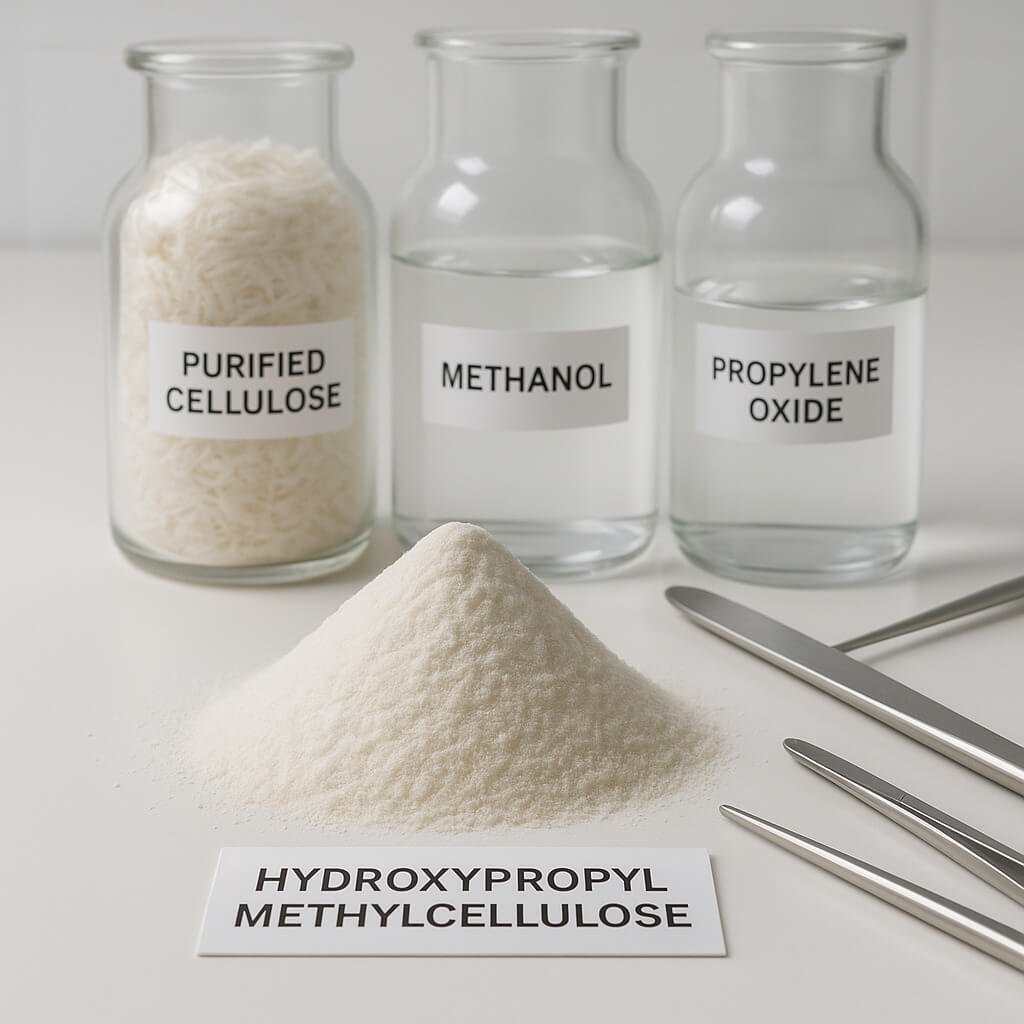

8. How is Hydroxypropyl Methylcellulose Manufactured?

Understanding the manufacturing process of Hydroxypropyl Methylcellulose provides insight into its quality and applications. Ready for the good part? The manufacturing of HPMC involves several critical steps that ensure its effectiveness as a high-performance ingredient.

The process starts with cellulose extraction from natural materials such as wood or cotton. The cellulose is then treated with an alkaline solution, which initiates the etherification reaction. During this stage, hydroxypropyl and methyl groups are introduced to the cellulose structure, transforming it into Hydroxypropyl Methylcellulose.

After etherification, the modified cellulose undergoes a dissolution process. This involves dissolving the polymer in water or suitable solvents to achieve the desired viscosity. Quality control becomes crucial at this stage, as sample testing continuously assesses the polymer’s viscosity, molecular weight, and other properties before it is dried and granulated.

Once dried, the final product is packaged for distribution. Adequate packaging is essential to maintain the quality and performance of HPMC during storage and transport, protecting it from moisture and other environmental factors that could degrade its properties.

Ongoing advancements in manufacturing technologies have propelled the efficiency of HPMC production while maintaining high quality. As the demand for green and sustainable materials increases, improved methods focus on reducing waste and enhancing the eco-friendliness of production processes.

| Manufacturing Step | Description |

|---|---|

| Cellulose Extraction | Derived from sustainable natural sources |

| Ethérification | Chemical modification to create HPMC |

| Contrôle de qualité | Continuous testing for viscosity and performance |

9. What Trends Are Affecting Hydroxypropyl Methylcellulose Usage?

The landscape of Hydroxypropyl Methylcellulose usage is continually evolving, influenced by current trends in consumer preferences and industry innovations. This is where it gets interesting. Understanding these trends is crucial for businesses seeking to harness HPMC’s potential effectively.

One significant trend is the increase in demand for Plant-Based and Natural Ingredients. As consumers become more health-conscious and environmentally aware, the preference shift toward products using sustainable and natural ingredients has grown considerably. Hydroxypropyl Methylcellulose, being derived from natural cellulose, aligns well with this trend, providing an appealing option for manufacturers.

Another trend influencing HPMC usage is the emphasis on Customization and Personalization. In sectors such as cosmetics and pharmaceuticals, consumers are increasingly seeking tailored products that meet their individual needs. HPMC’s versatility allows formulators to create customized solutions, whether they aim to enhance texture, provide controlled release, or ensure stability.

Moreover, advances in formulation technology are driving innovation in HPMC applications. For instance, the rise of biodegradable and environmentally friendly formulations has fostered the development of new products that leverage Hydroxypropyl Methylcellulose’s properties without compromising performance. This is particularly relevant in the context of sustainability in the construction industry, where eco-friendly building materials are gaining traction.

Lastly, the increasing focus on Health and Wellness has spurred interest in functional foods and pharmaceuticals. Products that promote health benefits—such as those high in fiber or with controlled-release mechanisms—are on the rise, leading to an increased demand for ingredients like HPMC that can enhance such features.

| S'orienter | Influence on HPMC Usage |

|---|---|

| Plant-Based Ingredients | Alignment with consumer preferences for sustainable products |

| Personnalisation | Enables tailored solutions for various applications |

| Innovations technologiques | Leads to environmentally friendly formulations |

10. How Can Businesses Effectively Use Hydroxypropyl Methylcellulose?

To make the most of Hydroxypropyl Methylcellulose, businesses must adopt strategic approaches to its utilization. What’s the real story? Understanding best practices can greatly enhance the effectiveness of HPMC in various applications.

First and foremost, selecting the appropriate grade of HPMC is crucial. Different grades possess varying viscosities and functionalities; thus, understanding the specifications needed for a particular application enhances product performance. Conducting trials to assess the most suitable grade for specific formulations can provide valuable insights.

Next, prehydration plays a critical role in maximizing the efficacy of Hydroxypropyl Methylcellulose. By allowing HPMC to hydrate fully prior to incorporation, formulators can achieve a more uniform dispersion and smoother texture in the final product.

Conducting thorough testing and optimization during the development stages also helps in understanding how HPMC interacts with other ingredients. Small-scale trials examining formulation stability, texture, and functionality can pave the way for successful commercialization.

Additionally, staying updated on industry trends and innovations can prove advantageous. Engaging with research and development activities will enable companies to incorporate new technologies and formulations that push the boundaries of product efficacy and consumer satisfaction.

By implementing these practices, businesses can ensure effective utilization of Hydroxypropyl Methylcellulose, driving growth and innovation across their product lines.

| Meilleures pratiques | Description |

|---|---|

| Grade Selection | Choose the right HPMC grade based on application needs |

| Prehydration | Enhances dispersion and performance |

| Ongoing R&D Engagement | Keeps abreast of innovations and trends |

Rubrique FAQ

Q1: Qu'est-ce que l'hydroxypropylméthylcellulose ?

Hydroxypropyl Methylcellulose (HPMC) is a cellulose derivative known for its thickening, gelling, and emulsifying properties, widely utilized across multiple industries such as pharmaceuticals, food, and cosmetics.

Q2: How does Hydroxypropyl Methylcellulose function in pharmaceuticals?

HPMC serves as an excipient that enhances drug formulations by controlling active ingredient release rates, improving stability and absorption, particularly in tablet and emulsion forms.

Q3: What are the food industry applications of Hydroxypropyl Methylcellulose?

HPMC is commonly used in the food industry as a thickener and stabilizer, providing texture, enhancing moisture retention, and acting as a fat replacer in lower-calorie formulations.

Q4: How is Hydroxypropyl Methylcellulose applied in cosmetics?

In the cosmetics sector, HPMC acts as a thickening agent, film-former, and emulsifier, improving the performance and sensory attributes of creams, lotions, and makeup products.

Q5: What challenges are associated with Hydroxypropyl Methylcellulose?

Challenges include variability in quality due to natural sources, integration issues during formulation, and regulatory compliance in various markets, which may complicate its implementation.