Finding reliable hydroxypropyl methylcellulose (HPMC) suppliers is a critical challenge for mortar and tile adhesive manufacturers. The right HPMC directly impacts your product quality, performance, and production costs. This article identifies the top five Chinese HPMC manufacturers specifically serving the construction adhesives industry, evaluates their strengths and weaknesses, and provides practical guidance for selecting the optimal supplier for your specific requirements. Our analysis is based on extensive industry research and feedback from leading adhesive producers who have established successful supply relationships with these manufacturers.

1. What is HPMC and Why is it Essential for Mortar and Tile Adhesives?

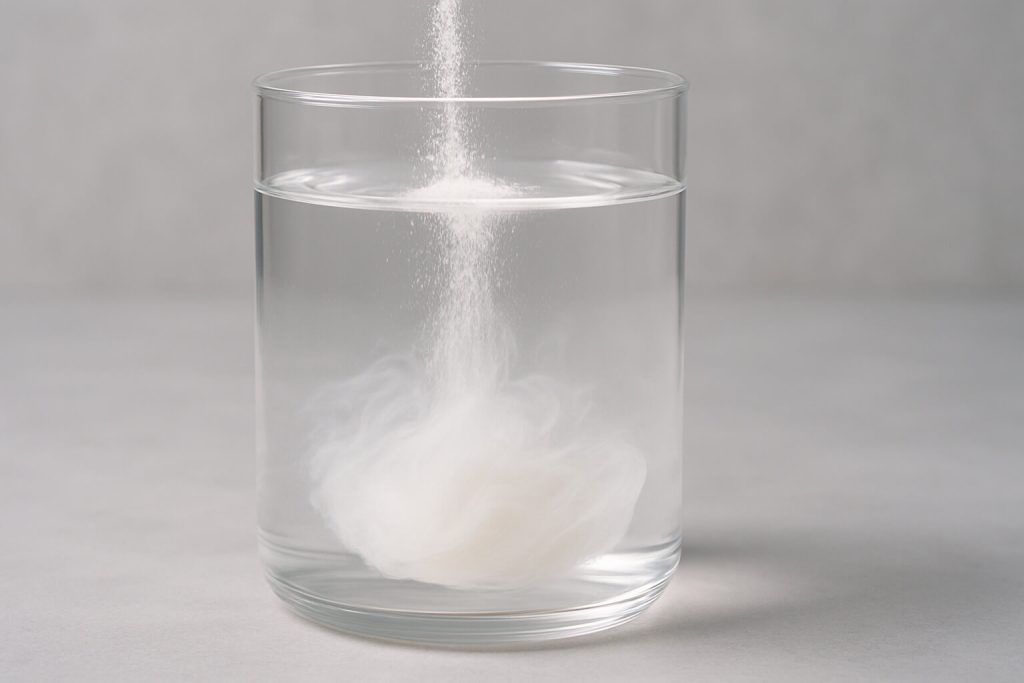

Hydroxypropyl Methylcellulose (HPMC) is a non-ionic cellulose ether derived from natural cellulose through chemical modification. This white, odorless powder dissolves in cold water to form a clear solution with remarkable functional properties. For mortar and tile adhesive manufacturers, HPMC serves as a critical multifunctional additive that significantly enhances product performance.

But here’s what makes it truly indispensable: HPMC transforms ordinary cement-based formulations into high-performance adhesives with extended open time, improved workability, and superior adhesion properties.

In mortar and tile adhesive applications, HPMC performs several essential functions:

- Water retention: HPMC prevents premature water loss during the cement hydration process, ensuring proper curing and maximum strength development.

- Workability enhancement: It improves the consistency and plasticity of fresh mortar, making application easier for end-users.

- Sag resistance: HPMC increases the viscosity of adhesives, preventing tiles from slipping during installation.

- Extended open time: It prolongs the time window during which tiles can be adjusted after adhesive application.

| Fonction HPMC | Benefit to Adhesive Performance | Impact on End-User Experience |

|---|---|---|

| Rétention d'eau | Ensures complete cement hydration | Stronger bond, reduced failure risk |

| Amélioration de la maniabilité | Smoother consistency | Easier application, less fatigue |

| Résistance à l'affaissement | Prevents tile slippage | Faster installation, fewer corrections |

| Heures d'ouverture prolongées | Longer adjustment window | Reduced waste, better alignment |

The construction industry demands specific HPMC grades with viscosities typically ranging from 15,000 to 100,000 mPa·s, with lower viscosity grades for self-leveling compounds and higher viscosity grades for wall tile adhesives where sag resistance is critical.

2. How Do You Evaluate Quality HPMC Manufacturers for Your Adhesive Production?

Selecting the right HPMC manufacturer directly impacts your adhesive product quality, consistency, and market reputation. Evaluating potential suppliers requires a systematic approach focusing on several critical parameters.

Here’s the reality you need to face: Not all HPMC is created equal, and choosing based solely on price often leads to costly formulation problems and customer complaints down the line.

When evaluating HPMC manufacturers for construction applications, prioritize these quality parameters:

- Viscosity consistency: Batch-to-batch variation should be minimal (±5% is considered excellent).

- Particle size distribution: Uniform particles ensure consistent dissolution and performance.

- Substitution degree: The methoxyl and hydroxypropyl content must meet your specific formulation requirements.

- Purity: Low gel content and minimal insoluble matter are essential for smooth application.

| Paramètre de qualité | Plage acceptable | Premium Quality Range | Impact on Adhesive Performance |

|---|---|---|---|

| Viscosity Variation | ±10% | ±5% | Consistency in application properties |

| Taille des particules | 100 mesh (90% pass) | 80 mesh (95% pass) | Dissolution speed and smoothness |

| Gel Content | <2% | <0.5% | Prevents application defects |

| Teneur en humidité | <5% | <3% | Storage stability and flow properties |

Industry certifications provide additional assurance of manufacturer quality. Look for ISO 9001:2015, ISO 14001:2015, REACH compliance for European markets, and FDA compliance for potential food-adjacent applications.

3. Which 5 Chinese Manufacturers Lead the HPMC Market for Construction Applications?

After extensive market research and feedback from industry professionals, we’ve identified the top five Chinese HPMC manufacturers specifically excelling in construction-grade products for mortar and tile adhesive applications.

What you’ll find surprising is how these manufacturers have rapidly evolved from basic commodity suppliers to specialized partners capable of meeting the most demanding technical requirements.

Manufacturer #1: Hopetop Pharmaceutical Co., Ltd.

Hopetop stands out with its massive production capacity exceeding 20,000 metric tons annually dedicated to construction-grade HPMC. Their specialized focus on high-viscosity grades makes them particularly suitable for wall tile adhesive applications.

Key strengths include advanced production technology ensuring consistent substitution degree, comprehensive quality control with automated viscosity monitoring, strong R&D collaboration with major adhesive formulators, and established export channels to over 60 countries.

Manufacturer #2: Shandong Head Co., Ltd.

Head has built its reputation on technical excellence, offering one of the most comprehensive HPMC product ranges for construction applications. Their portfolio includes specialized grades with enhanced water retention properties specifically engineered for dry-mix mortars.

Notable capabilities include customized viscosity profiles from 15,000 to 200,000 mPa·s, proprietary surface treatment technology for rapid dissolution, technical service team with construction industry expertise, and ISO 9001, ISO 14001, and REACH certifications.

Manufacturer #3: Anhui Sunhere Pharmaceutical Excipients Co., Ltd.

Sunhere distinguishes itself through exceptional quality control systems and international certifications. Their construction-grade HPMC undergoes rigorous testing, including application performance in standardized mortar formulations.

Quality assurance highlights include 100% batch testing with detailed Certificate of Analysis, advanced spectroscopy for substitution degree verification, regular third-party testing and certification, and transparent manufacturing practices with facility audit options.

Manufacturer #4: Shandong Yiteng New Material Co., Ltd.

Yiteng has established itself as an innovation leader with significant R&D investments focused on construction applications. Their customization capabilities allow adhesive manufacturers to obtain HPMC tailored to specific performance requirements.

R&D capabilities include collaborative formulation development with customers, modified HPMC grades with enhanced properties, small-batch trial production before scaling, and technical workshops and knowledge sharing.

Manufacturer #5: Henan Tiansheng Chemical Industry Co., Ltd.

Tiansheng excels in global distribution and export logistics, making them particularly valuable for international adhesive manufacturers. Their experience navigating international shipping regulations and documentation requirements streamlines the import process.

| Fabricant | Production Capacity (MT/Year) | Viscosity Range (mPa·s) | Gamme de prix (USD/MT) | Technical Support Level | Expérience d'exportation |

|---|---|---|---|---|---|

| Hopetop | 20,000+ | 60,000-100,000 | $2,800-3,200 | Excellent | Extensive (60+ countries) |

| Head | 15,000+ | 15,000-200,000 | $2,700-3,500 | Supérieur | Strong (40+ countries) |

| Sunhere | 12,000+ | 30,000-150,000 | $2,900-3,300 | Bien | Moderate (30+ countries) |

| Yiteng | 10,000+ | 25,000-100,000 | $2,600-3,100 | Excellent | Growing (20+ countries) |

| Tiansheng | 18,000+ | 40,000-120,000 | $2,500-3,000 | Bien | Strong (50+ countries) |

4. What Technical Specifications Should You Consider When Sourcing HPMC?

Understanding the technical specifications of HPMC is crucial for selecting the right grade for your specific adhesive applications. The performance of your final product depends heavily on matching these specifications to your formulation requirements.

Here’s what experienced formulators know: Small variations in HPMC specifications can have dramatic effects on application properties, working time, and final adhesion strength.

Plages de viscosité

Viscosity is perhaps the most critical parameter when selecting HPMC for mortar and tile adhesives. It directly affects workability, water retention, and sag resistance.

For tile adhesives, the optimal viscosity ranges are:

- Floor tile adhesives: 30,000-50,000 mPa·s

- Wall tile adhesives: 60,000-100,000 mPa·s

- Self-leveling compounds: 15,000-25,000 mPa·s

Methoxyl and Hydroxypropyl Content

The substitution degree (SD) of HPMC refers to the percentage of hydroxyl groups in the cellulose molecule that have been substituted with methoxyl and hydroxypropyl groups. This chemical characteristic significantly influences solubility, thermal gelation, and water retention properties.

| Substitution Parameter | Typical Range for Construction | Effect on Performance |

|---|---|---|

| Teneur en méthoxyle | 19-24% | Higher values improve water retention |

| Teneur en hydroxypropyle | 7-12% | Higher values enhance surface activity |

| Molar Substitution | 0.1-0.3 | Affects dissolution temperature |

Construction-grade HPMC typically requires a methoxyl content of 19-24% and hydroxypropyl content of 7-12%. Higher methoxyl content generally improves water retention, while higher hydroxypropyl content enhances surface activity and adhesion.

Capacité de rétention d'eau

Water retention is a defining functional property of HPMC in cementitious systems. It prevents premature water loss, ensuring proper cement hydration and maximum strength development.

| Water Retention Value | Adéquation de l'application | Working Time |

|---|---|---|

| >95% | Premium tile adhesives | Extended (>30 min) |

| 90-95% | Colles à carrelage standard | Standard (20-30 min) |

| 85-90% | Economy formulations | Shorter (15-20 min) |

| <85% | Non recommandé | Insufficient |

5. How Does HPMC from Chinese Manufacturers Compare to International Alternatives?

When evaluating Chinese HPMC against products from established Western manufacturers like Dow, Ashland, or SE Tylose, several key comparison factors emerge. Understanding these differences helps adhesive manufacturers make informed sourcing decisions.

What might surprise you is how rapidly Chinese manufacturers have closed the quality gap while maintaining significant price advantages.

Price-Performance Ratio

The most compelling advantage of Chinese HPMC is its price-performance ratio. Chinese products typically cost 15-30% less than Western equivalents with comparable technical specifications.

| Origin | Average Price Range (USD/MT) | Relative Performance Rating | Price-Performance Ratio |

|---|---|---|---|

| Chinese Premium | $2,800-3,300 | 85-95% | Excellent |

| Chinese Standard | $2,400-2,800 | 75-85% | Very Good |

| Western Premium | $3,800-4,500 | 95-100% | Bien |

| Western Standard | $3,200-3,800 | 85-95% | Modéré |

This price advantage allows adhesive manufacturers to either improve margins or offer more competitive pricing to their customers.

Cohérence de la qualité

Historically, batch-to-batch consistency was a concern with Chinese manufacturers. However, leading Chinese producers have made significant investments in quality control systems and automated production technology.

Top-tier Chinese manufacturers now achieve consistency levels approaching Western standards:

- Viscosity variation: ±7-10% (compared to ±5-7% for Western products)

- Substitution degree consistency: ±3-5% (compared to ±2-3% for Western products)

- Particle size distribution: Increasingly uniform with advanced milling equipment

Technical Support and Service

Western manufacturers traditionally excelled in technical support, but leading Chinese producers have invested heavily in this area:

- Application laboratories with construction industry focus

- Technical teams with international experience

- English-speaking technical support staff

- Regular technical seminars and training

- Collaborative problem-solving approaches

6. What Are the Best Practices for Importing HPMC from China?

Importing HPMC from China requires navigating several logistical, regulatory, and quality assurance challenges. Following established best practices can help ensure a smooth procurement process and consistent product quality.

But here’s what experienced importers understand: Building a successful import program requires more than just finding the right supplier—it demands systematic processes for qualification, verification, and relationship management.

Navigating Import Regulations

HPMC is classified under HS Code 3912.39, which covers “Cellulose and its chemical derivatives, not elsewhere specified, in primary forms.” Import requirements vary by country but typically include:

- Import license or permit for chemical substances

- Safety Data Sheet (SDS) in the local language

- Certificate of Analysis (COA) for each batch

- Certificate of Origin to determine applicable tariffs

- Customs declaration with accurate product description

| Documentation Requirement | But | Responsible Party |

|---|---|---|

| Commercial Invoice | Customs valuation | Supplier |

| Packing List | Cargo identification | Supplier |

| Bill of Lading | Transport contract | Freight forwarder |

| Certificate of Analysis | Quality verification | Supplier |

| Certificat d'origine | Tariff determination | Supplier |

Quality Control Procedures

Implementing robust quality control procedures is essential when importing HPMC:

- Pre-shipment inspection: Consider third-party inspection before shipment

- Sample testing: Request pre-shipment samples for testing

- Certificate of Analysis verification: Compare against your specifications

- Arrival inspection: Visual inspection of packaging and product condition

- Performance testing: Verify key parameters in your application

7. How Will Future Trends Impact HPMC Sourcing for Adhesive Manufacturers?

The HPMC market is evolving rapidly, with several emerging trends poised to impact sourcing strategies for adhesive manufacturers. Understanding these developments can help you position your supply chain advantageously for the future.

What forward-thinking purchasing managers recognize is that proactive adaptation to these trends can create competitive advantages through improved product performance, cost management, and supply security.

Emerging Eco-Friendly HPMC Formulations

Sustainability has become a major focus in construction materials, driving development of eco-friendly HPMC variants:

- Bio-based cellulose sources: Manufacturers are exploring sustainable forestry and agricultural waste as cellulose sources

- Reduced environmental impact production: Lower energy consumption and water usage in manufacturing

- Biodegradable additives: Complementary ingredients that maintain performance while improving environmental profile

- Carbon footprint certification: Documentation of environmental impact throughout the production cycle

Innovations technologiques dans la production de HPMC

Manufacturing technology advances are improving HPMC performance and consistency:

- Precision control of substitution: More precise control of methoxyl and hydroxypropyl content

- Advanced particle engineering: Optimized dissolution profiles through particle size and shape control

- Hybrid products: HPMC combined with complementary polymers for enhanced performance

- Application-specific modifications: Customized products for specific end-uses

These innovations are enabling new performance levels in adhesive applications, including extended open time without compromised final strength, improved sag resistance with better workability, enhanced water retention in challenging conditions, and faster strength development.

Conclusion

Selecting the right HPMC manufacturer is a critical decision that directly impacts your adhesive product quality, consistency, and cost structure. The top five Chinese manufacturers highlighted in this article—Hopetop, Head, Sunhere, Yiteng, and Tiansheng—have demonstrated their capability to meet international quality standards while offering significant cost advantages compared to Western alternatives.

When evaluating these manufacturers, consider your specific technical requirements, quality expectations, and supply chain priorities. The optimal choice depends on your particular application needs, production volume, and market positioning. Many adhesive manufacturers find that establishing relationships with multiple suppliers provides the best balance of cost, quality, and supply security.

As the HPMC market continues to evolve, staying informed about emerging trends in eco-friendly formulations, production technology, and regulatory requirements will help you maintain a competitive edge. Chinese manufacturers are increasingly positioning themselves as innovation partners rather than merely material suppliers, offering collaborative development opportunities alongside competitive pricing.

FAQ

Q1: What is the typical price range for construction-grade HPMC from Chinese manufacturers?

Construction-grade HPMC from Chinese manufacturers typically ranges from $2,400 to $3,300 per metric ton, depending on viscosity, quality tier, and order volume. Lower viscosity grades (15,000-30,000 mPa·s) generally fall in the $2,400-$2,800 range, while higher viscosity grades (60,000-100,000 mPa·s) command $2,800-$3,300. Premium grades with enhanced performance characteristics or specialized modifications may reach $3,500. Most manufacturers offer volume discounts starting at 5-10 metric tons, with potential savings of 5-10% for larger orders.

Q2: How does HPMC viscosity affect tile adhesive performance?

HPMC viscosity directly influences several critical tile adhesive performance parameters. Higher viscosity grades (60,000-100,000 mPa·s) provide superior sag resistance, making them ideal for wall applications where preventing tile slippage is essential. They also offer enhanced water retention, extending open time and adjustment windows. Medium viscosity grades (30,000-50,000 mPa·s) balance workability with adequate water retention, making them suitable for floor tile applications. Lower viscosity grades (15,000-30,000 mPa·s) improve flow properties for self-leveling compounds but provide less sag resistance.

Q3: Can Chinese HPMC manufacturers provide custom formulations for specific adhesive requirements?

Yes, leading Chinese HPMC manufacturers have developed significant customization capabilities. Manufacturers like Yiteng and Head offer collaborative development programs for custom formulations tailored to specific performance requirements. These customization options include modified dissolution profiles, optimized water retention properties, adjusted thermal gelation temperatures, and specialized particle size distributions. Minimum order quantities for custom formulations typically range from 3-5 metric tons, with development timeframes of 4-8 weeks depending on complexity.

Q4: What are the most common quality issues with HPMC from less reputable manufacturers?

The most common quality issues with HPMC from less reputable manufacturers include inconsistent viscosity between batches (variations exceeding ±15%), poor dissolution characteristics (clumping or slow hydration), excessive insoluble particles causing application defects, inadequate water retention leading to premature drying, and imprecise substitution degree affecting performance stability. These issues typically manifest as inconsistent working time, reduced adhesion strength, application difficulties, and customer complaints.

Q5: How should HPMC be stored to maintain its properties for adhesive production?

HPMC should be stored in cool, dry conditions with temperatures between 10-30°C (50-86°F) and relative humidity below 65% to maintain optimal properties. The material should remain in its original sealed packaging until use to prevent moisture absorption, which can cause clumping and affect dissolution properties. Pallets should be elevated from the floor and away from walls to allow air circulation and prevent moisture transfer. Under proper storage conditions, HPMC typically maintains its specified properties for 24-36 months from production date.