Hydroxypropyl Methylcellulose (HPMC) K15 is a versatile compound used across various industrial sectors. Known for its unique properties, it plays a significant role in applications ranging from construction to pharmaceuticals. In this article, we will explore what HPMC K15 is, its benefits, its uses across different industries, and why it is crucial for certain manufacturing processes. We’ll also dive into how it compares to other grades of HPMC and the environmental considerations surrounding its use.

1. What is HPMC K15 and Why is it Important for Industries?

HPMC K15 is a specific grade of Hydroxypropyl Methylcellulose, a cellulose ether used in various applications due to its unique properties, including its ability to control viscosity, enhance stability, and act as a binder in multiple industries. Ecco il punto cruciale: While HPMC K15 is widely used, its exact benefits often depend on the specific industry and application.

In the construction industry, HPMC K15 is added to mortar mixes and tile adhesives, providing increased workability and water retention. Pronti per la parte bella? In the pharmaceutical industry, HPMC K15 is crucial in the formulation of controlled-release drugs, offering a consistent dissolution profile. In food and cosmetics, its role as a stabilizer and thickener is equally vital.

But what sets HPMC K15 apart from other grades? One of its defining features is its medium viscosity, which allows it to function well in a broad range of applications, from improving texture in food products to controlling the release rate in drug formulations. Additionally, HPMC K15 can be modified to suit specific customer requirements, making it a flexible choice across industries.

Table: Key Properties of HPMC K15

| Proprietà | Descrizione | Applicazioni |

|---|---|---|

| Viscosità | Medium viscosity grade | Construction, Pharmaceuticals, Food, Cosmetics |

| Solubilità | Solubile in acqua | Pharmaceutical formulations, Food stabilizer |

| Binder Capacity | Strong binder, enhances adhesion | Mortar, Tile adhesives, Cosmetics |

| Normativa | Complies with FDA, USP, and EP standards | Food and pharmaceutical manufacturing |

2. How Does HPMC K15 Differ from Other Grades of HPMC?

When it comes to Hydroxypropyl Methylcellulose (HPMC), there are several grades available, each with its unique characteristics tailored to specific applications. Qual è la vera storia? HPMC K15 stands out due to its medium viscosity, making it ideal for a variety of industrial uses.

In comparison to other grades, such as HPMC K4M (which has low viscosity) and HPMC K100 (which has high viscosity), HPMC K15 strikes a balance. This balance makes it particularly useful in applications where medium viscosity is needed for proper flow and consistency. For instance, in the pharmaceutical sector, HPMC K15 is preferred for controlled-release formulations, whereas other grades may not offer the same level of stability.

Another significant difference is its solubility and its ability to form gel-like substances when mixed with water. The ability to tailor the viscosity and solubility of HPMC K15 allows it to meet the varying demands of customers in industries like construction, food, and pharmaceuticals. This is where it gets interesting… You’ll find that HPMC K15’s flexibility in formulation makes it a go-to solution for manufacturers needing reliable, cost-effective performance across different sectors.

Table: Comparison of HPMC Grades

| Grado | Viscosità | Solubilità | Applicazioni comuni |

|---|---|---|---|

| K4M | Basso | Solubile in acqua | Pharmaceuticals, Food |

| K15 | Medio | Solubile in acqua | Construction, Cosmetics |

| K100 | Alto | Solubile in acqua | Thickening agents, Food |

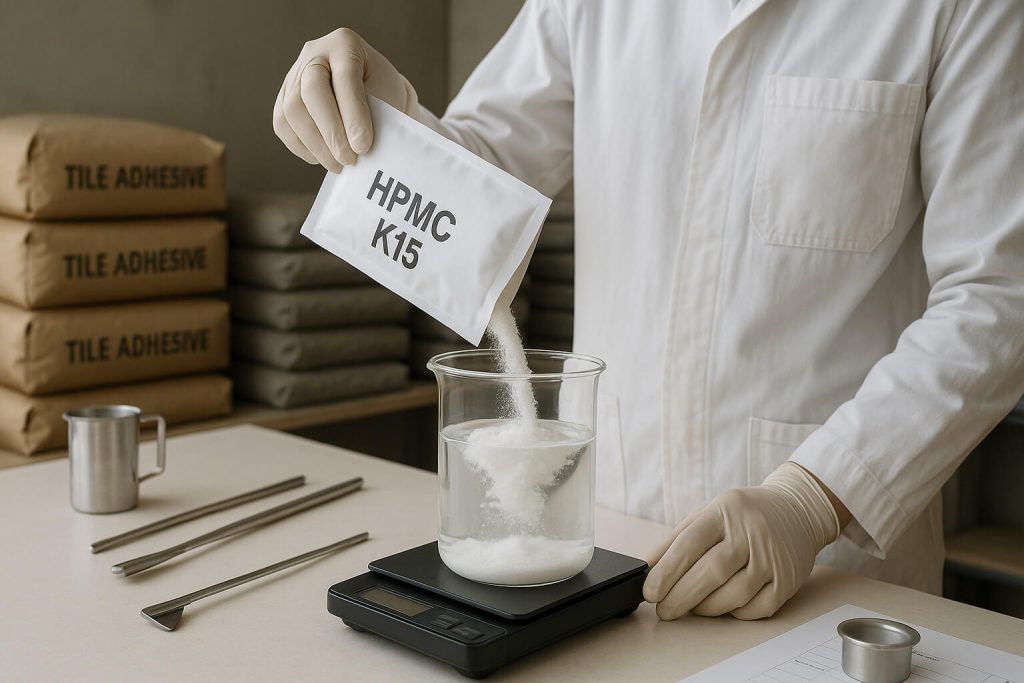

3. What Are the Main Uses of HPMC K15 in the Construction Industry?

In the construction industry, HPMC K15 is commonly used in dry mortar mixes, tile adhesives, and cement-based products. What’s the deal with this? It plays a crucial role in improving the workability, viscosity, and overall performance of construction materials.

HPMC K15 is added to cement mixes to enhance their water retention properties. This means that the mortar or tile adhesive will remain workable for a longer period, which is critical for large-scale construction projects. Ma ecco il punto: The longer working time allows workers to apply materials more efficiently and effectively, reducing waste and improving the quality of the final product.

Additionally, HPMC K15 improves the bond strength of tile adhesives, making it a popular choice in flooring and tiling applications. This increase in bond strength ensures that tiles stay firmly in place over time, reducing the likelihood of tile loosening or detachment due to changes in environmental conditions.

Table: HPMC K15 Uses in Construction

| Applicazione | Beneficio | Impatto |

|---|---|---|

| Adesivi per piastrelle | Increases bond strength | Ensures long-lasting tile installation |

| Dry Mortar | Migliora la ritenzione idrica | Reduces material wastage, improves workability |

| Cement-based Products | Improves consistency and performance | Better adhesion and reduced application time |

4. How Is HPMC K15 Used in the Pharmaceutical Industry?

In pharmaceuticals, HPMC K15 is mainly used in controlled-release drug formulations, where it acts as a binder and stabilizer. What’s the real story here? HPMC K15 controls the release of active pharmaceutical ingredients (APIs), ensuring they are delivered at a steady rate over time.

This controlled-release capability is especially important for drugs that need to be absorbed gradually by the body, improving efficacy and reducing side effects. Ecco il punto cruciale: In tablet production, HPMC K15 is used not only to bind the ingredients but also to help the tablet maintain its shape and stability, even when exposed to moisture or humidity.

Moreover, HPMC K15 is favored in formulations for sustained or extended-release products. This ensures that patients benefit from a constant, controlled dose of medication throughout the day, enhancing the therapeutic outcome.

Table: HPMC K15 in Pharmaceuticals

| Applicazione | Beneficio | Impatto |

|---|---|---|

| Controlled Release Drugs | Slow, sustained API release | Enhances therapeutic effect |

| Formulazioni in compresse | Acts as a binder and stabilizer | Maintains tablet integrity under various conditions |

5. How Does HPMC K15 Contribute to Food Manufacturing?

HPMC K15 is used extensively in the food industry, particularly as a stabilizer, emulsifier, and thickener. Pronti per la parte bella? It helps improve the texture, viscosity, and consistency of various food products, from sauces and soups to dairy products and beverages.

One of the primary benefits of using HPMC K15 in food manufacturing is its ability to maintain the desired texture and viscosity over time. For example, in sauces, HPMC K15 prevents separation, ensuring that the product remains uniform and stable. What’s the catch? HPMC K15 also increases the shelf life of food products, making it an essential ingredient for manufacturers looking to extend product longevity while maintaining quality.

Additionally, HPMC K15 is considered safe for use in food products, meeting international standards such as those set by the FDA and European regulators. Its status as a non-toxic, biodegradable additive further increases its appeal in the food manufacturing sector.

Table: HPMC K15 in Food Products

| Applicazione | Funzione | Beneficio |

|---|---|---|

| Sauces and Soups | Thickening and stabilizing | Improves texture and prevents separation |

| Prodotti lattiero-caseari | Stabilizing agent | Enhances consistency and extends shelf life |

| Beverages | Emulsifying agent | Garantisce uniformità e stabilità |

6. What Are the Key Benefits of Using HPMC K15 in Cosmetics?

In the cosmetics industry, HPMC K15 is widely used for its ability to enhance texture, stability, and skin compatibility in products like lotions, creams, and gels. What’s the big deal? Its unique properties make it ideal for creating smooth, uniform formulations that are easy to apply and remain stable over time.

One of the primary benefits of HPMC K15 in cosmetics is its ability to form clear, smooth gels and emulsions. Ma ecco il punto: The compound’s water-binding ability also helps maintain hydration and moisture retention in skin care products, making it particularly useful in moisturizers and anti-aging creams.

Additionally, HPMC K15 can improve the spreadability of cosmetic products, ensuring that the product goes on smoothly without leaving a sticky or greasy residue. Qui è dove la cosa diventa interessante: For consumers, this means a more pleasant, non-greasy application experience.

Table: HPMC K15 in Cosmetics

| Applicazione | Funzione | Beneficio |

|---|---|---|

| Lotions and Creams | Thickening, stabilizing | Improved texture, better consistency |

| Anti-aging Products | Hydration and moisture retention | Maintains skin hydration, smooth application |

| Gels | Gelling agent, stabilizer | Clear gels with enhanced stability |

7. How Does HPMC K15 Affect the Production of Oilfield Chemicals?

In the oil and gas industry, HPMC K15 plays a critical role in the production of drilling fluids, oil recovery agents, and other chemical formulations. Pronti per la parte bella? HPMC K15 helps control viscosity and ensures that drilling fluids remain stable even under extreme conditions.

When used in drilling fluids, HPMC K15 functions as a suspending agent, keeping solid particles in suspension and preventing them from settling. What’s the deal? This improves the efficiency of drilling operations and reduces the need for frequent maintenance or re-mixing of fluids.

HPMC K15 also helps in enhanced oil recovery (EOR) processes, where it controls the viscosity of water or polymer solutions used to push oil to the surface. This ability to adjust viscosity makes HPMC K15 a valuable asset in the oil and gas industry, enhancing overall production efficiency.

Table: HPMC K15 in Oilfield Chemicals

| Applicazione | Funzione | Impatto |

|---|---|---|

| Drilling Fluids | Suspends particles, controls viscosity | Improves drilling efficiency |

| Enhanced Oil Recovery | Viscosity control for water/polymer solutions | Increases oil extraction efficiency |

8. What Are the Environmental and Health Considerations for HPMC K15?

HPMC K15 is considered safe for use in a wide range of applications, but like all chemicals, it must be handled with care. What’s the real story here? Despite its broad usage, it’s important to consider the environmental and health impacts of HPMC K15.

HPMC K15 is biodegradable, which means it breaks down naturally over time without leaving harmful residues in the environment. Ma ecco il punto: Its production also follows strict environmental regulations, ensuring that its use in various industries complies with both local and global standards.

In terms of health, HPMC K15 is classified as non-toxic and poses minimal risk when used in food, pharmaceuticals, and cosmetics. It is generally regarded as safe, with minimal irritation to the skin or respiratory system, making it suitable for various industrial applications.

Table: Environmental and Health Considerations for HPMC K15

| Fattore | Descrizione | Impatto |

|---|---|---|

| Biodegradabilità | Si decompone naturalmente nell'ambiente | Riduce l'impatto ambientale a lungo termine |

| Health Safety | Non-toxic, minimal irritation | Safe for use in food, pharmaceuticals, and cosmetics |

9. How Do You Select the Right Grade of HPMC for Specific Applications?

When selecting an HPMC grade, it’s crucial to consider the specific needs of the application. Qual è la vera storia? Different grades of HPMC offer varying properties like viscosity, solubility, and gel strength, so understanding these factors is key to making the right choice.

HPMC K15 is a medium-viscosity grade, making it suitable for a wide range of applications. Ecco il punto cruciale: If you need higher viscosity for thickening or suspension, a grade like HPMC K100 may be more appropriate. Conversely, for lower viscosity applications, HPMC K4M could be a better fit.

Selecting the right grade also depends on factors like solubility, water retention, and specific product requirements. Whether for pharmaceutical tablets, construction adhesives, or cosmetics, HPMC grades are carefully chosen based on the application’s desired performance.

Table: Selection Criteria for HPMC Grades

| Fattore | Motore HPMC K4M | HPMC K15 | HPMC K100 |

|---|---|---|---|

| Viscosità | Basso | Medio | Alto |

| Applicazione | Pharmaceuticals, Food | Construction, Cosmetics | Heavy-duty applications |

| Solubilità | Solubile in acqua | Solubile in acqua | Solubile in acqua |

10. What Are the Future Trends and Innovations in HPMC K15 Production and Use?

The future of HPMC K15 looks promising, as industries continue to innovate and adapt to new challenges. What’s the deal with this? New technologies in HPMC production are expected to improve efficiency and reduce environmental impact, paving the way for even more widespread use.

As sustainability becomes a higher priority, the production of HPMC K15 may shift towards greener practices, focusing on minimizing waste and energy consumption. Pronti per la parte bella? Additionally, we can expect to see HPMC K15’s applications expand into new sectors, including renewable energy and advanced manufacturing, as industries seek new materials for specialized needs.

Table: Future Trends in HPMC K15 Production

| Tendenza | Descrizione | Impatto potenziale |

|---|---|---|

| Produzione sostenibile | Green production practices | Reduced environmental footprint |

| Expanding Applications | New uses in renewable energy, advanced manufacturing | Opens up new markets and industries |

Conclusione

HPMC K15 is an essential compound across multiple industries, from construction to pharmaceuticals, food, and cosmetics. Ecco il punto cruciale: Its versatility and ability to improve performance in various applications make it a valuable asset for manufacturers. Whether you’re looking to enhance adhesion in construction or control drug release in pharmaceuticals, HPMC K15 delivers reliable, effective results. As industries evolve, so too will the applications of HPMC K15, ensuring its continued importance in the years to come.

Domande frequenti

Domanda 1: What is HPMC K15?

HPMC K15 is a grade of Hydroxypropyl Methylcellulose, a cellulose ether used for its unique properties like viscosity control and water retention in various industries.

D2: How does HPMC K15 work in construction materials?

HPMC K15 is used in dry mortars and tile adhesives to enhance workability, water retention, and bonding strength, making it ideal for construction applications.

D3: What are the advantages of using HPMC K15 in pharmaceuticals?

HPMC K15 is used in controlled-release drug formulations, ensuring consistent API delivery and improving the stability and efficacy of medications.

D4: Can HPMC K15 be used in food products?

Yes, HPMC K15 is a safe and effective stabilizer, thickener, and emulsifier used in food products to improve texture, viscosity, and shelf life.

D5: Is HPMC K15 environmentally friendly?

HPMC K15 is biodegradable, non-toxic, and produced in compliance with environmental regulations, making it safe for both consumers and the environment.