Hydroxypropyl methylcellulose (HPMC) dissolution presents a significant challenge for many manufacturing processes. This versatile polymer, while invaluable across industries from pharmaceuticals to construction, requires specific techniques to achieve proper dissolution. Improper dissolution can lead to product defects, inconsistent performance, and manufacturing delays. This article provides comprehensive guidance on optimal dissolution methods, addressing the common pain points experienced by processing engineers and production managers. Our recommendations are based on extensive industry experience and technical expertise, ensuring you can implement effective dissolution protocols regardless of your specific application requirements.

1. What is Hydroxypropyl Methylcellulose and Why is Dissolution Important?

Hydroxypropyl methylcellulose (HPMC) is a semi-synthetic, inert polymer derived from cellulose. It consists of cellulose ethers with methoxyl and hydroxypropyl groups attached to the anhydroglucose units of the cellulose backbone. This unique chemical structure gives HPMC its valuable properties, including solubility in water, film-forming capabilities, and viscosity control.

Ma ecco il punto – despite its water-soluble nature, HPMC doesn’t dissolve as easily as many other polymers. Its dissolution behavior is complex and depends on several factors including temperature, concentration, and molecular weight.

The importance of proper dissolution cannot be overstated. When HPMC dissolves completely and uniformly, it delivers consistent performance in the final product. Incomplete dissolution, on the other hand, can lead to:

- Lumps or “fish eyes” in solutions

- Inconsistent viscosity profiles

- Poor film formation

- Reduced binding efficiency

- Compromised product stability

- Quality control failures

Industries rely on HPMC for diverse applications, from pharmaceutical tablet coatings to construction materials. In pharmaceuticals, HPMC serves as a controlled-release matrix, coating agent, and binder. The construction industry uses it as a cement modifier, improving water retention and workability. Food manufacturers incorporate it as a thickener and stabilizer, while personal care products utilize its film-forming properties.

| Industria | Applicazioni primarie HPMC | Critical Dissolution Requirements |

|---|---|---|

| Prodotti farmaceutici | Tablet coatings, controlled release matrices | Complete dissolution, sterility, consistent viscosity |

| Costruzione | Cement additives, renders, mortars | Lump-free incorporation, rapid dispersion |

| Cibo | Thickeners, stabilizers | Food-grade processing, transparent solutions |

| Cura della persona | Gels, lotions, creams | Smooth texture, complete hydration |

| Technical Coatings | Adhesives, paints | Uniform film formation, consistent rheology |

2. What Are the Key Factors Affecting HPMC Dissolution?

Understanding the factors that influence HPMC dissolution is crucial for optimizing your process. These variables determine not only dissolution speed but also the quality of the final solution.

Temperature plays a pivotal role in HPMC dissolution behavior. Unlike many polymers, HPMC exhibits inverse solubility with respect to temperature – it dissolves more readily in cold water than hot. This counterintuitive property stems from its unique molecular structure.

Potresti rimanere sorpreso nell'apprendere that HPMC undergoes a gelation process in hot water before dissolving. When initially exposed to hot water (above 85°C), HPMC forms a hydrated layer on its surface that prevents water penetration to the core, resulting in lumps. In cold water, this gelation doesn’t occur, allowing for more uniform hydration.

Particle size significantly impacts dissolution rate. Finer HPMC particles provide greater surface area for water contact, accelerating dissolution. However, extremely fine particles may agglomerate more easily, potentially forming lumps if not properly dispersed.

| Grado HPMC | Typical Particle Size | Dissolution Characteristics | Best Dissolution Method |

|---|---|---|---|

| Bene | <75 μm | Rapid dissolution, high risk of lumping | Cold dispersion with high shear |

| Medio | 75-125 μm | Moderate dissolution rate, balanced properties | Cold dispersion or hot/cold method |

| Grossolano | >125 μm | Slower dissolution, lower risk of lumping | Hot/cold method with extended hydration time |

Water quality parameters, including mineral content and pH, also affect dissolution. Hard water containing high levels of calcium and magnesium can interfere with HPMC hydration. Similarly, extreme pH conditions may alter dissolution kinetics and the properties of the resulting solution.

Agitation method and intensity directly impact dissolution efficiency. Insufficient agitation leads to localized concentration gradients and potential lump formation. Conversely, excessive shear can damage the polymer structure in some high-molecular-weight grades. The optimal agitation approach depends on:

- Concentrazione di HPMC

- Molecular weight and substitution type

- Batch size

- Available equipment

- Required dissolution time

3. What’s the Step-by-Step Process for Dissolving HPMC?

Achieving optimal HPMC dissolution requires following specific procedures tailored to your application requirements. Three primary methods exist, each with distinct advantages for particular situations.

Cold Water Dispersion Technique

The cold water dispersion method is widely used for its simplicity and effectiveness in preventing lump formation.

- Prepare cold water (10-15°C) in your mixing vessel

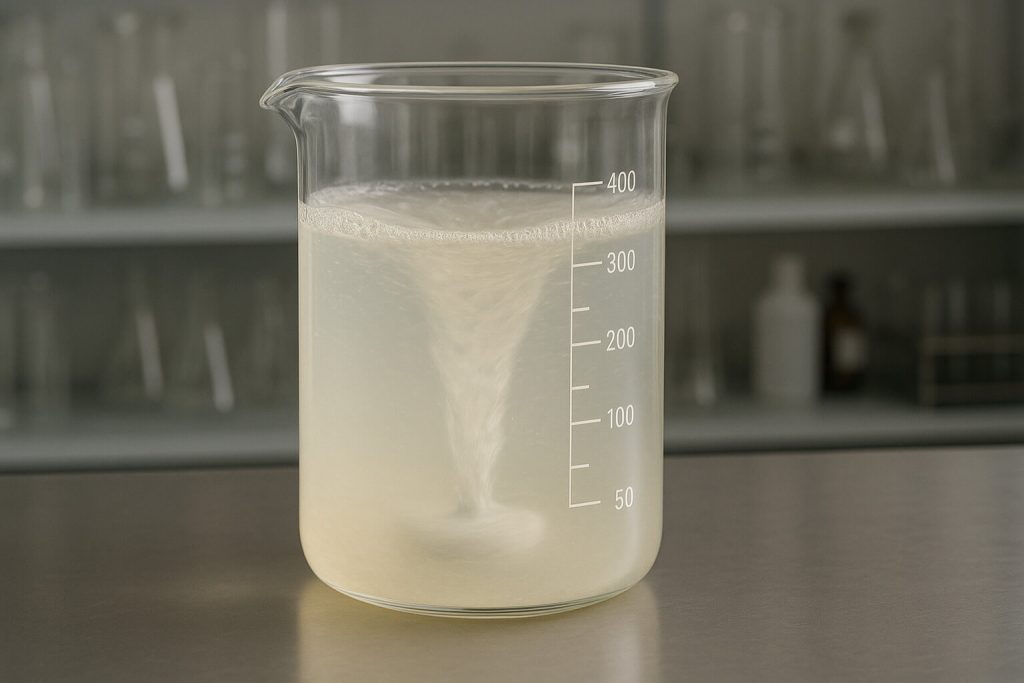

- Begin moderate agitation to create a vortex

- Slowly add HPMC powder to the vortex periphery

- Maintain agitation until complete dissolution (typically 30-60 minutes)

- Allow solution to stand for deaeration if needed

Here’s the critical part – the addition rate must be carefully controlled. Adding HPMC too quickly leads to agglomeration and lumps. For higher concentrations (>2%), consider using a powder disperser or high-shear mixer.

Hot Water Dissolution Method

This approach leverages HPMC’s thermal gelation properties:

- Heat water to 80-90°C in the mixing vessel

- Add HPMC powder with vigorous agitation

- Continue mixing until particles are thoroughly wetted

- Cool the mixture to below 20°C while maintaining agitation

- Continue mixing until complete dissolution

This method works well for higher concentrations but requires temperature control equipment and longer processing times.

Combined Hot/Cold Process

The combined approach offers advantages for certain applications:

- Heat approximately 1/3 of the required water to 80-90°C

- Add HPMC powder to the hot water with vigorous agitation

- Add the remaining 2/3 of water as cold water or ice

- Continue mixing until complete dissolution

| Metodo di dissoluzione | Vantaggi | Svantaggi | Best For |

|---|---|---|---|

| Cold Water Dispersion | Simple setup, fewer temperature changes | Longer dissolution time, risk of lumping at high concentrations | Low to medium concentrations, limited equipment |

| Hot Water Method | Effective for high concentrations, reduced lumping | Requires heating/cooling capability, longer process time | High concentrations, when equipment permits temperature control |

| Combined Hot/Cold | Faster than cold method, less equipment than hot method | Requires precise temperature management | Medium to high concentrations, moderate batch sizes |

Equipment selection significantly impacts dissolution efficiency. Laboratory-scale preparations typically use magnetic stirrers or overhead mixers. Production-scale processes may employ:

- High-shear mixers for rapid dispersion

- Powder induction systems for lump-free incorporation

- Inline mixing systems for continuous processing

Monitoring dissolution completion requires both visual inspection and viscosity testing. A properly dissolved HPMC solution should be clear or slightly translucent without visible particles or gel lumps.

4. How Do Different Industries Optimize HPMC Dissolution?

Different industries have developed specialized approaches to HPMC dissolution based on their unique requirements and constraints.

The pharmaceutical industry prioritizes purity, consistency, and documentation. Pharmaceutical manufacturers typically employ validated dissolution procedures with precise temperature control and filtered water systems. For tablet coating applications, HPMC is often dissolved using specialized equipment that ensures uniform dispersion and complete hydration.

What makes pharmaceutical applications unique is the need for sterile processing in many cases. This requires additional considerations such as sanitized equipment and controlled environments. Pharmaceutical grades of HPMC also undergo more rigorous testing for dissolution characteristics.

Construction material manufacturers face different challenges, primarily related to scale and integration with dry ingredients. In this sector, HPMC is often pre-blended with dry components before water addition. Alternatively, it may be pre-dissolved as a concentrated solution and added to the mix.

| Industria | Typical Dissolution Method | Focus sull'ottimizzazione chiave | Quality Control Parameters |

|---|---|---|---|

| Farmaceutico | Cold water with controlled agitation | Sterility, documentation, validation | Viscosità, limpidezza, limiti microbici |

| Costruzione | Pre-blending or concentrated solutions | Scale efficiency, compatibility with other additives | Water retention, consistency, workability |

| Cibo | Cold process with food-grade equipment | Clean processing, taste neutrality | Clarity, mouthfeel, stability |

| Cura della persona | Cold process with homogenization | Smooth texture, compatibility with actives | Appearance, feel, stability |

| Technical Coatings | Method varies by application | Rheology control, film properties | Viscosity profile, film characteristics |

Food industry applications require food-grade processing equipment and often involve incorporation with other ingredients. Manufacturers typically use cold water dissolution with specialized dispersers designed to prevent lumping while maintaining sanitary conditions.

Personal care product manufacturers focus on achieving smooth textures and compatibility with active ingredients. They frequently employ high-shear mixing systems and may combine HPMC with other polymers or surfactants during the dissolution process.

Technical coatings and adhesives producers optimize dissolution based on the specific rheological properties required. They may use specialized dissolution equipment that provides precise control over shear rates and temperature profiles.

5. What Common Problems Occur During HPMC Dissolution and How to Solve Them?

Despite following recommended procedures, challenges can arise during HPMC dissolution. Recognizing and addressing these issues promptly helps maintain production efficiency and product quality.

Lump formation represents the most common dissolution problem. These agglomerates, often called “fish eyes,” consist of hydrated outer layers surrounding dry powder cores. Once formed, they dissolve extremely slowly.

La realtà è that prevention is far easier than remediation. Effective prevention strategies include:

- Using a vortex addition technique

- Implementing powder dispersers or eductor systems

- Pre-blending HPMC with compatible dry ingredients

- Employing the hot/cold method for high concentrations

- Adding HPMC to the liquid phase before other ingredients

Incomplete dissolution manifests as hazy solutions, visible particles, or inconsistent viscosity. This issue typically results from insufficient mixing time, improper temperature management, or incompatible ingredients.

| Problema | Cause | Solutions | Prevention Strategies |

|---|---|---|---|

| Formazione di grumi | Too rapid addition, insufficient agitation, improper temperature | High-shear mixing, extended hydration time, straining | Controlled addition rate, vortex technique, proper equipment |

| Dissoluzione incompleta | Insufficient time, inadequate agitation, incompatible ingredients | Extended mixing, temperature adjustment, sequential addition | Process validation, quality control checks, optimized protocols |

| Viscosity Inconsistencies | Variable hydration, temperature fluctuations, pH variations | Standardized conditions, controlled environment, pH adjustment | Process monitoring, equipment calibration, water quality control |

| Excessive Dissolution Time | Particle size issues, low temperature, high concentration | Temperature optimization, grade selection, mechanical assistance | Appropriate grade selection, process optimization, equipment selection |

| Scale-up Challenges | Different mixing dynamics, heat transfer limitations | Pilot testing, equipment modification, process adaptation | Scale-up studies, equipment qualification, process validation |

Viscosity inconsistencies often indicate problems with dissolution conditions or HPMC quality. Standardizing water temperature, agitation parameters, and addition rates helps ensure consistent results. Regular calibration of process equipment and testing of incoming HPMC batches also contributes to consistency.

Excessive dissolution time impacts production efficiency. This issue may be addressed by:

- Selecting an HPMC grade with appropriate particle size

- Optimizing water temperature within acceptable ranges

- Using more efficient mixing equipment

- Implementing the combined hot/cold method

- Considering alternative dissolution techniques for specific applications

Scale-up challenges emerge when transitioning from laboratory to production scale. The changed mixing dynamics and heat transfer characteristics require careful process adaptation. Pilot-scale testing provides valuable insights for successful scale-up.

6. How Can You Test and Verify Complete HPMC Dissolution?

Confirming complete HPMC dissolution is essential for quality assurance. Multiple testing approaches provide complementary information about solution quality.

Visual inspection serves as the first line of evaluation. A properly dissolved HPMC solution should be clear to slightly translucent, depending on concentration and grade. Observed against a dark background with strong lighting, the solution should be free from visible particles, gel lumps, and haze.

Voglio essere chiaro – visual inspection alone is insufficient for critical applications. Instrumental methods provide more objective and sensitive assessments of dissolution quality.

Viscosity measurement offers valuable insights into dissolution completeness. Incompletely dissolved HPMC typically shows lower-than-expected viscosity initially, followed by increasing viscosity during storage as dissolution continues. Consistent viscosity readings over time indicate complete dissolution.

| Metodo di prova | Equipment | What It Measures | Sensitivity Level | Best For |

|---|---|---|---|---|

| Ispezione visiva | Light box, magnifier | Visible particles, clarity | Basso | Quick assessment, large particles |

| Viscosity Measurement | Viscometer, rheometer | Solution rheology, consistency | Medio | Process control, batch comparison |

| Particle Size Analysis | Laser diffraction, microscopy | Undissolved particle detection | Alto | Quality assurance, R&D |

| Transmittance Testing | Spectrophotometer | Solution clarity, dissolved state | Medio-Alto | Clear solutions, pharmaceutical applications |

| Stability Testing | Various instruments | Long-term performance | Variabile | Final product quality, shelf-life assessment |

Particle size analysis techniques detect undissolved HPMC fragments that may be invisible to the naked eye. Laser diffraction instruments can identify particles in the micron range, while microscopy provides visual confirmation of particle characteristics.

Quality control procedures typically combine multiple testing approaches:

- Initial visual inspection during processing

- Viscosity testing after the expected dissolution period

- Particle analysis for critical applications

- Application-specific testing (e.g., film formation, binding strength)

- Stability assessment under storage conditions

Stability testing evaluates how the dissolved HPMC solution performs over time. Changes in viscosity, clarity, or functionality during storage may indicate incomplete initial dissolution or incompatibility with other ingredients.

Conclusione

Achieving optimal dissolution of hydroxypropyl methylcellulose requires understanding its unique properties and implementing appropriate techniques. The best dissolution method depends on your specific application requirements, available equipment, and HPMC grade characteristics. For most applications, the cold water dispersion technique offers the best balance of simplicity and effectiveness, while the hot/cold method provides advantages for higher concentrations.

Key factors for successful dissolution include controlled addition rates, appropriate temperature management, adequate agitation, and sufficient hydration time. By addressing these variables systematically, you can avoid common problems like lump formation and inconsistent viscosity.

Remember that different industries have developed specialized approaches to HPMC dissolution based on their unique requirements. Whether you’re in pharmaceuticals, construction, food production, or another sector, adapting these industry-specific techniques can improve your results.

For ongoing process optimization, implement robust testing protocols to verify complete dissolution. Combining visual inspection with instrumental methods provides comprehensive quality assurance and helps maintain consistent product performance.

Sezione FAQ

Q1: Can HPMC be dissolved directly in hot water?

No, HPMC should not be dissolved directly in hot water alone. When added to hot water (above 85°C), HPMC forms a hydrated outer layer that prevents water penetration to the core, resulting in lumps or “fish eyes.” The recommended approach is either using cold water or the hot/cold method where HPMC is first dispersed in hot water and then cooled to complete dissolution.

Q2: How long does it typically take to dissolve HPMC completely?

Complete dissolution time varies from 30 minutes to several hours depending on concentration, grade, particle size, temperature, and agitation method. Lower concentrations (0.5-1%) of fine-particle HPMC in cold water with good agitation may dissolve in 30-60 minutes. Higher concentrations (2-5%) or coarser grades may require 2-4 hours or longer for complete hydration and dissolution.

Q3: What’s the difference in dissolution methods between pharmaceutical and construction grade HPMC?

Pharmaceutical grade HPMC dissolution typically emphasizes purity, sterility, and documentation with precise temperature control and filtered water systems. Construction grade HPMC is often pre-blended with dry ingredients before water addition or pre-dissolved as a concentrated solution. Pharmaceutical applications require validated procedures and more rigorous testing, while construction applications focus on scale efficiency and compatibility with other building material components.

Q4: Does the molecular weight of HPMC affect the dissolution process?

Yes, molecular weight significantly affects HPMC dissolution. Higher molecular weight grades (higher viscosity types) generally dissolve more slowly and require more careful dispersion to prevent lump formation. They also develop higher solution viscosity during dissolution, which can impede mixing efficiency. Lower molecular weight grades dissolve more rapidly but may require different agitation parameters to achieve uniform dispersion.

Q5: Can additives improve the dissolution rate of HPMC?

Yes, certain additives can improve HPMC dissolution. Anti-lumping agents like silica can help prevent agglomeration during the initial wetting phase. Some surfactants can accelerate wetting and dissolution by reducing surface tension. Certain salts may affect dissolution rate by altering the polymer’s hydration behavior. However, compatibility with the final application must be considered, as these additives may affect product performance or introduce regulatory concerns in sensitive applications like pharmaceuticals or food products.