Hydroxypropyl Methylcellulose (HPMC) is a versatile semi-synthetic polymer widely used across pharmaceutical, construction, food, and personal care industries. Its unique physicochemical properties make it an invaluable excipient and functional additive in countless formulations. This article examines the critical physicochemical characteristics that determine HPMC’s performance in various applications. Understanding these properties is essential for formulation scientists, product developers, and purchasing managers who need to select the optimal HPMC grade for specific applications. By exploring the molecular structure, solubility, rheology, and other key properties, this article provides practical insights for optimizing HPMC use in industrial products.

1. What Is The Molecular Structure That Defines HPMC’s Physicochemical Nature?

Hydroxypropyl Methylcellulose is a cellulose ether derived from natural cellulose through chemical modification. The transformation process involves treating cellulose with sodium hydroxide followed by reaction with methyl chloride and propylene oxide to introduce methoxyl and hydroxypropyl substituents onto the cellulose backbone.

Ecco cosa lo rende speciale: The precise arrangement and ratio of these substituents create HPMC’s unique physicochemical profile, allowing formulators to select grades with properties tailored to specific applications.

The chemical composition of HPMC consists of a cellulose backbone with varying degrees of methoxyl and hydroxypropyl substitution. The methoxyl groups contribute hydrophobic character, while hydroxypropyl groups enhance hydrophilicity, creating an amphiphilic molecule with balanced properties.

| Parametro strutturale | Gamma tipica | Metodo di misurazione | Impatto sulle proprietà |

|---|---|---|---|

| Contenuto di metossile (%) | 16.5-30 | Cromatografia gassosa | Un contenuto più elevato aumenta la solubilità organica e la gelificazione termica |

| Contenuto di idrossipropile (%) | 4-32 | Cromatografia gassosa | Higher content improves water solubility and surface activity |

| Grado di sostituzione (DS) | 1.2-2.0 | NMR spectroscopy | Determina l'equilibrio idrofilo/idrofobico complessivo |

| Peso molecolare (Dalton) | 10,000-1,500,000 | GPC/SEC | Determina la viscosità e la resistenza meccanica |

Substitution patterns in HPMC are not uniform along the cellulose chain but follow a statistical distribution. The three hydroxyl groups in each anhydroglucose unit have different reactivity, resulting in preferential substitution at certain positions. This non-uniform substitution contributes to HPMC’s complex solution behavior.

Molecular weight distribution significantly influences HPMC’s functional properties. Commercial HPMC grades typically have polydispersity indices between 2 and 5, indicating a relatively broad distribution of chain lengths. This distribution affects solution viscosity, mechanical properties of films, and dissolution kinetics.

2. How Do The Solubility Properties Of HPMC Influence Its Applications?

The solubility characteristics of HPMC represent one of its most commercially significant physicochemical properties, directly influencing its functionality across diverse applications.

What you might find surprising is that HPMC exhibits unusual temperature-dependent solubility behavior that can be strategically leveraged in various manufacturing processes and applications.

La solubilità dipendente dalla temperatura è forse la caratteristica di solubilità più distintiva dell'HPMC. A differenza della maggior parte dei materiali che diventano più solubili all'aumentare della temperatura, l'HPMC mostra un comportamento di solubilità inverso. A temperature inferiori (tipicamente inferiori a 50 °C), l'HPMC si dissolve facilmente in acqua formando soluzioni trasparenti. All'aumentare della temperatura, la solubilità diminuisce fino a raggiungere una temperatura di precipitazione (tipicamente 65-90 °C), punto in cui il polimero subisce una separazione di fase e forma un gel termoindurente.

| Intervallo di temperatura | Comportamento di solubilità dell'HPMC | Implicazioni applicative | Considerazioni sull'elaborazione |

|---|---|---|---|

| Sotto i 5°C | Dissoluzione lenta, alta viscosità | Tempo di idratazione prolungato necessario | La predispersione in acqua calda può essere utile |

| 5-30°C | Dissoluzione ottimale, soluzioni stabili | Ideale per la maggior parte delle applicazioni acquose | Condizioni di lavorazione standard idonee |

| 30-50°C | Solubilità decrescente, chiarezza mantenuta | È richiesto un attento controllo della temperatura | Monitorare le variazioni di viscosità durante la lavorazione |

| 50-70°C | Avvicinandosi all'insolubilità, aumentando la torbidità | Può causare instabilità nella formulazione | Considerare la tecnica caldo/freddo per la dispersione |

| Sopra i 70°C | Insolubile, forma un gel termoindurente | Può essere utilizzato come barriera funzionale | Richiede raffreddamento per la ridissoluzione |

Solvent compatibility extends beyond water to include various mixed solvent systems. HPMC is soluble in many binary water-organic solvent mixtures, with solubility depending on the organic component and the HPMC substitution pattern. Typically, HPMC with higher methoxyl content shows better compatibility with organic solvents such as ethanol and propylene glycol.

Dissolution kinetics involve several stages. Initially, water penetrates the polymer particles, causing swelling and gel layer formation around each particle. As hydration continues, polymer chains disentangle and diffuse into the bulk solution. The rate-limiting step is typically the disentanglement and diffusion phase, influenced by particle size, molecular weight, and substitution pattern.

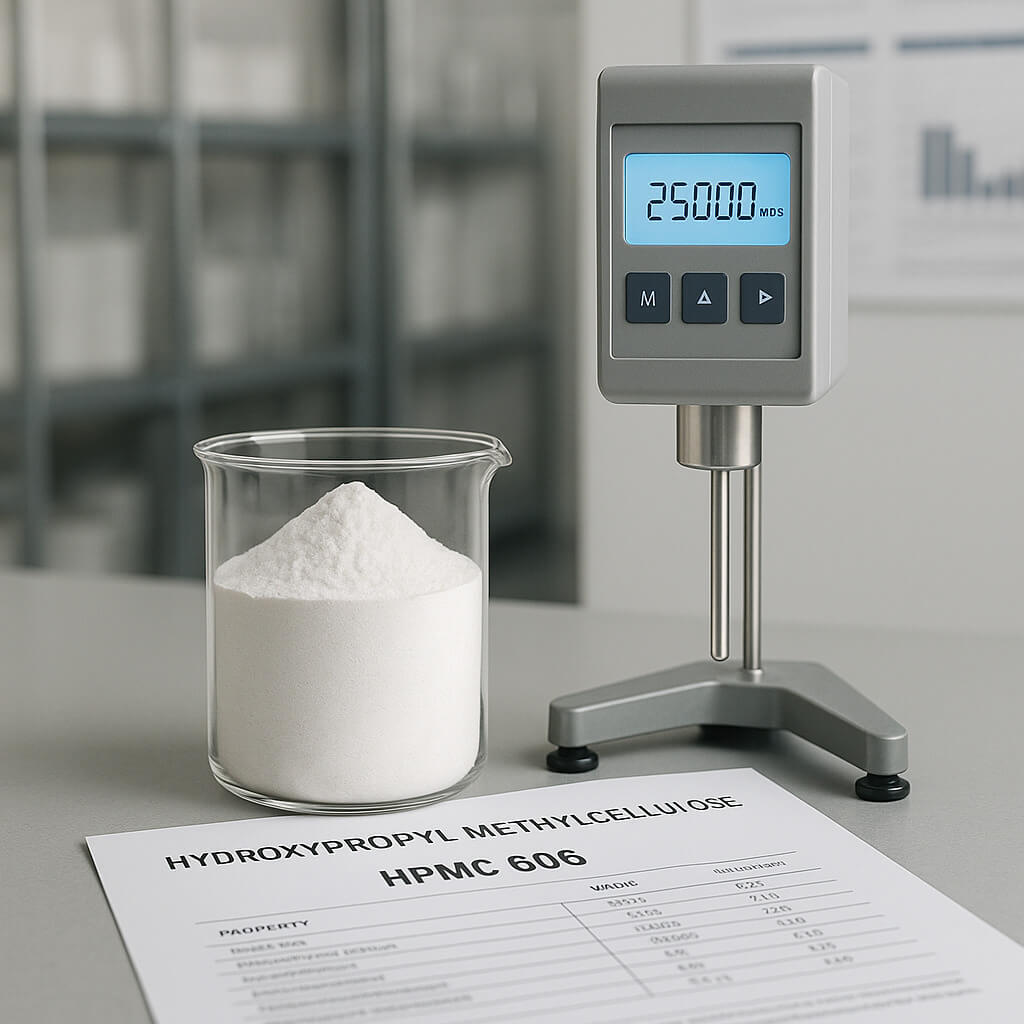

3. What Rheological Characteristics Make HPMC Valuable In Various Industries?

The rheological properties of HPMC—its flow and deformation behavior in solution—represent some of its most commercially valuable physicochemical characteristics. These properties determine how HPMC functions as a thickener, stabilizer, and processing aid.

Here’s the key insight: HPMC’s complex rheological behavior combines several beneficial properties that would typically require multiple additives, allowing formulators to achieve desired flow characteristics with a single ingredient.

Viscosity profiles across concentration ranges follow a power law relationship, with viscosity increasing exponentially as concentration increases. This relationship typically follows the equation η = K·C^a, where η is viscosity, C is concentration, and K and a are constants specific to the HPMC grade.

| Proprietà reologica | Metodo di misurazione | Valori tipici | Significato dell'applicazione |

|---|---|---|---|

| Viscosità apparente | Viscosimetro rotazionale | 3-200.000 mPa·s (soluzione 2%) | Determina il comportamento del flusso e l'efficienza di addensamento |

| Stress di snervamento | Test di rampa di stress | 0,5-20 Pa (soluzione 2%) | Controlla la resistenza all'abbassamento e la stabilità delle sospensioni |

| Indice di tissotropia | Area del ciclo di isteresi | 1.1-2.5 | Indica il recupero dipendente dal tempo dopo il taglio |

| Modulo di immagazzinamento (G') | Test oscillatorio | 1-500 Pa | Riflette la componente elastica e la forza del gel |

| Loss Modulus (G”) | Test oscillatorio | 0.5-200 Pa | Indicates viscous component and flowability |

Shear-dependent flow behavior is another critical rheological characteristic of HPMC solutions. HPMC exhibits pseudoplastic (shear-thinning) behavior, where viscosity decreases as shear rate increases. This property provides significant processing advantages—solutions flow readily during high-shear operations like mixing, pumping, or spraying, but maintain higher viscosity at rest to provide stability.

Thixotropic and pseudoplastic properties often coexist in HPMC solutions. While pseudoplasticity refers to instantaneous viscosity reduction under shear, thixotropy involves time-dependent viscosity recovery after shearing stops. HPMC solutions typically show moderate thixotropy, with viscosity gradually returning to its original value after shear is removed.

4. How Do Surface And Interfacial Properties Of HPMC Affect Formulation Performance?

Le proprietà superficiali e interfacciali dell'HPMC svolgono un ruolo cruciale in numerose applicazioni, influenzando fenomeni come la bagnatura, la distribuzione, l'emulsione e la stabilizzazione. Queste proprietà derivano dalla natura anfifilica dell'HPMC, che contiene sia gruppi idrofili che idrofobi.

Ciò che rende questo particolarmente prezioso is that HPMC provides moderate surface activity without the drawbacks often associated with conventional surfactants, such as irritation potential or excessive foaming.

Le capacità di modifica della tensione superficiale dell'HPMC sono significative, sebbene meno pronunciate rispetto a quelle dei tensioattivi convenzionali. L'HPMC riduce tipicamente la tensione superficiale dell'acqua da circa 72 mN/m a 42-55 mN/m, a seconda del grado e della concentrazione.

| Proprietà superficiale/interfacciale | Metodo di misurazione | Valori tipici | Impatto della formulazione |

|---|---|---|---|

| Riduzione della tensione superficiale | Metodo dell'anello di Du Noüy | 42-55 mN/m (soluzione 1%) | Migliora la bagnatura e la distribuzione |

| Tensione interfacciale (olio/acqua) | Metodo della goccia rotante | 15-25 mN/m | Facilita la formazione dell'emulsione |

| Angolo di contatto sulla superficie idrofobica | Goniometro | 40-65° | Migliora la bagnatura del substrato |

| Concentrazione di aggregazione critica | Grafico della tensione superficiale | 0,01-0,1% p/v | Determina la concentrazione minima efficace |

Interfacial activity at liquid-liquid boundaries enables HPMC to function as an emulsion stabilizer. At oil-water interfaces, HPMC molecules orient with hydrophobic groups toward the oil phase and hydrophilic groups toward the water phase, reducing interfacial tension and forming a protective layer around droplets.

Adsorption behavior at solid-liquid interfaces makes HPMC valuable in applications involving particle suspensions or interactions with solid surfaces. HPMC adsorbs onto many solid surfaces through hydrogen bonding and hydrophobic interactions, forming a protective layer that prevents particle aggregation through steric stabilization.

5. What Thermal Properties Must Be Considered When Processing HPMC?

The thermal properties of HPMC significantly influence its processing requirements and application performance. Understanding these thermal characteristics is essential for proper material selection and process design.

But here’s what you need to know: L'HPMC presenta un comportamento termico unico che crea sia sfide che opportunità nella lavorazione e nello sviluppo delle applicazioni.

Il fenomeno della gelificazione termica rappresenta la proprietà termica più distintiva dell'HPMC. Quando le soluzioni di HPMC vengono riscaldate oltre una temperatura critica (tipicamente 65-90 °C, a seconda del grado), subiscono una separazione di fase e formano una struttura di gel reversibile.

| Proprietà termica | Metodo di misurazione | Valori tipici | Implicazioni di elaborazione |

|---|---|---|---|

| Temperatura di gelificazione | Punto di torbidità, metodi reologici | 65-90°C (a seconda del grado) | Determina la temperatura massima di elaborazione in soluzione |

| Temperatura di transizione vetrosa (Tg) | Calorimetria differenziale a scansione | 170-190°C | Influisce sulla stabilità dell'elaborazione e dello stoccaggio allo stato solido |

| Inizio della stabilità termica | Analisi termogravimetrica | 190-220°C | Imposta il limite massimo di temperatura per l'elaborazione |

| Temperatura di decomposizione | Analisi termogravimetrica | 280-300°C | Parametro di sicurezza critico per la lavorazione ad alta temperatura |

La temperatura di transizione vetrosa (Tg) per l'HPMC secco varia tipicamente tra 170 e 190 °C, sebbene questa possa essere significativamente ridotta dall'umidità o dai plastificanti. La Tg rappresenta la temperatura alla quale l'HPMC passa da uno stato vetroso e fragile a uno stato più gommoso e flessibile.

Thermal stability and degradation pathways are critical considerations for processing HPMC. The polymer begins to show signs of degradation at temperatures above 190-220°C, with significant decomposition occurring above 280-300°C. Degradation typically involves chain scission, resulting in reduced molecular weight and altered functional properties.

6. How Do The Binding And Film-Forming Properties Of HPMC Function?

The binding and film-forming capabilities of HPMC represent some of its most valuable functional properties, enabling applications ranging from pharmaceutical tablet formulation to construction adhesives and food coatings.

The critical factor to understand is that HPMC forms cohesive films and binding matrices through multiple physicochemical mechanisms, creating versatile performance characteristics that can be tailored to specific application requirements.

Adhesion mechanisms to various substrates involve several types of interactions. On polar surfaces like cellulose, glass, or metal oxides, HPMC adheres primarily through hydrogen bonding. On less polar surfaces, adhesion occurs through van der Waals forces and hydrophobic interactions with the methoxyl groups.

| Film/Binding Property | Metodo di misurazione | Fattori influenzanti | Application Relevance |

|---|---|---|---|

| Resistenza alla trazione | Tensile testing | Molecular weight, Concentration | Determines film durability and handling properties |

| Elongation at Break | Tensile testing | Tipo di sostituzione, Contenuto di plastificante | Affects flexibility and resistance to cracking |

| Adhesive Strength | Peel or shear tests | Surface chemistry, Application method | Critical for binding and coating applications |

| Water Vapor Transmission Rate | Cup method, ASTM E96 | Film thickness, Substitution pattern | Determines moisture barrier properties |

The film formation process involves several stages. Initially, HPMC dissolves in water or a water-alcohol mixture to form a solution. As the solvent evaporates, polymer concentration increases, causing chain entanglement and eventual coalescence into a continuous film.

Le proprietà meccaniche dei film HPMC possono essere controllate con precisione attraverso la selezione del grado e la formulazione. La resistenza alla trazione aumenta tipicamente con il peso molecolare, mentre le proprietà di allungamento sono influenzate dal tipo di sostituzione: un contenuto più elevato di idrossipropile produce generalmente film più flessibili.

7. What Analytical Methods Are Used To Characterize HPMC’s Physicochemical Properties?

Accurate characterization of HPMC’s physicochemical properties is essential for quality control, product development, and regulatory compliance. Various analytical techniques provide complementary information about different aspects of HPMC’s structure and behavior.

What’s particularly important to recognize is that comprehensive characterization requires multiple analytical approaches, as no single method can fully capture HPMC’s complex physicochemical profile.

Spectroscopic techniques for structural analysis provide information about HPMC’s chemical composition and substitution patterns. Fourier Transform Infrared Spectroscopy (FTIR) identifies characteristic absorption bands associated with methoxyl and hydroxypropyl substituents. Nuclear Magnetic Resonance (NMR) spectroscopy provides more detailed information about substitution patterns.

| Analytical Method | Information Provided | Sample Preparation | Limitazioni |

|---|---|---|---|

| Gas Chromatography | Methoxyl and hydroxypropyl content | Hydrolysis and derivatization | Destructive, no positional information |

| Size Exclusion Chromatography | Distribuzione del peso molecolare | Dissolution in mobile phase | Requires calibration standards |

| Differential Scanning Calorimetry | Thermal transitions, glass transition temperature | Minimal preparation | Complex interpretation for heterogeneous samples |

| Rheometry | Viscosity profiles, viscoelastic properties | Solution preparation | Results depend on measurement conditions |

Chromatographic methods for molecular weight determination primarily rely on Size Exclusion Chromatography (SEC), also known as Gel Permeation Chromatography (GPC). This technique separates HPMC molecules based on their hydrodynamic volume, with larger molecules eluting earlier than smaller ones.

Thermal analysis approaches include Differential Scanning Calorimetry (DSC), which measures heat flow associated with thermal transitions such as the glass transition temperature (Tg). Thermogravimetric Analysis (TGA) monitors weight loss during heating, providing information about moisture content, thermal stability, and decomposition pathways.

Conclusione

The physicochemical properties of Hydroxypropyl Methylcellulose (HPMC) represent a complex interplay of structural features, molecular interactions, and environmental responses that collectively determine its performance across diverse applications. From its unique molecular structure and substitution pattern to its solubility, rheological, surface, thermal, and film-forming properties, HPMC offers a versatile functionality profile that few other polymers can match.

Understanding these properties allows formulators and technical professionals to select the optimal HPMC grade for specific applications and to anticipate how the material will behave under various processing and use conditions. The interrelated nature of these properties means that changing one parameter—such as substitution pattern or molecular weight—often affects multiple functional characteristics, requiring a holistic approach to grade selection and formulation development.

Per i produttori e gli sviluppatori di prodotti che lavorano con HPMC, questa conoscenza si traduce in una selezione più efficiente dei materiali, migliori prestazioni del prodotto e costi potenzialmente ridotti grazie all'ottimizzazione della formulazione.

Domande frequenti

Q1: How do the physicochemical properties of HPMC vary between different commercial grades?

Commercial HPMC grades vary primarily in three key physicochemical properties: viscosity (determined by molecular weight), substitution type (ratio and distribution of methoxyl and hydroxypropyl groups), and particle size. Viscosity grades range from 3 mPa·s to over 200,000 mPa·s (2% solution), directly affecting thickening efficiency, film strength, and binding capacity. Substitution types are classified by pharmacopeia designations (e.g., HPMC 2208, 2906, 2910), with higher methoxyl content increasing thermal gelation and organic solubility, while higher hydroxypropyl content improves cold water solubility and surface activity. Particle size grades range from fine (20-75 microns) to coarse (125-250 microns), affecting dissolution rate and flow properties.

Q2: What impact do storage conditions have on the stability of HPMC’s physicochemical properties?

Storage conditions significantly influence the stability of HPMC’s physicochemical properties. Temperature extremes should be avoided—high temperatures (>40°C) can cause gradual degradation through oxidation or hydrolysis, potentially reducing molecular weight and viscosity. Humidity control is crucial, as HPMC can absorb moisture from the air, potentially leading to caking, viscosity changes, or microbiological growth if moisture content exceeds 10%. Light exposure, particularly UV radiation, may contribute to oxidative degradation over extended periods. Proper packaging in moisture-resistant containers and storage in cool, dry conditions (ideally 15-30°C, <60% relative humidity) help maintain HPMC’s physicochemical properties.

Q3: How do the physicochemical properties of HPMC compare to other cellulose ethers?

HPMC offers a distinct physicochemical profile compared to other cellulose ethers. Versus Methylcellulose (MC), HPMC provides better cold water solubility and lower thermal gelation temperatures, though MC forms stronger gels. Compared to Carboxymethylcellulose (CMC), HPMC is non-ionic and thus maintains stable viscosity across a wider pH range but provides less electrolyte tolerance and lower viscosity efficiency. Hydroxyethylcellulose (HEC) provides higher clarity in solution than HPMC but lacks thermal gelation properties and has lower surface activity. Ethylcellulose (EC) is water-insoluble unlike HPMC, making it suitable for water-resistant applications. Hydroxypropylcellulose (HPC) offers better organic solubility than HPMC but typically at higher cost.

Q4: Which physicochemical properties are most critical for pharmaceutical applications of HPMC?

For pharmaceutical applications, the most critical physicochemical properties of HPMC depend on the specific dosage form and function. In controlled-release matrix tablets, viscosity grade and substitution type directly determine drug release kinetics—higher viscosity grades create more robust gel layers that slow drug diffusion, while substitution type affects the hydration rate and gel strength. For tablet film coatings, molecular weight and substitution type influence film formation, adhesion, and dissolution characteristics, with HPMC 2910 (high methoxyl) often preferred for its film properties. In capsule manufacturing, thermal gelation temperature and gel strength are crucial for shell integrity. For ophthalmic solutions, solution clarity, viscosity stability, and biocompatibility are essential.

Q5: Can the physicochemical properties of HPMC be modified post-manufacturing?

While the fundamental molecular properties of HPMC (substitution pattern and molecular weight) are fixed during manufacturing, several post-production modifications can alter its functional physicochemical properties. Physical modifications include particle size reduction through milling to increase dissolution rate, surface treatment with glyoxal or other agents to improve dispersibility, and agglomeration to enhance flow properties. Blending different HPMC grades can achieve intermediate properties or performance profiles not available from standard grades. Formulation approaches can significantly modify HPMC functionality—adding salts to alter solution properties, combining with other polymers for synergistic effects, or incorporating plasticizers to modify film characteristics.