Hydroxypropyl Methylcellulose (HPMC) is a versatile cellulose derivative that has found a wide range of applications across various industries. Its ability to modify the viscosity, solubility, and texture of formulations makes it highly valuable in pharmaceuticals, food, construction, and cosmetics. This article explores the properties of HPMC, its different uses, and the benefits it offers to industries. By the end, you will have a clearer understanding of why HPMC is so widely used and how its unique characteristics can benefit your business.

1. What Are the Properties of HPMC?

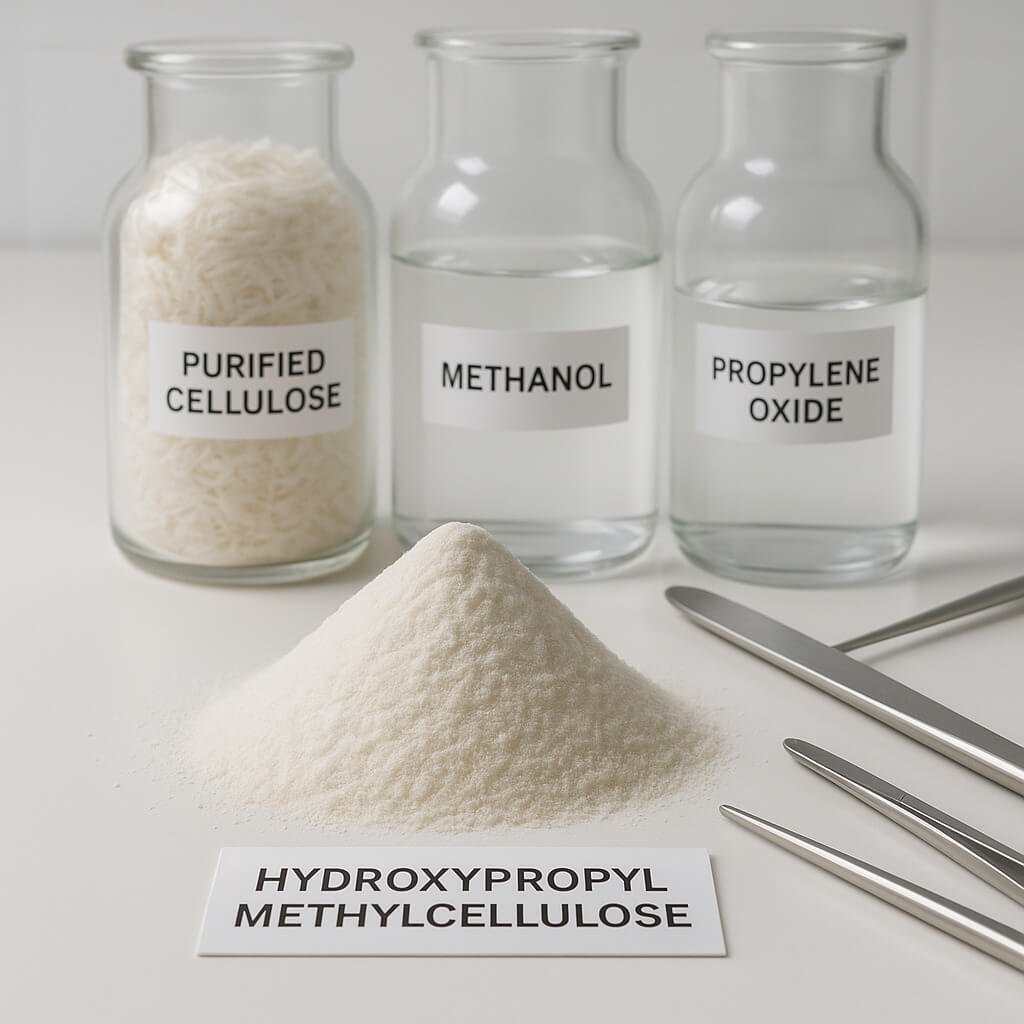

HPMC is a cellulose ether made by chemically modifying cellulose through the introduction of hydroxypropyl and methyl groups. These modifications make HPMC water-soluble and enhance its ability to interact with various substances, making it ideal for numerous applications. But here’s the kicker… its versatility lies in the ability to adjust its solubility and viscosity, tailoring it to the needs of specific industries.

The primary properties of HPMC are its solubility in both hot and cold water, which ensures it can be used in a wide range of temperatures. It also offers excellent film-forming, thickening, and gelling properties, allowing it to stabilize emulsions and suspensions. In pharmaceutical formulations, HPMC is often used to control the release rate of drugs, ensuring that active ingredients are delivered at the right time and dosage.

The viscosity of HPMC can also be adjusted by altering its molecular weight and degree of substitution. These properties are key to its use in different industries, where the right balance of solubility and viscosity can make all the difference in product performance.

| Proprietà | Caratteristiche | Applicazioni |

|---|---|---|

| Solubilità | Soluble in hot and cold water | Pharmaceuticals, Food, Cosmetics |

| Viscosità | Adjustable viscosity | Construction (adhesives, mortars), Food, Pharma |

| Film-forming | Excellent film-forming agent | Tablet coatings, Cosmetics (creams, lotions) |

2. How Does the Molecular Structure of HPMC Affect Its Properties?

The molecular structure of HPMC plays a crucial role in determining its physicochemical properties. Ready for the good part? The degree of substitution, which refers to the number of hydroxyl groups replaced by hydroxypropyl and methyl groups, significantly influences the solubility, viscosity, and gel formation of HPMC. The higher the degree of substitution, the more soluble and viscous the compound becomes, making it suitable for a variety of industrial applications.

For instance, in pharmaceutical applications, the molecular structure of HPMC allows it to be used in controlled-release formulations. The hydroxypropyl and methyl groups enhance its ability to form gels, which can regulate the release rate of active ingredients. In food and cosmetics, these modifications ensure that HPMC can be used as a thickener, stabilizer, and emulsifier, providing the necessary texture and stability for products like sauces, lotions, and shampoos.

In construction, HPMC’s molecular structure helps to improve the workability and water retention of materials like adhesives and mortars. The methyl and hydroxypropyl groups contribute to better adhesion, flexibility, and reduced drying times, making it easier to apply these materials in various conditions.

| Grado di sostituzione | Impact on Properties | Usi comuni |

|---|---|---|

| Basso | Low viscosity, fast dissolution | Cosmetics (creams, lotions), Food |

| Medio | Viscosità moderata | Pharmaceuticals (tablets), Construction |

| Alto | High viscosity, slow dissolution | Controlled-release formulations, Mortars |

3. Why is HPMC Used in Pharmaceuticals?

HPMC is widely used in the pharmaceutical industry due to its ability to modify the physical properties of a formulation. But here’s the kicker… its role in controlled drug release is one of the main reasons why it’s so essential. In tablet formulations, HPMC acts as a binder, helping to hold the tablet together and ensuring the active ingredients are evenly distributed.

One of the most common uses of HPMC in pharmaceuticals is in controlled-release systems. The viscosity of HPMC allows it to form a gel matrix, which can slowly release the active ingredient over time. This is particularly beneficial for drugs that need to be released gradually to maintain their efficacy, such as painkillers, antihypertensive drugs, and anti-inflammatory medications.

HPMC is also used in liquid formulations, where it serves as a suspending agent. It keeps the active ingredients evenly dispersed in the solution, preventing settling and ensuring uniform dosage. Additionally, HPMC’s biocompatibility and low toxicity make it a safe choice for use in pharmaceutical products.

| Applicazione | Funzione dell'HPMC | Benefici |

|---|---|---|

| Tablet Formulations | Binder, controlled-release agent | Ensures uniform drug release, stability |

| Formulazioni liquide | Suspensions, stabilizer | Even dispersion of active ingredients |

| Controlled-Release Systems | Regulates dissolution rate | Sustained drug delivery, improved patient compliance |

4. How Does HPMC Benefit the Food Industry?

In the food industry, HPMC plays a vital role in ensuring the texture, stability, and consistency of various products. Ready for the good part? HPMC’s ability to act as a stabilizer and emulsifier makes it a go-to ingredient in both processed and plant-based foods.

Low viscosity HPMC is commonly used in food products like sauces, dressings, and dairy alternatives, where it helps create smooth textures and prevents ingredient separation. It improves the texture and mouthfeel of plant-based beverages, making them more appealing to consumers. In dairy products, HPMC helps to maintain a uniform consistency, preventing separation and improving the product’s shelf life.

HPMC is also a critical ingredient in gluten-free and low-fat products. It is used to improve the texture and stability of baked goods and other processed foods that may lack the structure provided by gluten. By adding HPMC, manufacturers can improve the overall quality and mouthfeel of their products without adding unnecessary calories or fat.

| Applicazione | Ruolo dell'HPMC | Product Benefits |

|---|---|---|

| Prodotti lattiero-caseari | Stabilizer, emulsifier | Prevents separation, improves texture |

| Alimenti a base vegetale | Texture enhancer, emulsifier | Mimics dairy texture, improves mouthfeel |

| Baked Goods | Gluten replacement, texture enhancer | Better texture, stable formulation |

5. How is HPMC Applied in the Construction Industry?

In construction, HPMC is primarily used in adhesives, mortars, and plasters, where its ability to improve workability, adhesion, and water retention is essential. What’s the real story? HPMC helps make construction materials more efficient to use, while also enhancing their performance.

Low viscosity HPMC is particularly useful in tile adhesives, where it improves spreadability and ease of application. Its ability to retain moisture ensures that the adhesive remains workable for a longer period, allowing workers to adjust tiles during installation. Similarly, in mortar formulations, HPMC helps retain moisture, preventing the mixture from drying out too quickly and ensuring that it cures properly.

In plaster, HPMC’s role is to improve consistency and texture. It helps create a smoother, more uniform finish, and its water retention properties ensure that the plaster remains workable during application. These advantages make HPMC a vital ingredient in a wide range of construction materials.

| Applicazione | Ruolo dell'HPMC | Impatto sulle prestazioni |

|---|---|---|

| Mortai | Water retention, adhesion | Improved workability, enhanced bonding |

| Adesivi per piastrelle | Spreadability, moisture retention | Easier application, better adhesion |

| Cerotti | Texture improvement, consistency | Smoother finish, longer workability |

6. What are the Benefits of HPMC in Cosmetics and Personal Care Products?

HPMC’s versatility extends to the cosmetics and personal care industry, where it is used to improve the texture, stability, and performance of a wide variety of products. Ready for the good part? Its ability to thicken and stabilize emulsions makes it an essential ingredient in creams, lotions, and shampoos.

In lotions and creams, HPMC helps to achieve a smooth, silky texture without being greasy. It also ensures that the product remains stable over time, preventing separation of the ingredients. In shampoos and conditioners, HPMC provides the necessary viscosity and improves the product’s ability to spread evenly, creating a more pleasant user experience.

Moreover, HPMC is used in gels and sunscreens for its ability to form clear, stable gels that do not separate. Its thickening properties are especially useful in creating high-quality cosmetic formulations that meet consumer expectations for smoothness, consistency, and stability.

| Applicazione | Ruolo dell'HPMC | Product Benefits |

|---|---|---|

| Creams & Lotions | Thickener, stabilizer | Smooth texture, stable formulation |

| Shampoo e balsami | Viscosity control, emulsifier | Improved spreadability, better texture |

| Sunscreens & Gels | Gel formation, thickener | Clear gels, enhanced stability |

7. What Are the Environmental and Economic Impacts of HPMC?

HPMC offers significant environmental and economic benefits, making it an attractive choice for industries looking to reduce their environmental footprint and production costs. But here’s the kicker… HPMC is biodegradable and derived from renewable resources, making it an eco-friendly alternative to many synthetic chemicals.

The environmental benefits of HPMC are evident in its use in sustainable and eco-friendly formulations. For example, in the food industry, HPMC is used as a stabilizer in plant-based products, which are gaining popularity due to their lower environmental impact. Additionally, HPMC is often used in pharmaceuticals and cosmetics as a safe, biodegradable option for various formulations.

From an economic perspective, HPMC is cost-effective for large-scale production, especially when compared to other materials that may require more complex or costly manufacturing processes. Its ability to be used in a variety of industries, coupled with its performance-enhancing properties, makes it a highly cost-efficient ingredient.

| Beneficio | Impatto ambientale | Economic Impact |

|---|---|---|

| Biodegradabilità | Reduces environmental footprint | Sustainable and eco-friendly options |

| Versatilità | Widely applicable in multiple industries | Cost-effective, scalable production |

| Renewable Resources | Derived from cellulose | Costi di produzione inferiori |

8. How Do You Measure and Control the Properties of HPMC?

Measuring and controlling the properties of HPMC is essential to ensure consistent quality and performance across different applications. Ready for the good part? There are several methods to accurately measure HPMC’s viscosity, solubility, and other properties, depending on the needs of the specific industry.

The viscosity of HPMC is typically measured using a Brookfield viscometer or a rotational viscometer. These tools allow manufacturers to assess how the compound behaves under different shear rates, providing valuable data that helps in optimizing formulations. Solubility is also monitored to ensure that HPMC dissolves effectively in the desired solvents, whether water or organic compounds.

Control of HPMC properties is achieved by adjusting factors like concentration, molecular weight, and degree of substitution. These adjustments allow manufacturers to tailor HPMC’s performance for specific applications, ensuring that the final product meets the required standards.

| Metodo | Scopo | Equipment Used |

|---|---|---|

| Viscosimetro Brookfield | Misura la viscosità a diverse velocità di taglio | Brookfield LV, RV models |

| Viscosimetro rotazionale | Measures flow under varying conditions | Advanced rheometers and rotational viscometers |

| Concentration Control | Adjusts viscosity by modifying HPMC concentration | Precise measurement of HPMC input |

9. What Are the Challenges in Using HPMC Across Various Industries?

Despite its many benefits, HPMC does present certain challenges when used across different industries. One of the main challenges is the variability in performance depending on the grade of HPMC used. The degree of substitution and molecular weight can affect its viscosity, solubility, and stability, which means manufacturers must select the correct grade for each application.

Additionally, HPMC can interact with other ingredients in formulations, particularly in food and pharmaceutical products. This can lead to instability or unexpected changes in texture, requiring careful testing and formulation adjustments.

What’s the real story? While HPMC is highly versatile, it’s essential to conduct thorough testing and select the appropriate grade to ensure optimal performance in each application.

| Sfida | Impatto sulle prestazioni | Soluzione |

|---|---|---|

| Grade Variability | Inconsistent results | Select appropriate grade based on needs |

| Ingredient Interactions | Potential instability | Thorough formulation and compatibility testing |

10. What Are the Future Trends for HPMC Usage and Innovation?

The future of HPMC is bright, with innovations in formulation and a growing demand for eco-friendly and sustainable products. Emerging trends suggest an increasing focus on customizing HPMC’s properties to meet the needs of specific industries,

such as personalized medicine in pharmaceuticals or advanced construction materials.

There is also a growing interest in using HPMC for green technologies, where its biodegradable properties make it an ideal candidate for environmentally conscious formulations. As the demand for plant-based and sustainable products increases, HPMC will likely play a pivotal role in creating solutions that meet these consumer preferences.

| Tendenza | Potential Impact | Future Applications |

|---|---|---|

| Personalizzazione | Tailored formulations for specific needs | Farmaceutica, alimentare, edilizia |

| Eco-friendly | Growing demand for sustainable products | Green construction, plant-based products |

Sezione FAQ

Domanda 1: What is HPMC and how is it used in various industries?

HPMC (Hydroxypropyl Methylcellulose) is a cellulose derivative used as a thickening agent, emulsifier, stabilizer, and binder in industries such as pharmaceuticals, food, construction, and cosmetics.

D2: How does HPMC benefit pharmaceutical applications?

HPMC is used in pharmaceutical formulations as a binder, stabilizer, and controlled-release agent. It ensures the uniform distribution of active ingredients and controls the release rate in tablets and suspensions.

D3: What role does HPMC play in the food industry?

In food products, HPMC acts as a stabilizer, emulsifier, and thickening agent, enhancing texture, consistency, and stability, especially in dairy products, plant-based foods, and beverages.

D4: How is HPMC used in construction?

In construction, HPMC is used in mortars, adhesives, and plasters to improve workability, water retention, and adhesion, making it easier to apply and ensuring strong bonding.

D5: What are the environmental and economic benefits of HPMC?

HPMC is biodegradable, derived from renewable resources, and cost-effective for large-scale production. Its use helps manufacturers create sustainable, eco-friendly products while maintaining high performance.