Гидроксипропилметилцеллюлоза (ГПМЦ) — это универсальный полимер, который играет важную роль в различных отраслях промышленности, от фармацевтики до строительства и производства продуктов питания. Известный своей способностью растворяться в воде и образовывать гели, уникальные свойства ГПМЦ делают его ценным ингредиентом во многих рецептурах. В этой статье рассматриваются ключевые свойства ГПМЦ и рассматривается, как они используются в различных промышленных приложениях. От повышения качества продукции до обеспечения экологической устойчивости — понимание преимуществ ГПМЦ имеет важное значение для профессионалов в этой области.

1. Что такое HPMC и как он работает в промышленности?

Гидроксипропилметилцеллюлоза (ГПМЦ) — полусинтетический полимер, полученный путем модификации целлюлозы, натурального растительного материала. Благодаря введению гидроксипропильных и метильных групп ГПМЦ становится водорастворимым, образуя гелеобразные вещества, которые идеально подходят для различных применений. Эта химическая модификация делает ГПМЦ как универсальным, так и функциональным, позволяя ему выполнять широкий спектр задач, таких как загущение, эмульгирование и связывание.

В промышленных условиях способность HPMC растворяться как в холодной, так и в горячей воде делает его отличным выбором для фармацевтических, пищевых и строительных применений. Он используется в таблетированных формулах как связующее, стабилизатор и агент с контролируемым высвобождением в фармацевтической промышленности. В производстве продуктов питания HPMC действует как загуститель и эмульгатор, гарантируя, что продукты сохранят желаемую текстуру и консистенцию. Кроме того, в строительстве водоудерживающие и адгезионные свойства HPMC делают его критически важным ингредиентом в строительных растворах и клеях.

Улучшая эксплуатационные характеристики продукта и обеспечивая постоянное качество, роль ГПМЦ в промышленных приложениях невозможно переоценить. Понимание его свойств помогает производителям оптимизировать рецептуры, повышать стабильность продукта и удовлетворять потребности различных отраслей.

| Промышленность | Приложения | Роль HPMC |

|---|---|---|

| Фармацевтика | Связующие вещества, агенты с контролируемым высвобождением | Последовательность, контролируемое высвобождение препарата |

| Еда | Эмульгаторы, стабилизаторы, загустители | Текстура, консистенция, срок годности |

| Строительство | Растворы, клеи | Водоудержание, обрабатываемость, адгезия |

2. Каковы основные физические и химические свойства ГПМЦ?

Ключевые свойства HPMC делают его предпочтительным выбором в различных промышленных применениях. Эти свойства включают растворимость в воде, контроль вязкости, образование геля, термическая стабильность, и биоразлагаемость. Каждое свойство играет решающую роль в определении функциональности полимера в различных отраслях промышленности.

Растворимость в воде является, пожалуй, самым важным свойством HPMC. Это позволяет полимеру растворяться как в холодной, так и в горячей воде, что делает его идеальным для использования в продуктах, требующих однородной текстуры и стабильности. Независимо от того, используется ли он в фармацевтике для формирования матрицы таблетки или в пищевых продуктах для стабилизации эмульсий, растворимость HPMC обеспечивает стабильные результаты.

Контроль вязкости — еще одна важная функция. ГПМЦ может изменять вязкость растворов, что ценно как в фармацевтических, так и в пищевых рецептурах. В фармацевтике он помогает контролировать текучесть активных ингредиентов в таблетках, а в еде обеспечивает нужную густоту соусов и заправок.

Способность к гелеобразованию делает ГПМЦ особенно полезным в рецептурах с контролируемым высвобождением для лекарств. Образуя гелевую матрицу, он регулирует скорость высвобождения активных ингредиентов, гарантируя, что лекарство высвобождается медленно и последовательно с течением времени.

Термическая стабильность гарантирует, что ГПМЦ сохраняет свои функциональные свойства при воздействии различных температур, что особенно полезно в пищевой и строительной промышленности.

Окончательно, Биоразлагаемость делает HPMC экологически чистым вариантом для отраслей, ищущих устойчивые решения. По мере роста экологических проблем способность HPMC разлагаться естественным образом становится ключевым аргументом в пользу продажи.

| Свойство | Функциональность | Приложение |

|---|---|---|

| Растворимость в воде | Легко растворяется в воде. | Фармацевтика, продукты питания, строительство |

| Контроль вязкости | Регулирует густоту растворов | Фармацевтика, продукты питания |

| Способность к гелеобразованию | Образует гели для контролируемого высвобождения | Фармацевтика, строительство |

| Термическая стабильность | Сохраняет стабильность при различных температурах | Фармацевтика, продукты питания |

| Биоразлагаемость | Разлагается естественным образом | Экологически чистые приложения |

3. Как ГПМЦ используется в фармацевтических составах?

Роль HPMC в фармацевтической промышленности незаменима. Он широко используется в качестве связующее в таблетированных формулах, где он помогает связывать активные ингредиенты вместе, обеспечивая структурную целостность таблетки. Без ГПМЦ таблетки могут рассыпаться или не обеспечивать эффективную доставку активного ингредиента. Образуя однородную и связную массу, ГПМЦ обеспечивает равномерное распределение активных ингредиентов и сохранение таблетки в целости во время обращения и приема внутрь.

Еще одной ключевой функцией ГПМЦ в фармацевтике является его способность контролировать высвобождение лекарственных средств. Препараты с контролируемым высвобождением жизненно важны для обеспечения постепенного высвобождения препарата с течением времени, обеспечивая устойчивый терапевтический эффект. ГПМЦ действует как матрица, которая удерживает препарат и регулирует его высвобождение, обеспечивая стабильную, контролируемую доставку в течение дня.

Кроме того, ГПМЦ используется в местные и трансдермальные продукты. В этих приложениях ГПМЦ образует гели, которые удерживают активные фармацевтические ингредиенты в стабильной матрице, обеспечивая эффективное впитывание кожей. Его гелеобразующая способность гарантирует, что продукт останется нетронутым и что активные ингредиенты будут доставлены последовательно с течением времени.

| Фармацевтическое применение | Функция | Выгода |

|---|---|---|

| Связующее | Удерживает активные ингредиенты вместе | Обеспечивает целостность таблетки, равномерное высвобождение лекарственного средства |

| Контролируемый выпуск | Регулирует высвобождение лекарственных средств | Устойчивый терапевтический эффект, снижение кратности приема |

| Гели и средства местного применения | Образует стабильные матрицы для актуальных продуктов | Эффективное впитывание кожей, стабильность |

4. Каковы преимущества ГПМЦ в производстве продуктов питания и напитков?

В пищевой промышленности ГПМЦ используется в основном как загуститель, эмульгатор, и стабилизатор. Его универсальность в изменении текстуры и консистенции пищевых продуктов делает его незаменимым во многих рецептурах. Как загуститель, HPMC помогает улучшить вкусовые ощущения и вязкость таких продуктов, как соусы, супы и заправки. Увеличивая вязкость, HPMC обеспечивает правильную текстуру, гарантируя, что продукт не расслаивается и не становится слишком водянистым.

Эмульгирование — еще одна важная роль HPMC в пище. Он используется в таких продуктах, как майонез, заправки для салатов и мороженое, где он помогает удерживать фазы масла и воды вместе. Без HPMC эти продукты испытали бы разделение фаз, что привело бы к непоследовательным текстурам и плохому потребительскому опыту.

Стабилизация одинаково важен в производстве продуктов питания. В таких продуктах, как безглютеновые продукты и растительные рецептуры, ГПМЦ помогает поддерживать консистенцию и текстуру, обеспечивая продукт, который имитирует традиционные рецептуры, предлагая необходимые функциональные свойства. ГПМЦ также продлевает срок годности продуктов питания, предотвращая их преждевременную порчу.

| Применение в пищевой промышленности | Функция | Выгода |

|---|---|---|

| Загуститель | Увеличивает вязкость соусов, супов | Обеспечивает текстуру, предотвращает расслоение |

| Эмульгатор | Удерживает масло и воду во взвешенном состоянии | Обеспечивает однородную текстуру, стабильность |

| Стабилизатор | Сохраняет консистенцию, продлевает срок годности | Сохраняет качество продукта, улучшает текстуру |

5. Как ГПМЦ используется в строительной отрасли?

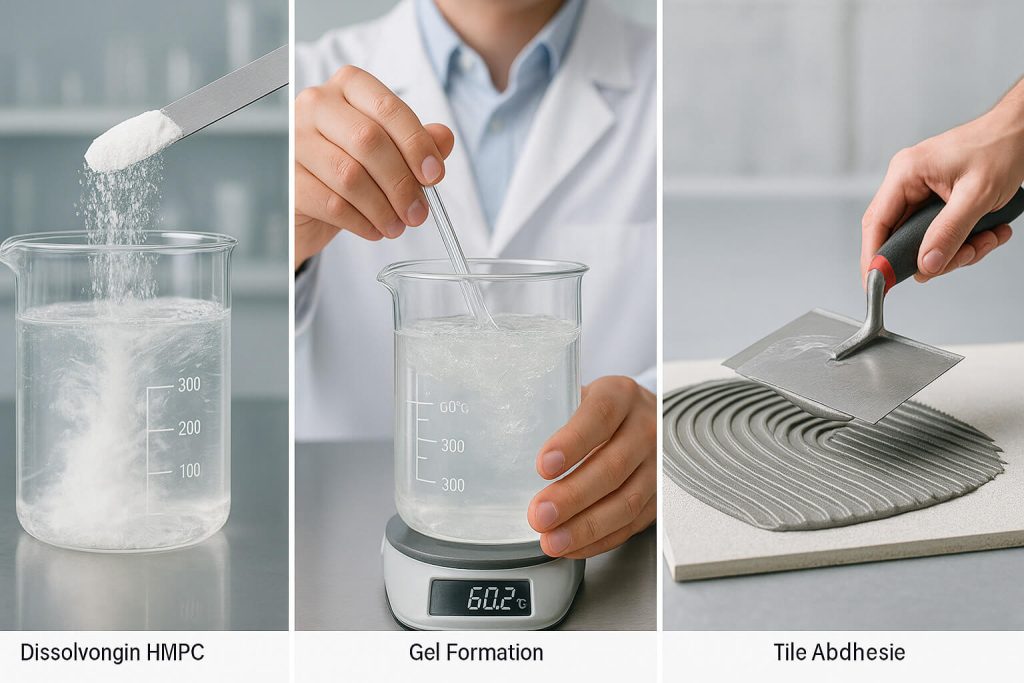

В строительной отрасли HPMC играет важную роль в качестве добавка в сухие строительные смеси, пластыри, и плиточный клей. Его основная функция - улучшить работоспособность этих материалов, что упрощает их смешивание, нанесение и распределение. Растворы и штукатурки часто могут стать слишком густыми или с ними трудно работать, но HPMC обеспечивает гладкую, однородную смесь, с которой легко работать.

Еще одна важная функция HPMC — задержка воды. В сухих смесях и штукатурках ГПМЦ помогает удерживать воду, предотвращая слишком быстрое высыхание смеси во время нанесения. Это обеспечивает правильное отверждение, гарантируя, что материал правильно схватится и образует прочные связи. Без надлежащего удержания воды материал может преждевременно высохнуть, что приведет к трещинам и снижению прочности.

Улучшение адгезии еще одно преимущество использования HPMC в строительстве. Он улучшает адгезионные свойства плиточных клеев, гарантируя, что плитка останется прочно на месте после нанесения. Это приводит к более длительному сроку службы установки и уменьшению проблем с обслуживанием в долгосрочной перспективе.

| Применение в строительстве | Функция | Выгода |

|---|---|---|

| Сухие строительные смеси | Улучшает обрабатываемость, предотвращает комкование | Легкое смешивание и нанесение |

| Пластыри | Улучшает удержание воды | Обеспечивает правильное отверждение, предотвращает появление трещин |

| Клеи | Улучшает адгезию и сцепление | Прочная, долговечная связь |

6. Как HPMC может способствовать внедрению устойчивых методов и зеленого производства?

В условиях растущих экологических проблем HPMC предлагает ряд ключевых преимуществ для отраслей, ищущих более устойчивые альтернативы. ГПМЦ является биоразлагаемым, что означает, что он распадается естественным образом, не нанося вреда окружающей среде. Эта биоразлагаемость делает HPMC привлекательным вариантом для компаний, стремящихся сократить свое воздействие на окружающую среду.

В строительство, HPMC способствует зеленые строительные материалы заменяя синтетические химикаты, которые могут быть неэкологичными. Использование HPMC помогает снизить зависимость от ингредиентов на основе нефти, способствуя устойчивости в строительстве.

В пищевая промышленность, HPMC является альтернатива на растительной основе на ингредиенты животного происхождения, такие как желатин, что соответствует растущему спросу на веганские и вегетарианские продукты. Заменяя эти ингредиенты на HPMC, производители могут производить более устойчивые, этичные варианты продуктов питания, которые удовлетворят более широкую потребительскую базу.

| Экологическая выгода | Описание | Приложение |

|---|---|---|

| Биоразлагаемость | Разлагается естественным образом в окружающей среде. | Экологичное строительство, экологически чистое производство продуктов питания |

| Экологичный | Устойчивая альтернатива синтетическим полимерам | Экологичные строительные материалы, устойчивые варианты питания |

7. Как можно адаптировать ГПМЦ для различных промышленных целей?

Одной из выдающихся особенностей HPMC является его способность быть настроенным для различных промышленных приложений. Производители могут изменять вязкость, скорость растворения, и степень замещения для адаптации HPMC к конкретным потребностям.

В фармацевтическая промышленность, регулируя скорость растворения позволяет создавать лекарственные формулы с контролируемым высвобождением. Это позволяет производителям разрабатывать лекарства, которые высвобождают свои активные ингредиенты медленно с течением времени, улучшая терапевтические результаты и снижая необходимость в частом дозировании.

В пищевая промышленность, регулируя вязкость ГПМЦ гарантирует, что продукт будет иметь желаемую текстуру, будь то загущение супа или эмульгирование заправки. строительство, настройка степень замещения помогает улучшить адгезию и удобоукладываемость сухих строительных смесей и клеев.

| Аспект настройки | Функция | Выгода |

|---|---|---|

| Контроль вязкости | Регулирует густоту растворов | Индивидуальная производительность для различных отраслей промышленности |

| Скорость растворения | Контролирует высвобождение лекарственного средства или скорость эмульгирования | Пролонгированное высвобождение, однородная текстура |

| Степень замещения | Влияет на растворимость и образование геля | Тонко настроенные свойства для конкретных нужд |

8. Каковы общие проблемы при использовании HPMC?

Хотя HPMC предлагает много преимуществ, существуют некоторые проблемы в его использовании. Одна из наиболее распространенных проблем — непоследовательное роспускПри работе с большими партиями может быть сложно обеспечить равномерное растворение ГПМЦ, что может привести к нестабильному качеству продукта.

Температурная чувствительность это еще одна проблема. Хотя HPMC стабилен в определенном диапазоне температур, чрезмерное тепло может деградировать полимер и снизить его эффективность. Необходимо соблюдать осторожность для поддержания правильных температур обработки.

Окончательно, вопросы стоимости и цепочки поставок может повлиять на доступность и цену HPMC. В зависимости от источника целлюлозы и степени модификации колебания цены и доступности могут повлиять на общую стоимость производства.

| Испытание | Причина | Решение |

|---|---|---|

| Непоследовательное роспуск | Неправильное смешивание, соотношение воды и полимера | Обеспечить надлежащие методы растворения, контроль качества |

| Температурная чувствительность | Разложение при высоких температурах | Поддержание оптимальных условий обработки |

| Проблемы с цепочкой поставок | Колебания цен на сырье |

и доступность | Найдите надежных поставщиков, оптимизируйте производство |

9. Существуют ли альтернативы ГПМЦ в различных областях применения?

Хотя ГПМЦ весьма эффективен, существуют альтернативные полимеры, выполняющие аналогичные функции. Метилцеллюлоза (МЦ) является одной из таких альтернатив, известной своей способностью образовывать гели при более высоких температурах. Однако гелеобразующая способность MC ограничивает его универсальность по сравнению с HPMC, что делает HPMC более предпочтительным выбором во многих приложениях.

Карбоксиметилцеллюлоза (КМЦ) является еще одной альтернативой, особенно используемой для изменения вязкости. КМЦ распространена в пищевой и фармацевтической промышленности, но не обладает гелеобразующими свойствами, которые делают ГПМЦ более адаптивной.

Несмотря на существование этих альтернатив, ГПМЦ остается популярным полимером благодаря сочетанию его свойств, включая растворимость в воде, образование геля, и контроль вязкости.

| Альтернатива | Основные характеристики | Приложение |

|---|---|---|

| Метилцеллюлоза | Гелеобразование при более высоких температурах | Продукты питания, фармацевтика |

| Карбоксиметилцеллюлоза | Контроль вязкости | Продукты питания, фармацевтика |

| ГПМЦ | Растворимость в воде, гелеобразование | Фармацевтика, строительство, продукты питания |

Заключение

В заключение, гидроксипропилметилцеллюлоза (ГПМЦ) является универсальным и важным полимером, который используется во многих отраслях промышленности благодаря своим уникальным свойствам. растворимость в воде, контроль вязкости, гелеобразующая способность, и термическая стабильность делают его бесценным ингредиентом в фармацевтике, пище и строительстве. Поскольку отрасли стремятся принять более устойчивые методы, HPMC биоразлагаемость и Экологически чистая природа только увеличивают его ценность. Несмотря на такие проблемы, как чувствительность к температуре и изменчивость цепочки поставок, преимущества HPMC намного перевешивают недостатки, что делает его выбором номер один для производителей по всему миру.

Часто задаваемые вопросы

Q1: Что такое гидроксипропилметилцеллюлоза (ГПМЦ)?

ГПМЦ — это полимер, полученный из целлюлозы, используемый в качестве связующего, эмульгатора и стабилизатора в различных отраслях промышленности, таких как фармацевтика, пищевая промышленность и строительство.

Q2: Как функционирует ГПМЦ в фармацевтических целях?

ГПМЦ выполняет функцию связующего вещества в таблетках и помогает контролировать высвобождение активных ингредиентов в составах с контролируемым высвобождением, обеспечивая равномерную доставку лекарственных средств.

Q3: Какую роль играет HPMC в пищевой промышленности?

ГПМЦ используется в качестве загустителя, эмульгатора и стабилизатора, улучшая текстуру и консистенцию пищевых продуктов и выступая в качестве веганской альтернативы традиционным ингредиентам, таким как желатин.

4-й квартал: Какую пользу HPMC приносит строительной отрасли?

В строительстве ГПМЦ улучшает обрабатываемость и адгезию растворов и клеев, а также помогает удерживать воду для лучшего отверждения и долговечности.

Q5: Существуют ли альтернативы ГПМЦ?

Такие альтернативы, как метилцеллюлоза и карбоксиметилцеллюлоза, обладают схожими свойствами, но ГПМЦ остается предпочтительным выбором благодаря своей универсальной функциональности и эффективности в широком спектре отраслей.