Controlled-release drug delivery systems have revolutionized pharmaceutical treatment by addressing the limitations of conventional dosage forms, including frequent dosing, fluctuating plasma levels, and poor patient compliance. At the heart of many successful controlled-release formulations lies hydroxypropyl methylcellulose (HPMC), a versatile polymer that has become the industry standard for creating robust matrix systems. Pharmaceutical manufacturers face significant challenges in developing controlled-release products that maintain consistent drug release across varying physiological conditions while ensuring manufacturability and stability. HPMC offers a solution through its unique hydration properties, forming a predictable gel barrier that modulates drug diffusion regardless of pH variations or mechanical stress. This article examines the fundamental principles, formulation strategies, and technical considerations for leveraging HPMC’s full potential in controlled-release systems, drawing on decades of research and commercial application in products ranging from cardiovascular medications to analgesics.

1. What Is HPMC And Why Is It Critical For Controlled-Release Drug Delivery?

Hydroxypropyl methylcellulose (HPMC), also known as hypromellose, is a semi-synthetic, non-ionic cellulose ether derived from natural cellulose through chemical modification. Its molecular structure features a cellulose backbone with methoxy and hydroxypropyl substituents, creating a polymer with unique physicochemical properties ideal for controlled drug delivery applications.

But here’s what makes it truly exceptional: HPMC forms a predictable hydrophilic gel layer when exposed to aqueous environments, creating a diffusion barrier that remains stable across varying physiological conditions. This remarkable consistency in performance sets it apart from many other polymers that may be sensitive to pH changes or enzymatic degradation in the gastrointestinal tract.

| Свойство | Characteristic | Benefit in Controlled Release |

|---|---|---|

| Hydrophilicity | Forms hydrated gel layer upon contact with water | Creates diffusion barrier for controlled drug release |

| Viscosity range | Available in multiple grades (3-200,000 mPa·s) | Enables tailoring of release rates from hours to 24+ hours |

| pH independence | Stable across physiological pH range (1-9) | Consistent performance throughout GI transit |

| Non-ionic nature | Minimal interaction with ionic drugs and excipients | Compatible with wide range of active ingredients |

| Термическое гелеобразование | Forms stronger gel at elevated temperatures | Provides robust performance at body temperature |

Compared to other polymers used in controlled-release formulations, HPMC offers several distinct advantages:

- Unlike pH-dependent polymers, HPMC maintains consistent performance regardless of gastrointestinal pH variations

- Compared to hydrophobic matrix formers, HPMC provides more predictable erosion kinetics and complete drug release

- Unlike natural gums, HPMC exhibits minimal batch-to-batch variation and better stability

- Compared to synthetic polymers, HPMC offers better regulatory acceptance and established safety profile

2. How Does The HPMC Matrix System Control Drug Release Mechanisms?

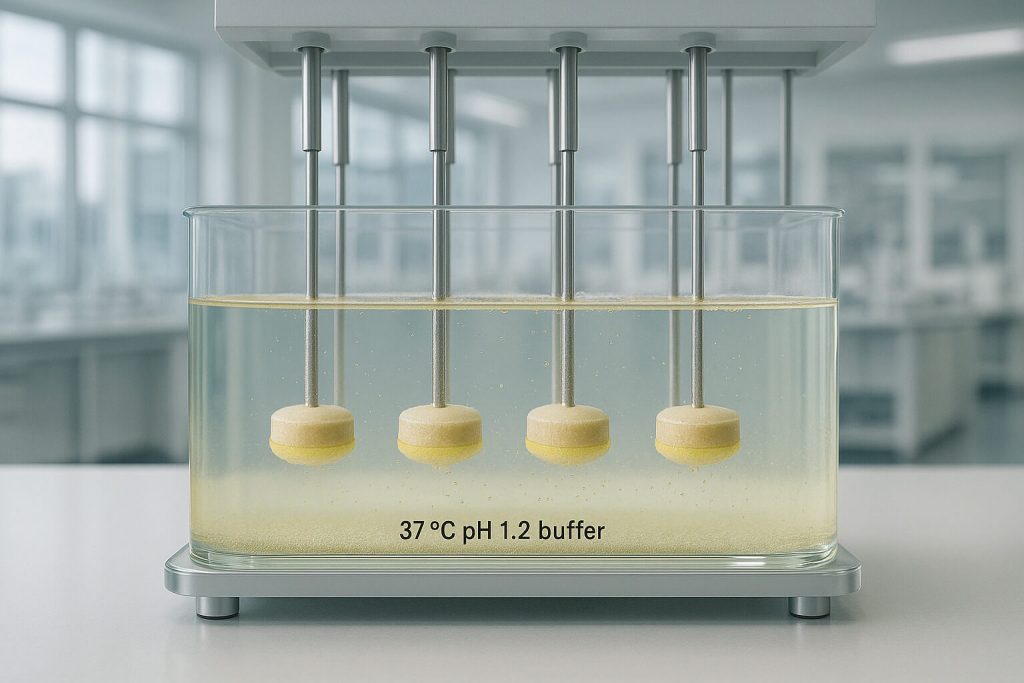

The HPMC matrix system represents one of the most elegant and reliable approaches to controlled drug delivery, operating through a complex interplay of polymer hydration, gel formation, and drug diffusion processes.

This is where the science gets fascinating: When an HPMC matrix tablet contacts aqueous media, it doesn’t simply dissolve or disintegrate like conventional tablets. Instead, a dynamic process unfolds where water penetration creates distinct fronts within the tablet—a fully hydrated gel layer, a partially hydrated swelling region, and a dry core—each playing a crucial role in controlling drug release over extended periods.

The hydration and gel formation process follows several distinct phases:

- Initial water penetration into the tablet surface

- Polymer chain relaxation as water acts as a plasticizer

- Formation of a viscous gel layer as polymer concentration exceeds entanglement threshold

- Continued water penetration, expanding the gel layer thickness

- Gradual erosion of the outer gel layer while new gel forms at the advancing water front

| Phase | Time Frame | Physical State | Механизм выпуска |

|---|---|---|---|

| Initial hydration | 0-30 minutes | Surface gel formation | Burst release from surface |

| Gel layer establishment | 30 min – 2 hours | Defined gel layer around dry core | Fickian diffusion through gel |

| Steady state | 2-12 часов | Dynamic equilibrium between hydration and erosion | Combined diffusion and erosion |

| Terminal phase | >12 hours | Complete hydration, erosion dominates | Primarily erosion-controlled |

The primary mechanisms controlling drug release from HPMC matrices include Fickian diffusion (drug molecules migrate through the gel layer along a concentration gradient), polymer relaxation (swelling creates additional space for drug movement), erosion (gradual dissolution of the outer gel layer), and dissolution (for poorly soluble drugs).

Mathematical models describing HPMC-based drug release help quantify these mechanisms, with the Higuchi model (Q = k·t^(1/2)) describing diffusion-controlled release and the Korsmeyer-Peppas model (Q = k·t^n) indicating the release mechanism based on the value of n.

3. What Impact Do Different HPMC Grades Have On Release Profiles?

The pharmaceutical market offers a diverse range of HPMC grades, each with specific properties that significantly impact drug release kinetics. Selecting the appropriate grade is perhaps the most fundamental decision in developing HPMC-based controlled-release formulations.

Here’s what experienced formulators understand: While viscosity grade often receives the most attention, the substitution type of HPMC can have equally profound effects on release performance. The ratio of methoxy to hydroxypropyl groups affects hydration rate, gel strength, and erosion characteristics—sometimes more significantly than viscosity differences alone.

| Сорт ГПМЦ | Nominal Viscosity (mPa·s) | Тип замены | Typical Release Duration |

|---|---|---|---|

| E5, E6 | 5-6 | 2910 | 4-6 hours |

| E15, E50 | 15-50 | 2910 | 6-8 hours |

| K100LV | 100 | 2208 | 8-12 часов |

| К4М | 4,000 | 2208 | 12-16 hours |

| К15М | 15,000 | 2208 | 16-20 hours |

| К100М | 100,000 | 2208 | 20-24+ hours |

Viscosity grade effects on release duration and kinetics:

- Low viscosity grades (3-100 mPa·s) form weaker gel layers that erode more rapidly, with release primarily controlled by erosion, suitable for shorter-duration products (4-8 hours)

- Medium viscosity grades (100-4,000 mPa·s) balance diffusion and erosion mechanisms, providing robust gel structure with moderate resistance to diffusion, ideal for 12-hour release profiles

- High viscosity grades (4,000-100,000 mPa·s) form very strong gel layers resistant to erosion, with release primarily controlled by diffusion through thick gel, suitable for once-daily (24-hour) formulations

Substitution type also influences hydration and erosion rates, with higher methoxy content (2910 types) providing more rapid initial hydration, lower gel strength, and faster erosion rate, while lower methoxy content (2208 types) offers slower initial hydration, stronger gel formation, and more resistance to erosion.

4. How Can Formulation Variables Optimize HPMC-Based Controlled Release?

Beyond HPMC grade selection, numerous formulation variables can be manipulated to fine-tune release profiles and optimize overall product performance.

And this is the key insight: HPMC concentration in the formulation has a non-linear relationship with release rate. This means that small changes in concentration can have disproportionate effects on release profiles, particularly within certain critical ranges. Mastering this relationship allows formulators to make precise adjustments to achieve target release kinetics.

| Концентрация ГПМЦ | Impact on Release | Formulation Considerations |

|---|---|---|

| 10-20% | Discontinuous gel layer, erosion-dominated | Suitable for higher viscosity grades only |

| 20-35% | Continuous gel layer, balanced mechanisms | Optimal range for most formulations |

| 35-50% | Very thick gel layer, diffusion-dominated | May cause incomplete release for poorly soluble drugs |

| >50% | Extremely slow release, potential for zero-order | Rarely used due to tablet size constraints |

Tablet geometry and surface area/volume ratio significantly impact release kinetics:

- Conventional round tablets provide balanced surface area/volume ratio and predictable, consistent release

- Elongated or oval tablets have higher surface area/volume ratio, resulting in faster initial release rate

- Multi-layer tablets have reduced surface area for drug release, enabling directional or pulsatile release

- Mini-tablets or pellets have very high surface area/volume ratio, with rapid gel formation

The influence of excipients on matrix performance can be strategically leveraged:

- Soluble fillers (lactose, mannitol) create channels in the gel layer, increase water penetration rate, and accelerate drug release

- Insoluble fillers (microcrystalline cellulose, dicalcium phosphate) create tortuous diffusion pathways, reduce effective diffusion coefficient, and slow drug release

- Surfactants improve wetting of hydrophobic drugs but may weaken gel structure

- Electrolytes affect HPMC hydration through ionic interactions and can cause “salting out” at high concentrations

Processing parameters like compression force, mixing time and method, and granulation versus direct compression also affect release consistency and must be carefully controlled.

5. What Challenges Exist When Developing HPMC Controlled-Release Products?

Despite HPMC’s versatility and robust performance, developing successful controlled-release products using this polymer presents several significant challenges.

This is what separates success from failure: The food effect on HPMC matrices can dramatically alter drug release and absorption in vivo, potentially negating carefully designed in vitro performance. Understanding and mitigating this effect is often the difference between a successful product and one that fails in clinical trials due to high variability.

| Physiological Factor | Impact on HPMC Performance | Стратегия смягчения последствий |

|---|---|---|

| Food-induced delay in gastric emptying | Extended exposure to gastric conditions | Use higher viscosity grades resistant to acidic hydrolysis |

| Increased fluid volume with meals | Accelerated hydration | Increase HPMC concentration or use higher viscosity grade |

| Mechanical forces during digestion | Physical stress on gel layer | Strengthen gel with complementary polymers |

| Bile salts and enzymes | Potential interaction with gel structure | Consider protective coating or additional excipients |

| GI transit time variability | Inconsistent residence time in absorption window | Design for complete release before colon arrival |

Stability considerations include moisture sensitivity (HPMC absorbs atmospheric moisture, requiring appropriate packaging), temperature effects (storage at elevated temperatures may affect polymer properties), and aging effects (relaxation of compression forces over time).

Scale-up challenges from laboratory to production include equipment differences (different mixing efficiency and shear forces), process parameter sensitivity (compression force effects on tablet density and hydration), and raw material variability (batch-to-batch variation in HPMC properties).

6. How Is HPMC Combined With Other Polymers For Modified Release Systems?

While HPMC alone can create effective controlled-release systems, combining it with other polymers opens up possibilities for more sophisticated drug delivery approaches.

What innovative formulators recognize: The synergistic interactions between HPMC and complementary polymers can create release profiles that follow specific therapeutic requirements rather than the typical first-order kinetics of single-polymer systems. This approach allows for precise chronotherapy, targeting specific absorption windows, or matching complex pharmacokinetic needs.

| Polymer Combination | Release Modification | Преимущество применения |

|---|---|---|

| HPMC + Ethylcellulose | Reduced release rate, approach to zero-order | Once-daily formulations of highly soluble drugs |

| HPMC + Carbomers | Bioadhesive properties, prolonged GI retention | Enhanced bioavailability for absorption window-limited drugs |

| HPMC + Polyethylene oxide | Synergistic gel strength, abuse-deterrence | Tamper-resistant opioid formulations |

| HPMC + Xanthan gum | Enhanced robustness against food effects | Reduced variability in fed/fasted conditions |

| HPMC + Polyvinylpyrrolidone | Improved solubilization of poorly soluble drugs | Enhanced dissolution rate within controlled-release matrix |

HPMC can be combined with pH-dependent polymers for targeted delivery:

- HPMC + HPMCAS creates delayed-onset, extended-release profiles for targeting drugs to the small intestine

- HPMC + Methacrylic acid copolymers provides site-specific release followed by controlled release

- HPMC + Sodium alginate forms a dual barrier in acidic environment for pH-dependent release modulation

Dual matrix systems for biphasic or pulsatile release include layered tablets (HPMC layer for extended release, immediate-release layer for loading dose), core-shell systems (HPMC core with different polymer coating), and matrix-in-matrix systems (HPMC matrix containing discrete domains of different release characteristics).

Заключение

HPMC stands as the cornerstone polymer in modern controlled-release drug delivery, offering unparalleled versatility and robust performance across diverse applications. Its unique ability to form a predictable gel barrier that modulates drug diffusion, regardless of physiological variables, has established it as the gold standard for extended-release matrix systems. The key to successful implementation lies in understanding the interplay between HPMC grade selection, formulation variables, and processing parameters—all of which significantly impact release kinetics and in vivo performance.

For pharmaceutical scientists and formulators, mastering the nuances of HPMC-based systems—from viscosity grade selection to polymer combinations—provides powerful tools for addressing specific therapeutic challenges. Whether developing a simple once-daily formulation or a complex modified-release system, the principles and strategies discussed offer a framework for rational formulation design and troubleshooting.

As drug delivery technology continues to advance, HPMC’s fundamental role appears secure, with ongoing innovations focusing on combining it with complementary materials to achieve increasingly sophisticated release profiles. By leveraging HPMC’s well-established regulatory status, consistent performance, and adaptability, pharmaceutical manufacturers can continue developing the next generation of controlled-release products that enhance patient compliance and therapeutic outcomes.

Часто задаваемые вопросы

Q1: How does drug solubility affect release from HPMC matrices?

Drug solubility profoundly influences release mechanisms from HPMC matrices. Highly water-soluble drugs primarily release through diffusion through the gel layer, creating channels that can accelerate release and potentially cause dose dumping if not properly controlled. These drugs typically require higher viscosity HPMC grades (K15M, K100M) or higher polymer concentrations (30-40%) to maintain extended release. Conversely, poorly soluble drugs often exhibit dissolution-limited release, where the rate of drug dissolution within the matrix, rather than diffusion through the gel, becomes the rate-limiting step. For these compounds, lower viscosity HPMC grades and solubility-enhancing excipients may be beneficial.

Q2: What are the key differences between HPMC and other hydrophilic matrix formers?

HPMC differs from other hydrophilic matrix formers in several important aspects. Unlike xanthan gum and other natural polymers, HPMC offers consistent batch-to-batch performance with minimal variability. Compared to polyethylene oxide (PEO), HPMC exhibits better stability against oxidative degradation and less sensitivity to mechanical stress. While sodium carboxymethylcellulose (CMC) is highly sensitive to pH and ionic strength due to its anionic nature, HPMC’s non-ionic character provides consistent performance across varying physiological conditions. HPMC also offers broader global regulatory acceptance and a longer history of use in approved products compared to many alternative polymers.

Q3: How do manufacturing methods impact HPMC matrix performance?

Manufacturing methods significantly impact HPMC matrix performance through their effects on polymer distribution, hydration, and tablet microstructure. Direct compression typically results in faster initial release rates compared to wet granulation, as the latter creates a more homogeneous distribution of HPMC throughout the tablet. Wet granulation can also partially pre-hydrate HPMC, reducing the initial burst release often observed with direct compression. Compression force also plays a crucial role—higher compression forces create denser tablets with reduced porosity, slowing water penetration and initial hydration rates. The optimal manufacturing method depends on drug properties, dose, and target release profile.

Q4: Can HPMC controlled-release formulations be used for all types of drugs?

While HPMC is remarkably versatile, it is not universally suitable for all drugs. HPMC-based systems work best for drugs with moderate solubility (0.1-10 mg/mL) and moderate to high permeability. Extremely high-solubility compounds may release too rapidly despite high HPMC concentrations, potentially requiring combination with hydrophobic polymers. Very poorly soluble drugs may not achieve complete release within the gastrointestinal transit time, as their dissolution becomes rate-limiting rather than diffusion through the HPMC gel. Drugs with narrow absorption windows in the upper GI tract may not be ideal candidates unless combined with gastroretentive technologies.

Q5: What recent innovations have improved HPMC-based controlled release systems?

Recent innovations in HPMC-based controlled release systems include the development of specialized grades with modified substitution patterns that offer enhanced functionality for specific applications. Advanced multi-layer and core-shell technologies combining HPMC with other polymers have enabled precise chronotherapeutic delivery targeting specific release windows. 3D printing has emerged as a novel manufacturing approach, allowing complex internal geometries that create predetermined release pathways through HPMC matrices. Combination products incorporating HPMC with in situ gelling polymers have improved gastroretention for narrow absorption window drugs. For abuse-deterrent formulations, high-viscosity HPMC combined with proprietary polymer networks has created tamper-resistant systems that maintain extended-release properties despite physical manipulation attempts.