Dissolving Hydroxypropyl Methylcellulose (HPMC) in water requires specific techniques to achieve optimal results. Many manufacturing professionals struggle with this process, experiencing issues like clumping, incomplete dissolution, or inconsistent final properties. This article provides a comprehensive guide to properly dissolve HPMC in water, helping you avoid common pitfalls and optimize your production processes. Our technical expertise comes from years of industry experience and collaboration with leading HPMC manufacturers.

1. What is HPMC and Why is it Challenging to Dissolve?

HPMC (Hydroxypropyl Methylcellulose) is a semi-synthetic, inert polymer derived from cellulose. It consists of cellulose backbones modified with hydroxypropyl and methyl groups, creating a versatile compound widely used across multiple industries. Its unique chemical structure gives it excellent film-forming capabilities, binding properties, and thickening abilities.

Но вот в чем дело: HPMC’s dissolution behavior is counterintuitive compared to most water-soluble polymers.

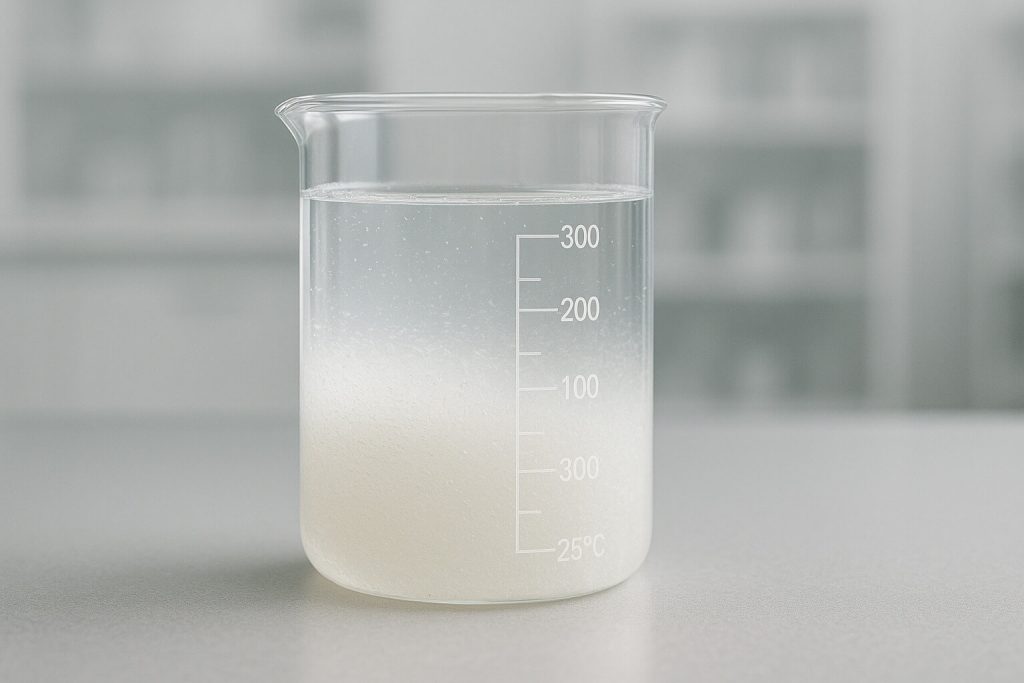

The primary challenge in dissolving HPMC stems from its unique hydration mechanism. When HPMC particles contact water, they quickly form a gel layer on their surface. This gel layer can prevent water from penetrating to the core of the particles, resulting in clumps or “fish eyes” – partially hydrated particles with dry centers.

HPMC finds applications in numerous industries:

| Промышленность | Применение HPMC |

|---|---|

| Фармацевтическая | Tablet coating, controlled release matrices, binders |

| Строительство | Cement additives, renders, tile adhesives |

| Еда | Thickener, stabilizer, emulsifier |

| Личная гигиена | Rheology modifier in shampoos and lotions |

| Краски и покрытия | Thickener, film former, protective colloid |

Several factors affect HPMC solubility:

- Temperature: HPMC exhibits inverse solubility – it dissolves better in cold water than hot

- Particle size: Finer particles hydrate faster but are more prone to agglomeration

- Viscosity grade: Higher viscosity grades require more careful dissolution techniques

- Substitution type: The ratio of hydroxypropyl to methyl substitution affects solubility

- Water quality: Mineral content and pH can impact dissolution efficiency

Traditional dissolution methods often fail because they don’t account for HPMC’s unique thermal gelation properties. Many operators attempt to dissolve HPMC like other polymers by adding it to hot water, which causes immediate gelation and prevents proper dispersion.

2. What Water Temperature is Optimal for HPMC Dissolution?

The temperature of water plays a crucial role in successfully dissolving HPMC. Unlike most materials that dissolve better in hot water, HPMC exhibits a unique property called thermal gelation.

Here’s the critical point: HPMC has a specific temperature threshold (typically between 65-85°C depending on the grade) above which it becomes insoluble and forms a gel.

This inverse solubility behavior means cold water is actually optimal for HPMC dissolution. The recommended temperature range for initial dispersion is 5-15°C (41-59°F). At these lower temperatures, HPMC particles hydrate more slowly, allowing time for proper dispersion before significant viscosity development occurs.

The dissolution mechanism differs significantly between cold and hot water:

| Растворение в холодной воде | Растворение в горячей воде |

|---|---|

| Slower initial hydration | Immediate surface gelation |

| Allows time for proper dispersion | Forms barrier preventing further hydration |

| Gradual viscosity development | Clumping and “fish eye” formation |

| Complete and uniform hydration | Incomplete and inconsistent hydration |

| Requires more time but yields better results | Faster but often produces poor quality solutions |

Temperature control techniques during dissolution include:

- Pre-cooling water before HPMC addition

- Using ice baths for laboratory-scale preparations

- Employing jacketed vessels with cooling capabilities for industrial processes

- Monitoring temperature throughout the dissolution process

- Adjusting agitation speed to control heat generation from mechanical energy

3. What is the Step-by-Step Process for Dissolving HPMC?

A systematic approach to HPMC dissolution ensures consistent, high-quality results. Follow this detailed process to achieve optimal dissolution:

Preparation of Materials and Equipment

Before beginning the dissolution process, gather all necessary materials and equipment:

| Required Materials | Цель |

|---|---|

| HPMC powder | Primary ingredient to be dissolved |

| Cold water (5-15°C) | Initial dispersion medium |

| Hot water (>85°C) | For the hot/cold technique (if used) |

| Mixing vessel | Container for dissolution process |

| Appropriate agitator | Provides necessary shear for dispersion |

| Temperature monitoring device | Ensures optimal temperature conditions |

Want to know the secret to success? Proper preparation prevents poor performance.

Пошаговый процесс растворения

- Cold Water Dispersion Method:

- Cool water to 5-15°C

- Begin agitation to create a vortex

- Slowly add HPMC powder to the vortex edge

- Continue agitation until all particles are wetted

- Allow hydration for 30-60 minutes with continued agitation

- Gradually warm to room temperature if needed for the application

- Hot/Cold Technique (Alternative Method):

- Heat approximately 1/3 of the required water to >85°C

- Add HPMC powder to the hot water with vigorous agitation

- Immediately add the remaining 2/3 of water as cold as possible

- Continue agitation until completely dissolved

The hot/cold technique works because the hot water prevents initial hydration while allowing dispersion, and the subsequent cold water shock enables proper hydration without clumping.

| Dissolution Stage | Ключевые соображения |

|---|---|

| Initial dispersion | Prevent agglomeration through proper addition technique |

| Wetting phase | Ensure all particles are individually wetted |

| Hydration period | Allow sufficient time for complete hydration |

| Final adjustment | Adjust temperature to application requirements |

Common process issues and troubleshooting:

- Clumping: Increase agitation speed and add HPMC more slowly

- Foam formation: Reduce agitation speed or use a different impeller design

- Incomplete dissolution: Extend hydration time or improve initial dispersion

4. How Do Different HPMC Grades Affect Dissolution Behavior?

HPMC is available in various grades that differ in viscosity, substitution type, and particle size. These differences significantly impact dissolution behavior and must be considered when developing your process.

Правда в том, что: Not all HPMC grades dissolve the same way, and understanding these differences is crucial for success.

Viscosity Grades and Dissolution Characteristics

HPMC viscosity grades typically range from 3 mPa·s to 100,000 mPa·s (measured at 2% concentration in water at 20°C). Higher viscosity grades:

- Require more careful dispersion techniques

- Take longer to fully hydrate

- Are more prone to clumping during dissolution

- Need more vigorous agitation for proper dispersion

| Диапазон вязкости | Dissolution Characteristics | Типичные применения |

|---|---|---|

| Low (3-100 mPa·s) | Dissolves relatively easily, less prone to clumping | Tablet coatings, thin films |

| Medium (100-10,000 mPa·s) | Moderate dissolution difficulty, requires good technique | Controlled release matrices, adhesives |

| High (10,000-100,000 mPa·s) | Challenging to dissolve, highly prone to clumping | Thickeners, construction products |

Substitution Types and Particle Size

The ratio of hydroxypropyl to methyl substitution affects:

- Thermal gelation temperature

- Hydration rate

- Поверхностная активность

- Compatibility with other ingredients

For example, HPMC E-type typically has a higher methoxyl content and lower hydroxypropyl content, resulting in lower thermal gelation temperatures compared to K-types.

HPMC is available in different particle size distributions:

- Standard grades

- Fine powder grades

- Granular grades

Finer particles hydrate more quickly but are more prone to agglomeration. Granular grades offer improved flow properties and reduced dust but may take longer to fully dissolve.

Industry-specific considerations also play a role in grade selection:

- Pharmaceutical applications often require specific grades that meet regulatory requirements

- Construction applications may prioritize delayed hydration for improved workability

- Food applications require food-grade HPMC with appropriate certifications

5. What Equipment Provides the Best HPMC Dissolution Results?

The right equipment is essential for achieving optimal HPMC dissolution. Equipment selection depends on scale, required solution properties, and production constraints.

Consider this: Even the highest quality HPMC will perform poorly if dissolved with inadequate equipment.

Laboratory-Scale Equipment

For small-scale preparations (up to 20 liters), consider:

| Тип оборудования | Преимущества | Ограничения |

|---|---|---|

| Верхние мешалки | Adjustable speed, various impeller options | Limited shear capability |

| Смесители с высоким сдвиговым усилием | Excellent dispersion, reduced dissolution time | Potential for overheating |

| Magnetic stirrers | Simple operation, good for low viscosity | Insufficient for higher viscosities |

| Homogenizers | Superior particle dispersion | Expensive, potential for air incorporation |

Laboratory equipment recommendations:

- Use vessels with at least 30% headspace to accommodate vortex formation

- Select impellers that create both radial and axial flow

- Consider jacketed vessels for temperature control

- Use variable speed drives to adjust agitation intensity

Industrial-Scale Systems

For production-scale operations, options include:

- Batch tank with agitator for flexibility and multiple product types

- Continuous inline mixers for high volume, consistent production

- High-shear mixing systems for difficult-to-dissolve grades

- Powder induction systems for dust reduction and operator safety

Key features to look for in industrial equipment:

- Temperature control capabilities

- Appropriate impeller design for powder incorporation

- Variable speed capability

- Clean-in-place features for pharmaceutical or food applications

- Dust containment systems for operator safety

A cost-benefit analysis should consider:

- Initial equipment investment

- Operating costs (energy, labor)

- Maintenance requirements

- Production efficiency gains

- Product quality improvements

6. How Can You Verify Complete HPMC Dissolution?

Ensuring complete HPMC dissolution is critical for product performance. Incomplete dissolution can lead to inconsistent viscosity, poor film formation, and product defects.

The reality is: Visual inspection alone is often insufficient to guarantee complete dissolution.

Visual Inspection Techniques

Initial assessment can be performed visually:

- Check for clarity (depending on concentration and grade)

- Look for undissolved particles or “fish eyes”

- Assess solution uniformity

- Observe flow behavior

For more reliable visual assessment:

- Examine thin films of the solution against a dark background

- Use polarized light to identify undissolved particles

- Check for consistency when pouring or stirring

Analytical Testing Methods

For critical applications, analytical methods provide more definitive results:

| Test Method | What It Measures | Преимущества |

|---|---|---|

| Viscosity measurement | Solution viscosity at defined shear rate | Quantitative, sensitive to dissolution completeness |

| Анализ размера частиц | Presence of undissolved particles | Detects particles invisible to naked eye |

| Turbidity measurement | Solution clarity | Objective measurement of solution clarity |

| Microscopic examination | Direct visualization of particles | Detailed assessment of any undissolved material |

Quality Control Parameters

Establish specifications for:

- Viscosity (at defined temperature and shear rate)

- pH (if relevant to application)

- Clarity/turbidity

- Absence of visible particles

- Functional performance tests specific to application

To maintain consistency across production batches:

- Document dissolution parameters (temperature, time, agitation speed)

- Standardize raw material specifications

- Implement in-process testing at defined intervals

- Maintain equipment calibration and performance

7. What Are the Common Mistakes When Dissolving HPMC?

Despite best efforts, several common mistakes can compromise HPMC dissolution. Recognizing and avoiding these errors is essential for consistent results.

Let me be frank: Most HPMC dissolution failures stem from these preventable mistakes.

Incorrect Temperature Management

Temperature-related errors include:

- Using water that’s too warm for initial dispersion

- Failing to monitor temperature throughout the process

- Heating the solution before complete hydration

- Not accounting for temperature increase from mechanical agitation

- Improper storage of the final solution (temperature fluctuations)

| Temperature Error | Последствие | Prevention |

|---|---|---|

| Too warm initially | Immediate gelation and clumping | Pre-cool water to 5-15°C |

| Unmonitored process | Непоследовательные результаты | Use temperature monitoring |

| Premature heating | Incomplete hydration | Allow full hydration time before heating |

| Mechanical heating | Localized gelation | Adjust agitation speed, use cooling |

Other Common Mistakes

- Слишком быстрое добавление HPMC

- Insufficient agitation during addition

- Adding HPMC directly to still water

- Using inappropriate agitator design

- Attempting to dissolve too high a concentration at once

- Incompatibility with other ingredients in formulation

- Scaling issues when moving from laboratory to production scale

To prevent agglomeration:

- Create a proper vortex before adding powder

- Add HPMC slowly at the vortex edge

- Consider using the hot/cold technique for difficult grades

- Pre-blend HPMC with other dry ingredients when possible

- Use appropriate agitator design for powder incorporation

Complete HPMC hydration requires:

- Adequate initial dispersion (high intensity)

- Sufficient hydration time (typically 30-60 minutes minimum)

- Appropriate agitation throughout the hydration period

- Patience – rushing the process invariably leads to problems

Заключение

Successfully dissolving HPMC in water requires understanding its unique properties and following proper techniques. The key factors for optimal dissolution include using cold water for initial dispersion, employing appropriate agitation, allowing sufficient hydration time, and selecting equipment suited to your specific HPMC grade and scale of operation.

By avoiding common mistakes like improper temperature management, insufficient dispersion, and inadequate mixing, you can achieve consistent, high-quality HPMC solutions. Remember that different grades require adjusted approaches, and verification of complete dissolution is essential for product performance.

For manufacturing professionals working with HPMC, mastering these dissolution techniques will improve product quality, reduce waste, and enhance production efficiency. We encourage you to apply these principles in your operations and contact us if you need further assistance with your specific HPMC applications.

Раздел часто задаваемых вопросов

Q1: Can HPMC be dissolved directly in hot water?

No, HPMC should not be dissolved directly in hot water. HPMC exhibits thermal gelation, forming a gel layer when exposed to hot water (typically above 65-85°C depending on the grade). This gel layer prevents water penetration to the particle core, resulting in incomplete dissolution and clumping. Instead, use cold water for initial dispersion or employ the hot/cold technique where HPMC is first dispersed in hot water followed immediately by addition of cold water.

Q2: How long does it typically take to completely dissolve HPMC?

Complete HPMC dissolution typically takes 30-60 minutes for standard grades at moderate concentrations (1-2%). However, this time varies significantly based on several factors: higher viscosity grades may require 1-2 hours or more; higher concentrations extend dissolution time; finer particle grades dissolve faster than granular types; and more efficient mixing equipment can reduce dissolution time. Always verify complete dissolution through appropriate testing rather than relying solely on time.

Q3: What is the maximum concentration of HPMC that can be dissolved in water?

The maximum practical concentration of HPMC in water depends on the specific grade and application requirements. Low viscosity grades can typically be dissolved up to 10-15% concentration, while high viscosity grades become extremely difficult to work with above 2-3%. The practical limit is often determined by the resulting solution viscosity and the capabilities of available mixing equipment. For concentrations above 5%, consider using specialized high-shear mixing equipment and staged addition techniques.

Q4: Does pH affect HPMC dissolution and stability?

HPMC is generally stable across a wide pH range (3-11), making it versatile for various applications. However, extreme pH conditions can affect dissolution behavior and long-term stability. Very acidic conditions (pH < 3) may slow hydration and potentially cause hydrolysis during extended storage. Very alkaline conditions (pH > 11) can affect certain grades, particularly those with specific substitution patterns. For optimal results, maintain pH within the 4-9 range during dissolution unless your application specifically requires more extreme conditions.

Q5: Can additives improve HPMC dissolution efficiency?

Yes, certain additives can improve HPMC dissolution efficiency. Surfactants at low concentrations (0.1-0.5%) can enhance wetting and reduce agglomeration. Anti-foaming agents may be beneficial when high-speed agitation causes excessive foaming. Some manufacturers offer specially modified HPMC grades with improved dispersibility. However, always verify compatibility of any additives with your specific application, as they may affect final product properties. For food or pharmaceutical applications, ensure any additives meet relevant regulatory requirements.